Understanding Split-Phase Electric Systems

Curious about what a split-phase system means in the world of construction? Or ever wondered why your home appliances draw power without overloading?

The answer lies in understanding “split-phase”, a common, yet often overlooked term in electrical construction.

In this post, we will explore what split-phase means, how it applies to your day-to-day routines, and why it’s essential in residential construction in North America. We’ll also reveal how it contributes to the safe and balanced distribution of power across various appliances in your home.

By the end, you’ll not only understand what makes up a split-phase system, but also learn key maintenance tips that can help keep your home’s electrical system running smoothly.

Let’s get started.

Table of Contents

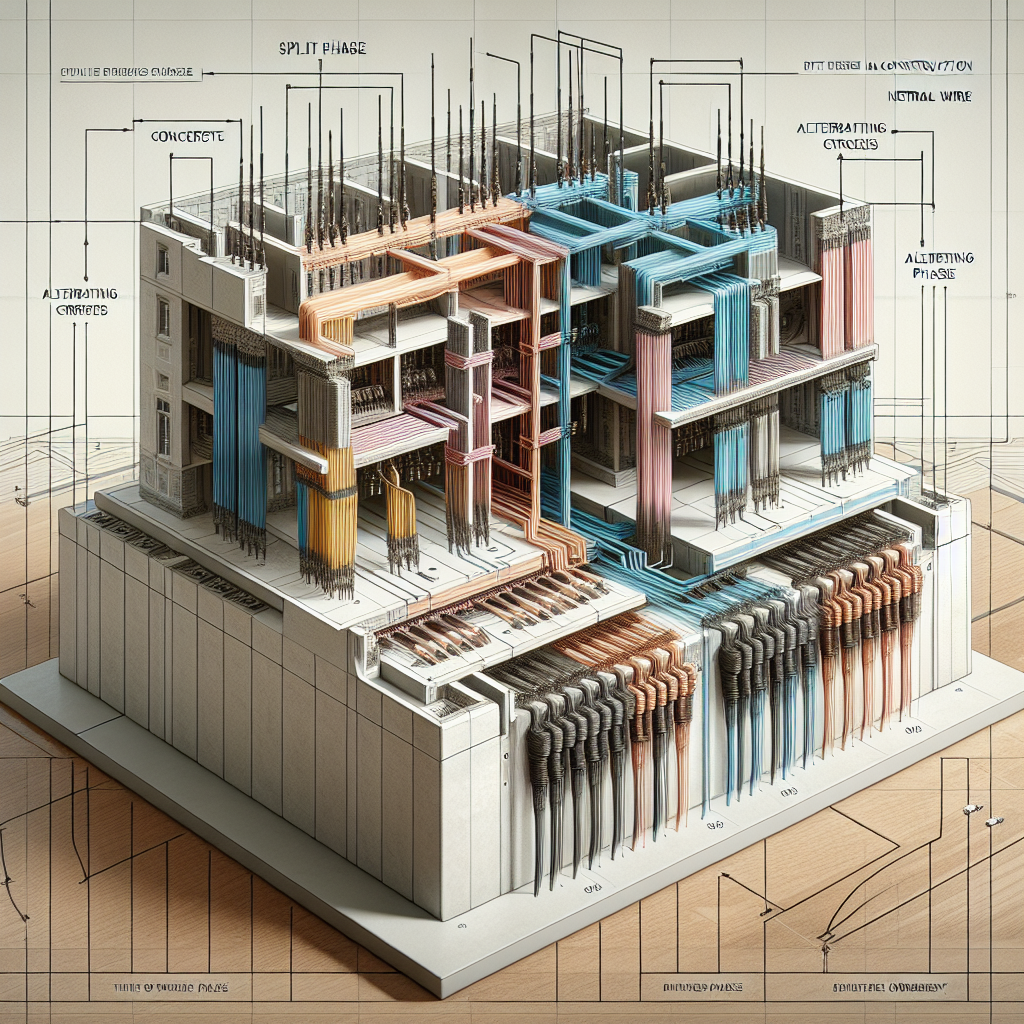

The Meaning of Split-Phase in Construction

Definition of Split-Phase

Split-phase is a type of single-phase electrical distribution system typically used for residential electricity supply.

This method involves two wires carrying inverted voltages, adding a third wire that is neutral, resulting in two circuits with voltage peaks at different times. This means the load sharing between these two circuits is balanced, reducing the chances of overloading one.

Key Elements of Split-Phase

Now that we’ve simplified the definition of split-phase, let’s break down the crucial elements involved in this electrical construction concept.

- Inverted Voltages: This refers to two waves of the same frequency that are 180° out of phase. In a split-phase system, these voltages are carried along two wires.

- Neutral Wire: The function of the neutral wire is to carry any unbalanced load between the two other wires. It acts as a return path for the current.

- Load Balancing: One of the primary advantages of a split-phase system is its ability to balance loads between the two circuits, reducing the risk of overload.

