Introduction to Brick Construction and Cuts

Wondering what bat bricks are and why they matter in construction?

If you’re even slightly curious about building and the science behind it, you’re in the right place!

Ever thought about why a building can stand sturdy, or why some buildings have visually appealing brick pattern?

A lot of it has to do with something called ‘bat bricks’.

You see, construction isn’t all about cement and hammers. It’s also about selecting the right materials and knowing how to use them.

Bat bricks are one of those special tools of the trade.

In this article, we’ll explore what bat bricks are, their dimensions, applications, and how to make or obtain them. We’ll also tap into their various advantages, the environmental impact they offer, and how to choose the right bat bricks for your projects.

Finally, to provide a holistic view, we’ll break down the different types of brick cuts beyond bat bricks.

Let’s get started!

Table of Contents

Understanding Bat Bricks in Construction

Introduction to Bat Bricks

In the construction world, terms can often get confusing, and “bat bricks” is no exception. These specialized bricks have unique applications that make them essential for certain building projects.

Defining Bat Bricks

Bat bricks are specially cut bricks that are typically used to complete a course of bricks. They play a critical role in ensuring the structural integrity and aesthetic continuity of a brick wall.

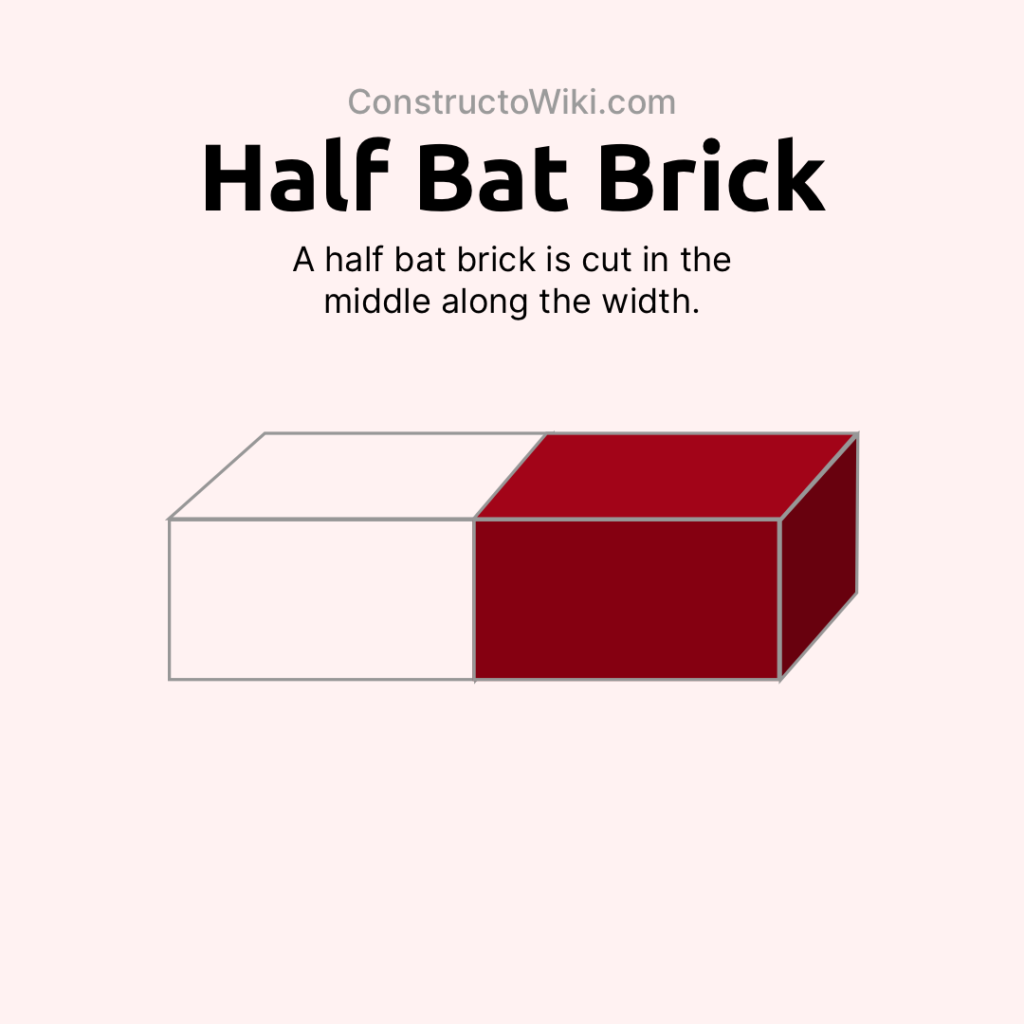

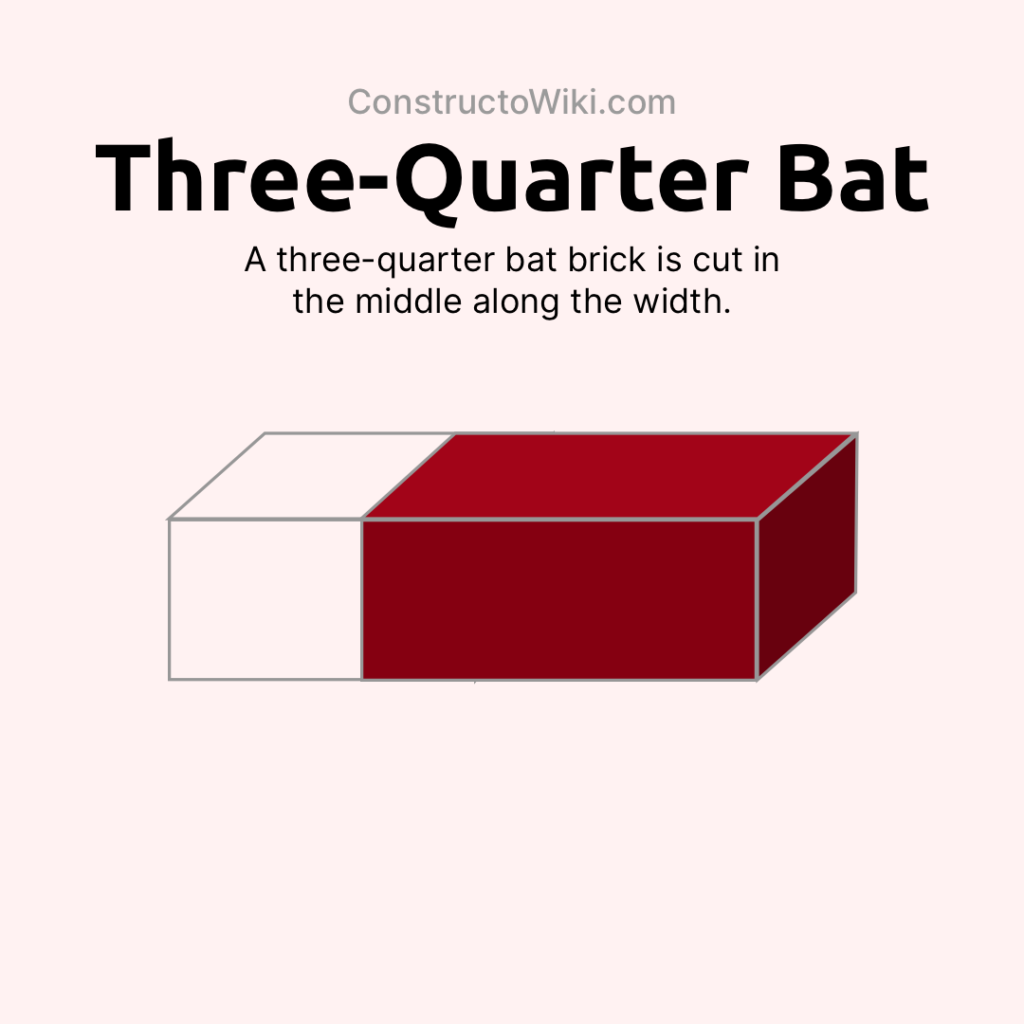

They are called bat bricks when they are cut along the width of the brick.

Dimensions of Bat Bricks

Bat bricks are essentially half or three-quarter bricks. Their specific dimensions are as follows when applied to one of the most common brick types, the Modular brick:

