Delving into the Intricacies of Construction and Infrastructure Set-Up

Ever wonder what keeps our skyscrapers standing tall?

Or how cables are perfectly aligned to deliver uninterrupted cable service?

Behind each building and cable network, countless engineering parameters and calculations make these everyday miracles possible. One such critical facet in the construction industry is the concept of ‘side wall bearing pressure’.

Equally essential in network setups is the concept of ‘cable pulling force’. Let’s walk you through these intriguing concepts that form the foundation of the built environment we inhabit.

But first, a question. Do you know the common factors connecting side wall bearing pressure and cable pulling force?

Keep this question in the back of your mind as you read on.

Table of Contents

Let’s Learn About Side Wall Bearing Pressure

The Core of Side Wall Bearing Pressure

The term ‘side wall bearing pressure’ might be new for many, but if you are linked with the construction industry, it’s a term you should be familiar with.

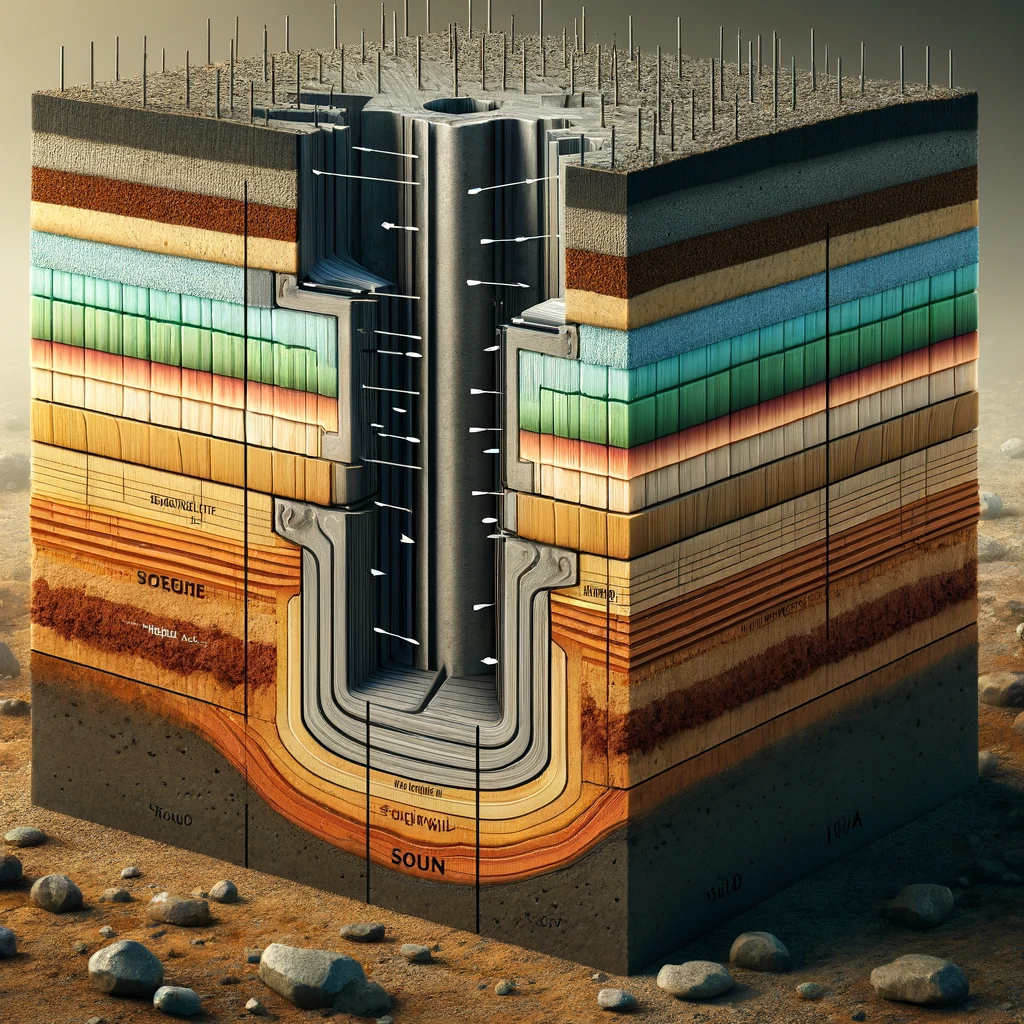

Essentially, side wall bearing pressure refers to the pressure exerted by a structure on the surrounding soil or substrata.

Calculating Side Wall Bearing Pressure

The calculation of side wall bearing pressure involves a myriad of factors. Some of the primary considerations include the weight of the structure, the type of soil in the ground, and the depth of the foundation.

Engineers use these variables to determine how much pressure a structure will exert on the ground at its sides.

Imperative Components

- Structure Weight: This is determined using blueprints, CAD designs, and sometimes physical measurements. The weight of the structure contributes directly to the side wall bearing pressure.

- Soil Type: Different soil types can withstand different pressures. As such, the soil composition of a site plays a significant role in determining the acceptable side wall bearing pressure.