Usage of Split-Phase

Knowing the key elements and definition of split-phase is all well and good, but how does it apply to construction? Let’s explore this.

In North American home constructions, split-phase electrical system is the standard. It’s used because it creates two separate 120V circuits, perfect for standard household appliances, while also allowing for a 240V circuit for larger appliances like air conditioners and electric heaters.

Maintaining a Split-Phase System

Maintenance of your split-phase system is just as important as understanding the basics. Notably, it’s crucial to ensure that the system is balanced. This means that the loads connected to the two 120V circuits are roughly equivalent.

Key Tips to Maintain Split-Phase System

- Regular Inspection: Overloads can occur due to weather, age, or circuit additions. Regular inspection is recommended to detect and rectify imbalances early.

- Load Balancing: Minimize the risk of overloads by ensuring an even distribution of loads across the circuits.

- Professional Consultation: Any serious concerns or uncertainties regarding your split-phase system should always be dealt with by a professional electrician.

Switching To the 240V Single-Phase

Introduction to 240V Single-Phase

In the world of electrical wiring, it’s common to come across a seemingly complex term: 240V single-phase. Much like the split-phase system we have previously discussed, understanding the meaning and application of 240V single-phase can be key in the construction field.

Defining 240V Single-Phase

A 240V single-phase system is another subtype of single-phase electrical distribution, widely used in both residential and commercial settings. This system uses a single, two-wire conductor and a ground.

The 240V refers to the voltage of the power that’s being distributed, which is double the standard residential voltage of 120V in North America.

Key Components of 240V Single-Phase

While diving into this system, there are certain key elements to focus on.

- Two-Wire Conductor: The system works with a single conductor that has two wires. This conductor manages the flow of electricity.

- Ground: The ground, or earth, offers an alternative pathway for the current to decrease the risks related with electrical faults.

- Voltage: In this system, the voltage level is 240V, which is higher than the typical 120V, making it appropriate for larger types of equipment.

Gearing 240V Single-Phase Towards Practical Usage

When we talk about the practical applications of 240V single-phase, they are largely similar to the split-phase system. This system is primarily designed to power larger appliances, which require more power than standard 120V outlets can provide.

Large appliances, such as cloth dryers, ovens, and central air-conditioning systems, commonly use 240V single-phase power. This setup is also found in commercial applications where higher voltage is needed.

240V Single-Phase Care and Maintenance

Like any electrical system, regular maintenance is especially critical for the 240V single-phase system. Safety and efficiency are key, and keen attention needs to be given to these principles.

Key Tips to Maintain 240V Single-Phase System

- Safety Precautions: Working with higher voltages increases the risk of electrical shock, so it’s more important than ever to follow safety guidelines strictly.

- Regular Inspection: Implementing a regular inspection regimen helps to identify potential issues before they become large problems. This includes appearing for any wiring damage, obstructions, or faulty appliances.

- Professional Intervention: If there’s any doubt about the system’s functionality, a professional electrician’s opinion must always be sought. It ensures safety and correct intervention.

Split-Phase Versus Two-Phase: A Comparison

Understanding Two-Phase Systems

If you’re contemplating the similarities and differences of split-phase and two-phase systems, it’s vital to begin by defining a two-phase system. A two-phase system is a type of polyphase system often used in high power applications. This system includes two alternating currents (AC) carried on separate wires, each 90° out of phase with each other.

The Difference between Split-Phase and Two-Phase Systems

While both split-phase and two-phase electrical systems are used to distribute electrical power, they are not the same thing. The primary difference lies in the phase displacement of their ACs and their uses. In a split-phase system, the voltages are 180° out of phase and typically used in residential settings. In contrast, in a two-phase system, the ACs are 90° out of phase and generally suited for high powered applications.

Key Differences Considered

- Phase Displacement: Split-phase features AC voltages 180° out of phase, while two-phase showcases voltages 90° out of phase.

- Usage: Split-phase is predominantly found in residential settings to run a variety of household appliances. Two-phase, however, is usually employed in industrial applications for high-powered equipment.

- Complexity: Though both these systems are efficient, two-phase systems tend to be more complex due to the higher phase displacement and power implications.

The Merits of Using Split-Phase or Two-Phase

Choosing the Right System

When it comes to choosing between a split-phase and a two-phase system, the primary consideration should be your specific needs and technical capabilities. Understanding the underlying principles of each system and their respective merits can help guide an informed decision.

Why Choose Split-Phase?

- Flexibility: Split-phase electrical systems offer the flexibility of providing two separate 120V circuits and a 240V circuit from a single AC power source. This makes it well-suited to a variety of residential applications.

- Load Balancing: As aforementioned, split-phase systems do an excellent job of balancing loads, reducing chances of overloaded circuits.

- Simplicity: Despite some technicalities, split-phase systems are generally less complex, making them more accessible to the average homeowner or handyman.

