Introduction To Masonry Scaffolding

Ever wondered about the “behind the scenes” structures in the construction world?

Masonry scaffolding is essential for any construction project, providing necessary support for workers and their materials.

In this comprehensive guide, we’ll cover various types of scaffolding, its components, safety measures to observe, and its benefits. Additionally, we’ll touch on some real-world examples and offer tips on selecting the right scaffold for your project.

Do you know masonry scaffolding isn’t one-size-fits-all? We all see scaffoldings around, but it’s fascinating how they adapt to fit diverse construction needs.

Let’s get started and understand the many faces of this construction marvel.

Table of Contents

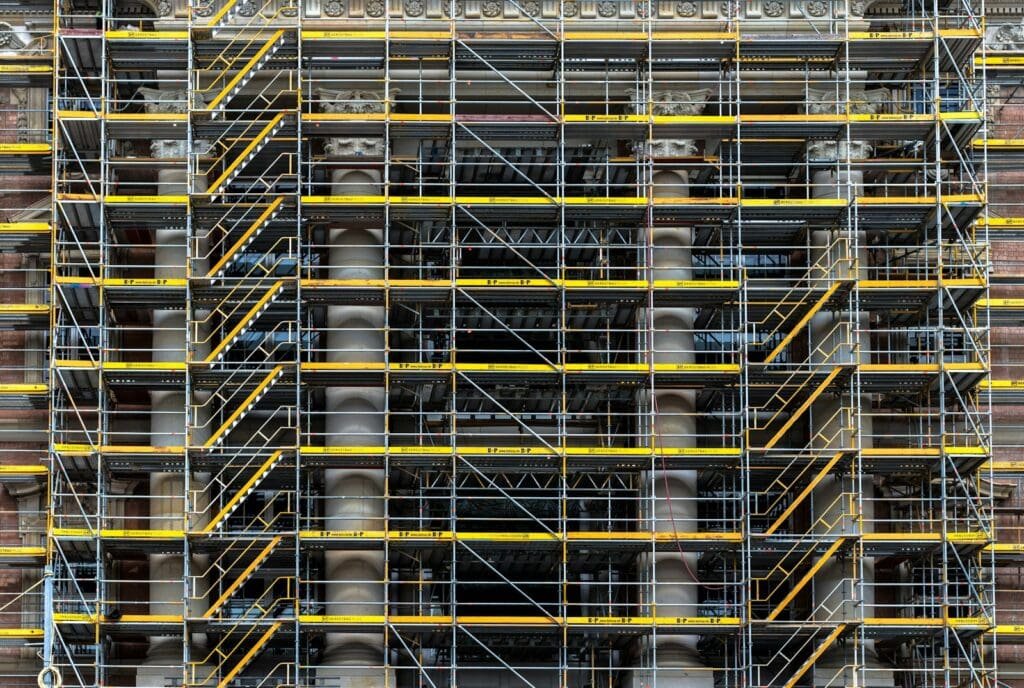

Understanding Masonry Scaffolding

Definition of Masonry Scaffolding

Masonry scaffolding is a temporary structure used in construction to support workers and materials while they build or repair masonry structures like buildings, walls, and other large constructions.

Main Components of Masonry Scaffolding

- Steel or Aluminum Tubes: These are the primary vertical and horizontal supports making up the scaffolding framework.

- Planks or Platforms: The flat surfaces where workers stand and place their materials.

- Base Plates: They provide stability to the scaffold by distributing the load onto a solid surface.

- Braces: These diagonal supports help maintain the structure’s rigidity and integrity.

Types of Masonry Scaffolding

Single Scaffolding

- Single Frame: Consists of a single frame set next to the wall for support.

- Usage: Commonly used for brick masonry work.

Double Scaffolding

- Double Frame: Features two rows of scaffolding for added strength.

- Usage: Ideal for stone masonry work where wall support is minimal.

Needle Scaffolding

- Outrigger Support: Uses needles (cantilever beams) to support scaffolding in spaces where ground structures aren’t feasible.

- Usage: Typically used for high-rise buildings and narrow spaces.

Safety Measures in Masonry Scaffolding

To ensure safe and effective use of masonry scaffolding, adhere to these guidelines:

- Stable Ground: Always set up on a level, stable surface.

- Proper Assembly: Ensure all connections are secure and components are in good condition.

- Weight Limits: Do not exceed recommended weight limits for each scaffold type.

- Regular Inspections: Conduct inspections before use and after any significant weather events or changes in usage.

