An Introduction to Gauged Brickwork

Ever wondered what makes historical buildings look so impeccable? What gives modern constructions that detailed, uniform appearance?

The answer to both these questions often lies in a technique called “gauged brickwork”.

Brick masonry might seem basic; however, this form of brickwork is anything but ordinary. In this blog, we will explore this versatile construction practice. We’ll describe what gauged brickwork is, how it relies on a brick gauging system, and its aesthetic and practical application in forming gauged brick arches.

Gauged brickwork isn’t just about giving a building a clean, organized look – you’ll learn about the intricate details involved in this method. From the precision required in cutting each brick to the exact same size, to the types of materials and tools used, we’ll walk you through the technicalities.

We’ll explore how brick gauging enhances the efficiency of construction by standardizing measurements and improving quality. Finally, we’ll take a fascinating look at the creation of gauged brick arches, a powerful blend of structural support and architectural beauty.

Ready to get started? Let’s dive in!

Table of Contents

Understanding Gauged Brickwork in Construction

Definition of Gauged Brickwork

Gauged brickwork refers to a high-quality type of brick masonry where the bricks are carefully cut and finished to the exact same dimensions, ensuring a precise and uniform appearance. This technique is often used in decorative and detailed projects where aesthetics are a high priority.

Key Characteristics

- Precision: Each brick is cut to the same size and shape.

- Aesthetics: Provides a uniform and visually appealing finish.

- Labor-Intensive: Requires skilled labor to shape and set the bricks properly.

Materials and Tools Used

- High-Quality Bricks: Typically made of clay and selected for their uniform texture.

- Specialized Cutting Tools: Such as brick saws and grinders.

- Gauging Tools: To ensure each brick meets the precise dimensions.

Applications of Gauged Brickwork

- Ornamental Facades: For buildings requiring intricate detailing.

- Historical Restorations: To match the detailed craftsmanship of older structures.

- Architectural Elements: Like arches, cornices, and decorative panels.

Process Overview

| Step | Description |

|---|---|

| 1. Selection | Choose high-quality bricks that match the project’s requirements. |

| 2. Cutting | Use specialized tools to cut bricks to the exact size and shape. |

| 3. Gauging | Check each brick with gauging tools to ensure uniformity. |

| 4. Laying | Set the bricks in place with precision, often using fine mortar. |

| 5. Finishing | Apply finishing touches to ensure a smooth and uniform surface. |

Benefits of Gauged Brickwork

- Enhanced Appearance: Creates a visually appealing and professional look.

- Durability: High-quality bricks and precise construction lead to long-lasting structures.

- Customization: Allows for intricate designs and detailed architectural elements.

Reasons for Use

- Historical Significance: Preserves the traditional methods used in historical buildings.

- Architectural Integrity: Ensures that modern additions blend seamlessly with existing structures.

- Desirable Aesthetic: Preferred for premium constructions where appearance is important.

Exploring Brick Gauges System

The Concept of Brick Gauges

The brick gauging system refers to the process of maintaining consistent dimensions in brick masonry. It signifies how many bricks are used over a particular height or length – typically a measurement of distance.

This measurement method in brickwork allows for construct uniformity and balance in the structural strength across the building project. The standard gauge is the determinant of the number of courses – horizontal layers of bricks-, generally based on an 8-foot or 2438 mm standard wall height.

Types of Brick Gauges

A brick gauge can either be an imperial gauge or a metric gauge. The imperial gauge is traditional and is based on the size of a normal “brick unit”.

The metric gauge is modern and standardized across the European Union, adjusting the standard brick unit’s size to fit within the metric system.

Importance of Brick Gauging

- Uniformity: Brick gauging promotes proportional look and consistent sizing, especially for large-scale or complex projects.

- Measurement Ease: It simplifies the measurement-related complexities in designing and laying bricks, resulting in more rapid and efficient construction.

- Quality: Standardizing measurement ensures quality control across the entire structure.

Gauging Tools

A brick gauge tool, such as a rod or a rule, is typically used to effectively measure the required dimensions. These tools enable accuracy in the laying process, thus ensuring each brick fits perfectly with the next.

Calculating Brick Gauge

Brick gauging involves a simple calculation using the dimension of the brick (plus the mortar joint) and the total length or height of the wall structure. The total number of bricks is then divided by the height or length to give the gauge, providing you with the number of courses needed in your construction.

Challenges of Brick Gauging

- Complexity: Requires meticulous measurement and attention to detail.

- Time-Consuming: Can increase project timelines due to the nature of the process.

- Ability: Needs skilled bricklayers familiar with the gauging process.

Aside From Walls, How Does This Apply To Brick Arches?