Why Opt for Two-Phase?

- High Power Applications: Due to the unique setup of a two-phase system, it’s ideal for high-power applications and is therefore found in industries and businesses with significant electricity demands.

- Efficiency: Two-phase systems are remarkably efficient, minimizing power loss and keeping operations smoothly running.

- Voltage Regulation: Compared to single-phase systems, two-phase systems often express improved voltage regulation, vital in scenarios demanding a steady power supply.

Exploring the Concept of Split-Phase Charging

Defining Split-Phase Charging

Split-phase charging is an integral part of split-phase electrical systems, which we have already covered. However, the charging aspect is a little more specific. It refers to how power is delivered to devices. In split-phase systems, electrical energy is transferred via two voltage circuits that peak at different times, providing a more efficient mode of power delivery.

Understanding the Basics of Split-Phase Charging

- Charging Cycles: Split-phase charging cycles include two voltage peaks that occur at distinct times. This characteristic influences how effectively appliances can draw power.

- Load Distribution: The split-phase system is known for its balanced load sharing. This balance applies equally to split-phase charging. The system ensures that devices are recharged evenly without overload.

- Demand Efficiency: Thanks to its dual-phase design, split-phase charging allows devices to draw energy when they need it most, leading to improved demand efficiency.

Applications of Split-Phase Charging

While split-phase systems are generally associated with household uses, split-phase charging has broader applications. It is often used in industrial environments, where equipment requires a high power load and robust charging solutions.

This charging method is also crucial in the context of electric vehicle (EV) charging stations. Considering the need for quick, efficient, and continuous charging, split-phase charging proves beneficial in mitigating exhaustive loads on a single phase.

Ensuring Efficient Split-Phase Charging

Efficiency is the cornerstone of split-phase technology, especially when it comes to charging. Just as with maintaining the split-phase system itself, the charging process also needs careful attention to maintain efficiency.

Guidelines for Efficient Split-Phase Charging

- Load Balance: Ensuring that devices using the charging infrastructure do not overload one of the phases is key to maintaining the system’s operability.

- Periodic Checks: Regular assessments of the system can help detect possible inefficiencies at an early stage, avoiding disruption and potential damages.

- Expert Consultation: Particularly in industrial applications, consulting with a professional can provide invaluable advice for optimizing the system’s efficiency.

Navigating Split-Phase Charging in EV Stations

Adopting Split-Phase Charging in EV Stations

With the widespread growth of electric vehicles, the need for efficient charging infrastructure is equally ballooning. The adoption of split-phase charging in EV stations represents one of the strategies deployed to meet this need.

The Key Aspect: Charging Rate

The charging rate determines how quickly an electric vehicle can be recharged. With split-phase charging, 240V can be achieved, which doubles the rate of standard 120V outlets. This accelerates the charging process, saving users’ time and improving the general EV charging experience.

Underlining Implications

- Higher Power Supply: Split-phase charging at EV stations offers an increased power supply, which aids in shortening the charging duration.

- Efficient Power Traction: Given the load balancing feature of the split-phase system, the charging infrastructure can handle multiple vehicles simultaneously without overloading the system.

- Voltage Compatibility: The enhanced supply voltage aligns better with most EV charging requirements, especially for level 2 chargers that require 240V.

Challenges with Split-Phase Charging for EVs

While split-phase charging offers significant advantages, the system also comes with some challenges, especially in the context of EV stations. One common issue is that many public and private spaces where charging stations are located do not have the necessary 240V outlets.

Addressing Crucial Challenges

- Infrastructure Upgrade: To enable split-phase charging at certain locations, electrical infrastructure must often be upgraded or modified, which can be costly.

- Regulatory Compliance: Depending on the jurisdiction, significant upgrades to electrical infrastructure may require permits or additional regulatory compliance.

- Rethinking Strategies: Given these constraints, some locations may need to rethink their charging infrastructure strategies to accommodate the split-phase system.

Cracking the Code: A Summary of Split-Phase in Electrical Construction

Undeniably, the concept of split-phase provides a significant understanding to anyone exploring the world of electrical construction. Simplified, it’s a type of single-phase electrical distribution system quintessential to residential electricity supply. It maintains an even keel by balancing loads between two circuits, reducing the risk of overloads.

Diving deeper, its key elements like inverted voltages, the neutral wire’s functionality, and the aspect of load balancing set the foundation for this technical term. Furthermore, witnessing its practical usage, especially in North American home constructions, elucidates its prominence—demonstrating its versatility by offering both standard and heavy-duty power circuits, perfectly adjusted to the demands of our everyday appliances.

Lastly, the importance of maintaining such a system cannot be overstated, factors like regular inspection, proper load balancing, and professional consultations ensure the smooth functioning of your system, all while prolonging its overall lifespan. So, armed with this concise breakdown of split-phase and its essence in construction, you’re no longer just a bystander but an informed participant in the fascinating world of electrical construction.