- Personal Protective Equipment (PPE): Workers should wear helmets, harnesses, and non-slip footwear.

Benefits of Masonry Scaffolding

- Stability: Provides a sturdy base for workers and materials.

- Adaptability: Can be configured for various construction projects and space constraints.

- Efficiency: Facilitates quicker and safer masonry work.

Examples of Masonry Scaffolding in Use

- Residential Building Construction: Used for bricklaying, painting, and repair work.

- Commercial Projects: Employed in constructing office buildings and commercial spaces, particularly during the initial building phase.

- Bridge Construction: Used to provide access and support for workers during the masonry aspects of bridge building.

What Are Three Types of Scaffolds?

1. Supported Scaffolding

- Description: Supported scaffolds are built from the ground up with one or more platforms supported by rigid, load-bearing members such as poles, legs, frames, and outriggers.

- Advantages: Highly stable and can support higher loads, adaptable for various heights and project requirements.

- Common Uses: Widely used in building construction, maintenance of high-rise buildings, and other scenarios where a sturdy, elevated workspace is required.

2. Suspended Scaffolding

- Description: Suspended scaffolds have platforms suspended by ropes or other non-rigid means from an overhead structure. They can be raised and lowered to reach different work areas.

- Advantages: Allows for flexible movement up and down the structure, ideal for tasks that require access to various elevation levels such as window washing or painting tall buildings.

- Common Uses: High-rise window cleaning, exterior painting, and repair work on tall buildings.

3. Rolling Scaffolding

- Description: Rolling scaffolds are mobile scaffolds mounted on casters or wheels, allowing easy movement across different areas of the construction site.

- Advantages: Offers excellent flexibility and mobility, reducing the need for constant assembly and disassembly when moving to new locations.

- Common Uses: Ideal for projects requiring frequent relocation like interior plastering, electrical work, and painting large rooms or halls.

Types of Scaffolding for Brickwork

Brick Veneer Scaffolding

Brick veneer scaffolding is designed specifically to handle the complexities of brick veneer construction. This involves a single layer of bricks attached to the exterior of a building, providing an aesthetic finish.

- Single Row Setup: Usually incorporates a single row of scaffolding close to the structure for easier access to the brick veneer.

- Specialized Bracing: Often includes additional bracing to handle the specific load and stability requirements of laying brick veneers.

Steel Scaffolding for Heavy Brickwork

Steel scaffolding is another popular choice for brick masonry, especially for more massive and heavy-duty construction projects.

- Strength: Offers unparalleled strength and can support significant weights, making it suitable for extensive brick masonry work.

- Durability: Resistant to wear and tear, ensuring a longer lifespan compared to wooden scaffolding.

Modular Scaffolding

Modular scaffolding systems involve the assembly of prefabricated components. This type is often used when working on projects with unique requirements and varying heights.

- Pre-assembled Components: Makes it easy to assemble quickly on-site, saving time and labor costs.

- Customizable Heights: Can be adjusted to different heights as needed, offering greater flexibility.

Kwikstage Scaffolding

Kwikstage scaffolding is a widely-used scaffolding technique, especially in countries like the UK and Australia. This system is modular, making it suitable for various types of masonry work, including brickwork.

- Versatile Design: Suitable for both simple and complex structures.

- Quick Installation: Designed for rapid assembly and disassembly, reducing setup time.

Cuplock Scaffolding

Cuplock scaffolding is another modular system that is highly efficient and widely used in construction projects, including masonry work. Its simplicity and robust structure make it a favored choice.

- Minimal Components: Uses fewer components than traditional scaffolding types, simplifying the assembly process.

- High Load Capacity: Can support substantial weights, making it ideal for masonry involving heavy bricks and materials.