Concept of Gauged Brick Arches

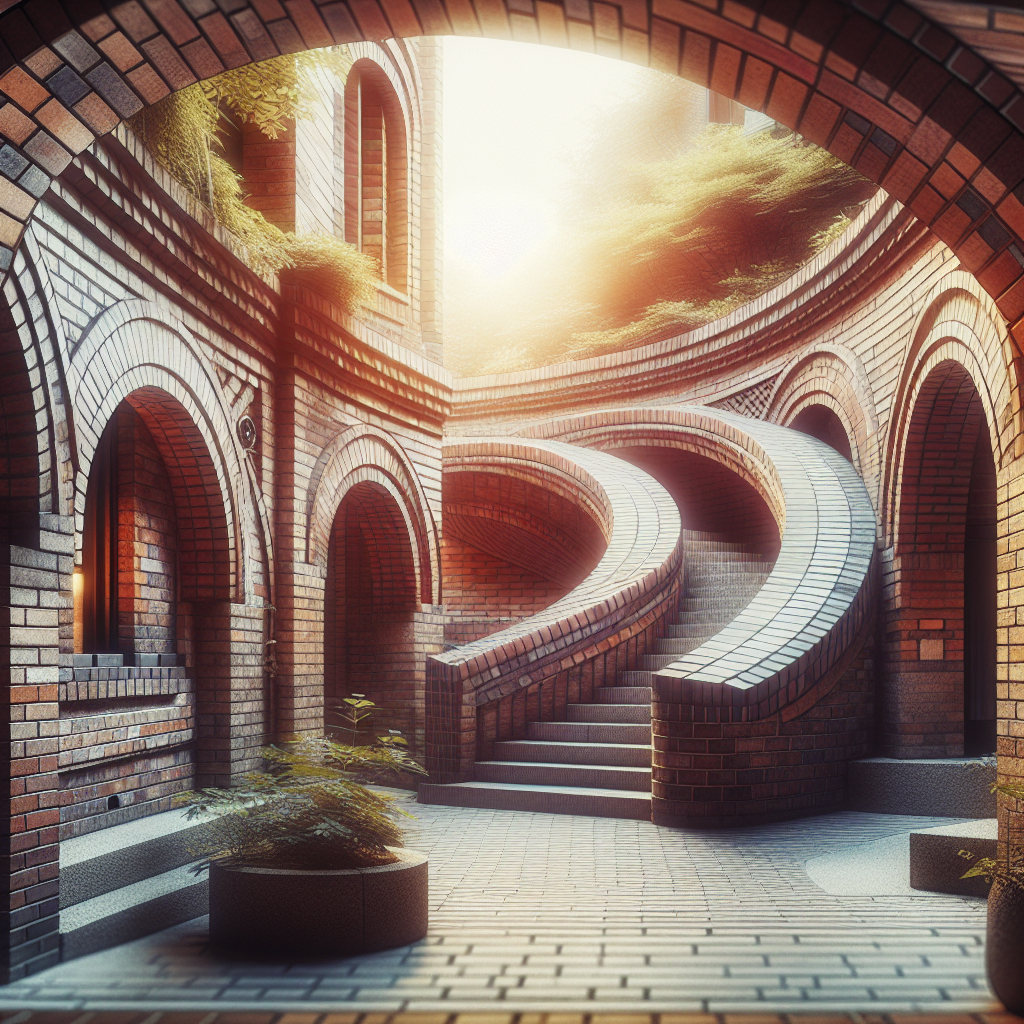

Gauged brick arches are specialized architectural elements where bricks are meticulously cut and shaped to form smooth, precise curves or spans. These arches are often used for both structural and decorative purposes, particularly in historical or high-end construction projects.

The term “gauged” indicates that the bricks are shaped to exact specifications, ensuring a uniform appearance and structural integrity.

Types of Gauged Brick Arches

- Semi-Circular Arches: Formed in a half-circle, commonly used in Roman architecture.

- Segmental Arches: Less than a semi-circle, offering a flatter, more contemporary aesthetic.

- Pointed Arches: Also known as Gothic arches, characterized by their pointed apex.

- Flat Arches: Almost horizontal, providing a subtle curve used in modern designs.

Applications in Construction

- Entrances and Facades: Creating grand, eye-catching entryways that enhance the architectural appeal.

- Windows and Doorways: Adding elegance and historical authenticity to openings in walls.

- Bridges and Overpasses: Utilized in both ancient and modern designs for their strength and aesthetic appeal.

- Interior Design Elements: Used in interior spaces to create distinctive and decorative features.

Materials and Tools Specific to Arch Construction

- Arch Bricks: Specially shaped bricks (often wedge-shaped) to fit the curve of the arch.

- Formwork: Temporary molds or scaffolding used to maintain the shape of the arch until the mortar sets.

- Leveling Tools: Ensures the horizontal alignment of the arch during construction.

- Jointing Tools: For creating smooth and consistent mortar joints that complement the precisely cut bricks.