- Foundation Depth: The depth of a structure’s foundation can influence the distribution of the building’s weight. Deeper foundations can generally sustain higher pressure.

A Glimpse at the Importance of Side Wall Bearing Pressure

The importance of understanding and properly calculating side wall bearing pressure cannot be overstated. It directly impacts a structure’s stability and sustainability. Here are a few key reasons why it’s so central to construction planning:

Structural Stability

The pressure a structure exerts on the ground must not surpass the soil’s capacity. If it does, the structure may sink, tilt, or even collapse, as the soil may not be able to adequately support the structure’s weight. This makes accurate side wall bearing pressure calculations paramount to ensuring a building’s stability.

Sustainability

Maintaining equilibrium with surrounding environments is a core principle of sustainable engineering. The calculations of side wall bearing pressure help to ensure that structures are in harmony with their surroundings, minimizing their negative environmental impact.

| Quick Insights | |

| Term | Side Wall Bearing Pressure |

| Definition | Pressure exerted by a structure on the surrounding soil |

| Components | Structure Weight, Soil Type, Foundation Depth |

| Key Importance | Structural Stability, Sustainability |

Maximum Side Wall Bearing Pressure

Mastering Max Side Wall Bearing Pressure

Often in discussions of side wall bearing pressure, you’ll hear references to the ‘maximum’ side wall bearing pressure.

So, what does ‘maximum’ mean in this context?

Simply put, the maximum side wall bearing pressure is the highest amount of pressure that the soil or substrata can withstand from a structure without detrimental effects. Exceeding this maximum can lead to instability or even structural failure.

How to Determine the Maximum Side Wall Bearing Pressure

Determining the maximum side wall bearing pressure isn’t a guess-work. It involves careful data collection and, often, laboratory testing.

Engineers use soil analysis and the aforementioned variables (structure weight, soil type, and foundation depth), along with factors like soil cohesion and internal friction angle to pinpoint the highest pressure that the ground at site can safely bear.

Necessary Measurements

- Soil Cohesion: This is the inherent ability of soil particles to stick together. High cohesion values correlate with a higher maximum side wall bearing pressure.

- Internal Friction Angle: This measures the resistance of the soil to shearing or sliding. A larger internal friction angle equates to a higher maximum side wall bearing pressure.

Consequences of Exceeding Maximum Side Wall Bearing Pressure

Structural Complications

Going beyond the set maximum side wall bearing pressure is flirting with disaster. If the pressure applied by a structure exceeds the soil’s ability to resist, one possible outcome might be unexpected settlement or sinking of the structure, leading to serious structural damage or even crew safety hazards.

Environmental Ramifications

Exceeding the maximum side wall bearing pressure not only risks the structure, but the environment as well. It can prompt soil displacement, erosion, and disturbance of local habitats, leading to implementation of costly mitigation techniques to restore the eco-balance.

| Crucial Points to Remember | |

| Term | Maximum Side Wall Bearing Pressure |

| Definition | Highest pressure that the soil can safely bear from a structure |

| Key Measurements | Soil Cohesion, Internal Friction Angle |

| Risks of Exceeding | Structural Damage, Environmental Disturbance |

Switching Gears To Cable Pulling Force

The Fundamentals of Cable Pulling Force

In the sphere of electrical installations and network configurations, cable pulling force emerges as a crucial concept to grasp.

Essentially, cable pulling force is the measure of tension applied onto a cable as it is hauled through a conduit or duct. Getting this right is essential to prevent causing strain or damage to the cable.

Factors Influencing Cable Pulling Force

Several dynamic variables play into the calculation of safe cable pulling force. Of these, the most critical ones include the cable weight, conduit path, conduit material, and cable to duct surface friction. Professionals use these inputs to ensure optimal, damage-free cable pulls.

Key Factors

- Cable weight: Depending on the size and material of the cable, its weight can create pulling resistance and hence directly impacts the calculation of pulling force.

- Conduit path: The conduit’s route impacts the pulling force required. More bends and turns mean more friction and thus, higher pulling force.

- Conduit material: Different materials may cause varying levels of friction. Rough surfaces or sharp bends can significantly increase force needed.

- Cable to duct surface friction: Depending on the cable sheathing material and duct texture, this friction can significantly influence the pulling force calculation.

So, What is Safe Cable Pulling Force?

While there are various factors at play, a broadly imbibed rule among field technicians is not to exceed pulling tension that would lead to 5% elongation of the cable.

This is also known as the Maximum Allowable Tensile Load (MATL). In a nutshell, the load should not be such that it stretches the cable and alters its length.