| Type | Length | Width | Height |

|---|---|---|---|

| Half Bat | ~4 inches | 3 5/8 inches | 2 1/4 inches |

| Three-Quarter Bat | ~6 inches | 3 5/8 inches | 2 1/4 inches |

Uses and Applications of Bat Bricks

Bat bricks find their use in several specific scenarios:

- Finishing Corners: Used to finish off the ends of walls to ensure corners are correctly aligned.

- Structural Integrity: Filling gaps left by full bricks ensures that the wall’s load-bearing capacity is maintained.

- Design and Aesthetics: Used to create or continue patterns and designs within brickwork.

Their precise cutting allows for consistent and professional construction results.

How to Make or Obtain Bat Bricks

Bat bricks are often made on-site by cutting full bricks using brick saws or hammers and chisels. They can also be purchased pre-cut for convenience from masonry suppliers.

Tools Required

To create bat bricks on-site, you’ll typically need:

- Brick Saw

- Hammer and Chisel

- Measuring Tape

- Safety Gear (gloves, goggles)

Maximizing the Potentials of Bat Bricks in Construction

The Science Behind Bat Bricks’ Shape

One reason they are called “bats” is due to terminology historically used in the lumber and masonry industry where “bat” has been synonymous with a segment of material.

The shape of bat bricks makes them vital in various construction scenarios. Splitting a full brick into half or three-quarter creates a block that fits perfectly in places where a full brick cannot.

This aids in achieving a seamlessly aligned brickwork and a more stable structure. It allows builders to avoid oversized or undersized brick lengths showing up in a completed work, which can disrupt the pattern and compromise the structural strength.