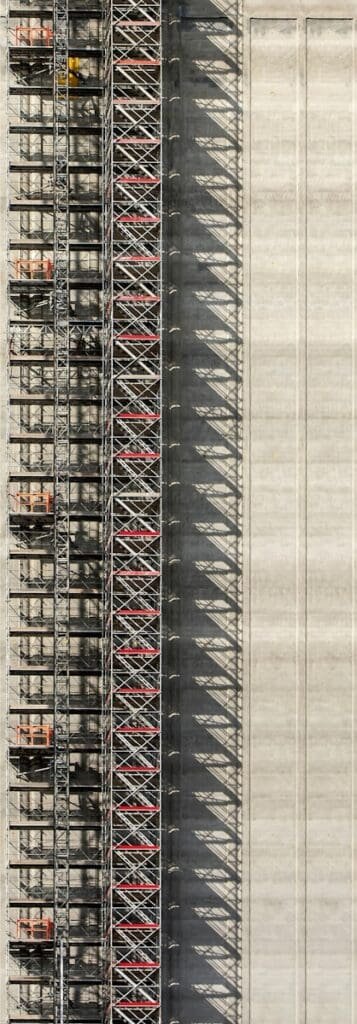

Mast Climbing Scaffolding

Mast climbing scaffolding is a relatively advanced system, offering motorized elevation and adjustable platforms. It’s particularly useful in high-rise brick masonry projects.

- Motorized Lifts: Platforms can be raised and lowered easily using motorized systems.

- Enhanced Safety: Provides a secure platform for workers, reducing accidents and increasing safety.

- Efficiency: Increases productivity by allowing workers to reach different levels quickly without needing to disassemble and rebuild the scaffold.

For more detailed examples and advice on selecting the right masonry scaffolding, you can refer to resources like Safety Management Group’s Masonry Guide.

How Wide is Masonry Scaffolding?

Standard Widths of Masonry Scaffolding

The width of masonry scaffolding can vary based on the type of construction and the specific needs of the project. Here are some common standards:

- Basic Width: The most common width for scaffolding platforms is typically between 29 and 36 inches. This range offers a balance between accessibility and stability.

- Double Width: For projects requiring more space, such as when handling bulky materials, double-width scaffolding platforms can be used which generally measure around 60 to 72 inches wide.

Modular Scaffolding Width Adjustments

Modular scaffolding systems provide the advantage of customizable widths:

- Adjustable Options: Modular scaffolds can be adjusted to a variety of widths by adding or removing components. This allows for flexibility in fitting the scaffold to specific project requirements.

- Configuration: Depending on the project needs, different modules can be combined to create custom widths. For example, wider platforms might be created for larger facade work.

Regulations and Safety Considerations

Adhering to safety regulations is paramount when setting up masonry scaffolding. Here are key considerations regarding scaffold widths:

- OSHA Standards: The Occupational Safety and Health Administration (OSHA) has strict guidelines on scaffolding dimensions to ensure worker safety. According to OSHA, the platform width should be sufficient to prevent falls, typically at least 18 inches wide if used as a working platform, though 24 inches is preferred for added safety.

- Barrier Requirements: For wider scaffolds, additional guardrails and toe boards may be required to provide further protection against falls and material spillage.

Practical Examples

Understanding how width plays a role in various real-world applications of masonry scaffolding:

| Width | Application |

|---|---|

| 24 inches | Standard residential construction |

| 36 inches | Commercial buildings with heavy material handling |

| 48 inches | Large-scale industrial projects |

For additional technical guidelines and safety protocols, visit sources like OSHA’s Scaffolding Standards.

Wrapping Up the Essentials of Masonry Scaffolding

Masonry scaffolding indeed plays an instrumental role in various construction projects.

It not only offers a safe and stable platform for workers and their materials but also enhances efficiency and adaptability across different job types. By understanding the core components, the types such as single, double, and needle scaffolding, along with the adequate safety measures, one can effectively handle the complexities of building or repairing masonry structures safely.

Remember, each scaffolding type offers unique advantages and is suitable for distinct applications. Hence, choosing the right kind for your project is key. Also, engaging with standards from regulatory bodies, like OSHA, can ensure compliance with necessary safety norms.

Frequently Asked Questions – FAQs

What exactly is Masonry Scaffolding?

Masonry scaffolding is a temporary structure used in construction. It offers support to workers and materials while building or repairing masonry structures like buildings, walls, or other large constructions.

What are the main parts of Masonry Scaffolding?

The primary elements of masonry scaffolding include steel or aluminum tubes, planks or platforms, base plates, and braces for support.

What types of Masonry Scaffolding exist?

Single scaffolding, double scaffolding, and needle scaffolding are the primary types of masonry scaffolding, each with their unique features and uses.

Why is safety important in Masonry Scaffolding?

Safety measures like setting up on a stable ground, regular inspections, maintaining recommended weight limits, and wearing personal protective equipment are vital to avoid accidents and injuries while working on scaffolds.

What are the benefits of Masonry Scaffolding?

Masonry scaffolding offers stability, adaptability, and enhances efficiency in construction projects. It allows easier access to high and hard-to-reach places while maintaining safety.