Calculating Safe Cable Pulling Force

The formula for calculating Maximum Allowable Tensile Load (MATL) is:

MATL = Cable Weight x Distance x 5%

This formula is without duct friction. If the duct friction is to be considered, then the friction coefficient should be added to the calculation.

| Important Cable Pulling Force Aspects | |

| Term | Safe Cable Pulling Force |

| Definition | Measure of tension that ensures damage-free cable pull |

| Key Factors | Cable Weight, Conduit Path, Conduit Material, Cable-Duct Surface Friction |

| Safe Force Indicator | 5% Cable Elongation (MATL) |

Effect of Exceeding Safe Cable Pulling Force

Cascade of Cable Damages

Excessive pulling force can result in various cable damages. An over-stretched cable can experience reduction in bandwidth carrying capacity, have its inner conductors jumbled, or its insulation layer may get distorted – all impacting overall performance and life expectancy of the cable.

Hazardous Working Conditions

Exceeding safe cable pulling force not only harms the cable but also increases the risk of job site accidents. The high tension can make the cable snap and lash out, presenting potential hazards to personnel or surrounding equipment.

Preventive Measures

To prevent the mishaps resulting from excessive cable pulling force, proper planning of cable installation path, use of appropriate tools and machinery, and meticulous calculation of MATL should be undertaken. Also, care should always be taken to account for the right friction coefficient depending on cable and conduit material and conduit path.

| Risks of Excessive Cable Pulling Force | |

| Potential Damage | Cable Damage, Reduced Cable Performance, Risk to personnel safety |

| Preventive Planning | Calculate MATL accurately, Optimize installation path, Use proper cable pulling tools and equipment |

the Effects of Ambient Temperature on Maximum Pulling Tension

Impact of Temperature on Cable Pulling

Temperature, an often overlooked factor, plays a significant role in determining the maximum pulling tension for a cable.

The physical properties of a cable alter with changes in temperature, affecting the maximum pulling tension. High temperatures can soften the jacket and insulation material, making the cable more prone to stretching and damage. On the contrary, low temperatures often make cables stiff and inflexible, increasing the strain during the pulling process.

How to account for Temperature

To account for the impact of temperature, installation manuals often include a correction factor table. These tables provide a factor that needs to be multiplied with the Maximum Allowable Tensile Load (MATL) under normal conditions. Professionals need to take this into account to keep their cable pulling force within the safe range in different temperatures.

Nuances in Different Types of Cables

- Fiber Optic Cables: Fiber optic cables are extremely sensitive to temperature fluctuations. Even a slight increase in temperature can cause the fiber optic cable to stretch and become vulnerable to breakage. It’s crucial to store and install these cables within the manufacturer specified temperature range.

- Copper Cables: Copper cables exhibit more tolerance to temperature variations. However, high temperatures may cause the copper to expand, increasing the internal stresses and reducing their tensile strength.

| Influence of Temperature on Cable Pulling | |

| Role of Temperature | Alters physical properties of cable, affecting the pulling tension. |

| How to Account for It | Use correction factors in installation manuals to adjust MATL. |

| Effects on Different Cables | Fiber Optic Cables are very sensitive; Copper Cables are more tolerant but still affected. |

Tools and Equipment to Maintain Safe Pulling Tension

Critical Tools for Cable Pulling

Utilizing appropriate tools and equipment is invaluable for maintaining safe cable pulling tensions. These tools not only streamline the cable installation process but also ensure the safety and integrity of both the cable and the personnel involved in the project.

What Tools Are We Talking About?

- Cable Pullers: These machines provide the force needed for cable pulling, ensuring a steady and controlled pull. They feature adjustments for pulling speed and force, enabling installers to stay within the MATL.

- Cable Lubricants: These reduce the friction between the cable and the conduit, reducing the pulling force and thereby, the pulling tension on the cable. It’s crucial to use the right lubricant for the type of cable and conduit used.

- Rope Tensiometers: These devices measure the tension in the pulling rope, helping to ensure that the maximum pulling tension is not exceeded.

Selection and Usage Considerations

It’s important to select the right tools for the job and to use them properly. Misused or inappropriate equipment can lead to a multitude of issues including, but not limited to, exceeding the maximum pulling tension. Always follow manufacturer’s instructions regarding the operation and maintenance of these tools.

| Significance of Tools in Safe Cable Pulling | |

| Tools Importance | Facilitates controlled pulling, Ensures safety of cable and crew. |

| Key Tools | Cable Pullers, Cable Lubricants, Rope Tensiometers. |

| Tool Usage Considerations | Selection of right tools, Adherence to manufacturer’s instructions. |

Wrapping Up the Elements of Side Wall Bearing Pressure

By now, it should be clear that side wall bearing pressure is an aspect of construction engineering that cannot be ignored.

This pressure—a blend of the structure’s weight, the properties of the soil, and the depth of the foundation—plays an integral role in determining a building’s interaction with the earth around it.

It’s not just about numbers on a page; these calculations directly influence both the stability and sustainability of our structures – they prevent our buildings from sinking, and help them exist harmoniously with their environment.

It’s a fascinating field, blending science, design, and practical considerations in a way that impacts us all. So, remember, the next time you’re looking at a skyscraper or any piece of infrastructure, there’s a whole world of calculations and thought keeping it standing–and one of the key components is undoubtedly side wall bearing pressure.