Steps to Construct Gauged Brick Arches

| Step | Description |

|---|---|

| 1. Design | Determine the shape, size, and radius of the arch, including load calculations. |

| 2. Formwork Setup | Install temporary scaffolding or molds to outline the arch shape. |

| 3. Cutting | Shape each brick precisely to fit into the curved design using specialized saws and grinders. |

| 4. Laying | Position the bricks in the formwork, ensuring each brick fits and aligns perfectly with its neighbors. |

| 5. Mortaring | Apply mortar between the bricks, maintaining uniform joint thickness and strength. |

| 6. Setting | Allow the mortar to cure, ensuring the arch maintains its shape and strength before removing formwork. |

Benefits of Using Gauged Brick Arches

- Architectural Beauty: Adds a high level of detail and craftsmanship to any structure.

- Historical Authenticity: Essential for restoration projects that aim to preserve historical accuracy.

- Structural Integrity: Provides robust and reliable support, distributing weight evenly across the span.

Source

For more detailed guidelines on brick arch construction, explore Britannica.

What is the Center Brick on an Archway?

Introduction to the Key Stone

In the context of gauged brick arches, the center brick plays a critical role in the integrity and aesthetics of the archway. This center brick is known as the “keystone.” The keystone is the topmost brick at the apex of the arch, and it is usually a slightly wedge-shaped, ornamental piece that locks all the other bricks (voussoirs) into place.

Function of the Keystone

- Structural Support: The keystone is vital for distributing weight evenly across the arch, thereby ensuring structural stability.

- Load Transfer: By fitting snugly into the arch’s apex, the keystone helps to direct weight away from the center and down towards the arch ends.

- Aesthetics: Often designed to be decorative, the keystone adds a visual focal point at the top of the arch.

Materials and Forms of Keystones

Keystones can be made from various materials, depending on the architectural style and requirements.

- Materials: Common materials include natural stone, high-quality brick, and sometimes concrete.

- Forms: Keystones can be simple in design or highly ornamental, often featuring carvings or inscriptions.

Examples of Keystone Usage

To better understand the significance of the keystone, here are some practical examples of its application:

- Historical Buildings: In many classical buildings, keystones are elaborately carved with dates, emblems, or other historical symbols.

- Modern Architecture: Even in contemporary structures, keystones may be used for aesthetic purposes, blending modern design with traditional elements.

Steps to Install a Keystone

| Step | Description |

|---|---|

| 1. Design | Planning the arch layout, including the keystone dimensions and placement. |

| 2. Cutting | Precisely cutting the keystone to ensure it fits well into the prepared arch formwork. |

| 3. Positioning | Carefully placing the keystone at the apex of the arch during the laying process. |

| 4. Mortaring | Applying mortar between the keystone and adjacent bricks to secure it firmly. |

| 5. Curing | Allowing the mortar to set and cure fully before removing any supporting formwork. |

Challenges in Installing Keystones

- Precision: Ensuring the keystone fits perfectly within the arch curve requires precision measurement and cutting.

- Alignment: Proper alignment is crucial; any misalignment can compromise the structural integrity of the arch.

- Weight: The keystone must be strong enough to bear the arch load and may require specialized materials for larger constructions.

Conclusion

In conclusion, gauged brickwork is an intricate, labor-intensive masonry technique that yields high-quality, precision-cut bricks.

Its main appeal lies in its uniform, aesthetic finish, making it a popular choice for projects where detail and appearance are critical. This includes applications such as ornamental facades, historical restorations, and architectural elements.

Comprehending the brick gauging system – the method for maintaining consistent brick dimensions, and the gauged brick arches – architectural technique with uniform brick shaping, adds depth to our understanding of the construction sphere.

Keystones, the center brick in an archway, play an important role in both the aesthetic appeal and structural integrity of an archway, symbolizing the capstone of gauged brickwork’s architectural marvel.

Frequently Asked Questions – FAQs

What is gauged brickwork?

Gauged brickwork refers to a specific type of brick masonry where the bricks are meticulously cut and finished to exact dimensions, ensuring a uniform and aesthetic appearance. It is typically used in detailed and decorative projects.

What tools are used in gauged brickwork?

Some of the main tools used in gauged brickwork include high-quality bricks, specialized cutting tools like brick saws and grinders, and gauging tools for ensuring each brick’s precision.

What are the applications of gauged brickwork?

Gauged brickwork is commonly used in ornamental facades, historical restorations, and various architectural elements such as arches, cornices, and decorative panels due to its aesthetic appeal, uniformity, and precision.

What is a brick gauge in construction?

The brick gauge is a process of maintaining consistent dimensions in brick masonry. It determines the number of courses (horizontal layers of bricks) based on a set wall height, lending uniformity and structural strength to the building project.

What are brick arches and their use in construction?

Brick arches, a specialized form of gauged brickwork, are architectural elements crafted through precise cutting and shaping of bricks to form curves or spans. They are strategically used for both structural and decorative purposes in construction projects, particularly in historical or high-end styles.

What is the role of a keystone in an archway?

The keystone is the central brick at the apex of an archway that locks all other bricks in place, thereby ensuring the structural stability and aesthetic completion of the archway. It is crucial for distributing weight evenly across the arch and is often ornamental, serving as a visual focal point.