Key Advantages of Bat Bricks

While the primary uses of bat bricks are mentioned earlier, their advantages go beyond structural and aesthetic benefits:

- Material Conservation: In scenarios where only half or a portion of a brick is required, using bat bricks helps in reducing the unnecessary waste of material.

- Faster Construction: Ready-to-use bat bricks often speed up the bricklaying process.

- Cost-effective: As they utilize potentially leftover materials, bat bricks can contribute to more cost-efficient construction.

The Environmental Impact of Bat Bricks

Bat bricks, in a roundabout way, lessen the environmental impact of construction because of their inherent nature in promoting resource conservation.

By minimizing brick wastage through their strategic use in construction, fewer materials are utilized, which results in reduced energy consumption for brick production and lower associated carbon emissions.

Choosing the Right Bat Bricks

Choosing the right bat bricks can either make or break the success of a construction project. It’s essential to pick bat bricks with the same compressive strength, moisture expansion, and color as the full bricks being used in the project. This ensures cohesiveness in the finished structure, both visually and structurally.

Steps to Choose the Right Bat Bricks:

Here’s a simple guide to ensure you’re making the right choice:

- Identify the type of full bricks used in the project.

- Match the physical and mechanical properties of the bat bricks to the full bricks.

- Make sure the bat bricks are of the highest quality to ensure durability and longevity.

For more help in making your choice, you can check out the useful guide provided by Wienerberger, a leading provider of building material solutions.

Understanding Other Types of Brick Cuts

Introduction to Brick Cuts

In masonry, different types of cuts are made to bricks to achieve specific structural and aesthetic designs. Alongside bat bricks, several other brick cuts are commonly used in construction projects.

Different Types of Brick Cuts

Here are the various types of brick cuts beyond bat bricks:

Queen Closer

A queen closer is a brick cut along its length into two equal pieces. It is typically used next to a corner to achieve a symmetrical end.

| Type | Length | Width | Height |

|---|---|---|---|

| Queen Closer | 8 inches | ~2 inches | 2 1/4 inches |

King Closer

A king closer is a brick cut diagonally along its length to create a triangular shape. It’s used to create true or half-bonded corners.

| Type | Length | Width | Height |

|---|---|---|---|

| King Closer | Varies | Varies | 2 1/4 inches |

Three-Quarter Width Brick

This brick is cut to three quarters of its width. Unlike the three-quarter bat, which is cut along the width, the three-quarter width is cut along the length.

| Type | Length | Width | Height |

|---|---|---|---|

| Three-Quarter Length Brick | 8 inches | ~3 inches | 2 1/4 inches |

Motor Joint Brick

This type involves creating recesses along the horizontal or vertical joints between bricks. It helps in enhancing the adhesion of the mortar in the joints.

Use and Benefits of Different Brick Cuts

Different brick cuts serve various purposes and offer multiple benefits:

- Enhanced Aesthetics: Different cuts allow for versatile and intricate designs in brickwork, increasing the visual appeal of structures.

- Structural Benefits: Specific cuts, like queen closers and king closers, are essential for achieving proper alignment and load distribution in the walls.

- Custom Fit: Custom cuts ensure precise fitting of bricks into complex wall designs, which enhances the overall integrity and longevity of the construction.

Choosing the Right Brick Cuts for Your Project

To achieve the best results in your construction projects, it’s essential to select the appropriate brick cuts:

Steps to Choose the Right Brick Cuts:

- Identify the architectural requirements of your project.

- Consult with a structural engineer or a mason for expert advice on suitable cuts.

- Ensure the brick cuts match the physical and aesthetic features of the full bricks being used.

Wrapping Up Bat Bricks’ Role in Construction

In all elements of construction, detail matters, and bat bricks exemplify this principle. Used for filling gaps, finalizing corners, and continuing wall patterns, bat bricks uphold both the structural integrity and aesthetic cohesion of a wall.

Their appropriate utilization not only boosts construction efficiency, but also promotes material conservation – contributing to less environmental footprint.

Aside from bat bricks, other brick cuts like Queen Closer, King Closer, and Three-Quarter Length Brick also plays significant roles in masonry – each with their unique dimension and applications.

Key to successful bricklaying projects, however, is the careful selection of brick types and cuts that meet the physical, mechanical, and aesthetic requirements of a structure.

Frequently Asked Questions – FAQs

What are bat bricks used for in construction?

Bat bricks are used for filling gaps, completing corners, and continuing wall patterns thus contributing to the structural stability and aesthetic cohesion of the building.

How do bat bricks contribute to environmental conservation?

By making optimal use of leftover materials, bat bricks reduce wastage. This in turn results in lower energy consumption used in brick making and indirectly leads to reduced carbon emissions.

What other types of brick cuts are used in construction?

Other common types of brick cuts used in construction include Queen Closer, King Closer, Three-Quarter Length Brick, and Motor Joint Brick. Each cut has unique dimensions and hence different applications.

What are the steps to choose the right bat bricks?

Choosing the right bat bricks involves matching the physical and mechanical properties of the bat bricks to the full bricks used in the project and ensuring the highest quality for durability and longevity.