Unravelling the Dielectric Withstand Voltage Test

The Dielectric Withstand Voltage Test, also known as the Hipot test, is a crucial term in the construction world. It’s the process of applying a high voltage to insulate components to verify insulations’ effectiveness.

This test plays a pivotal role in determining the quality and safety of electric devices on construction sites. Its importance cannot be overstated, ensuring that all equipment used is reliable and helps prevent accidents before they happen.

Knowing its ability to detect any electrical issues early makes the Hipot test an invaluable tool for any construction project. To put it simply, it’s all about safety and efficiency in operations.

Table of Contents

What is the Dielectric Voltage Withstand Test?

The dielectric withstand test, also known as a high potential or ‘hi-pot’ test, is a technique to evaluate the insulation properties of an electric device.

This non-destructive test method is designed to check for any excessive leakage current flow caused by faulty workmanship, strains or degradation of an insulation system.

It measures an electrical device’s ability to operate under normal and abnormal conditions without becoming hazardous due to insulation breakdown.

How the Dielectric Voltage Withstand Test Works

The test involves subjecting the device under test (DUT) to a higher voltage than that encountered under normal operating conditions, hence the term ‘high potential’. The objective is not to measure its operational performance, but to ensure that its insulation can withstand higher stress without leading to its breakdown.

Key Components Of The Dielectric Voltage Withstand Test

There are three critical components to this test:

- Dielectric: The insulating material separating electrical components.

- Voltage: An electrical force that potentializes the current’s movement. In our context, this force is increased beyond normal functioning levels to test the limits of dielectrics.

- Withstand: The capacity of the insulating component to resist breaking down under increased voltage levels.

Applications of the Dielectric Voltage Withstand Test

The dielectric voltage withstand test applies at various stages within the electrical field:

- Part of production line testing for consumer products and commercial electrical equipment

- Routine testing during maintenance of electrical installation

- Incoming inspection testing of component parts or devices

In the field of construction and manufacturing, the Dielectric Voltage Withstand Test plays an essential role in assuring the safety and efficiency of various electrical devices and components. With its apt analysis of an electrical system’s insulation properties, it paves the way for high-performing and reliable electrical installations.

To find out more about how these work, check here.

Unpacking Dielectric Strength and Withstand Voltage

In order to go deeper into the concept of Dielectric Voltage Withstand Tests, we must first understand the fundamental terminology associated with these procedures – particularly ‘dielectric strength’ and ‘withstand voltage’.

These two terms are similar in scope but there are key distinctions between them that are crucial for fully comprehending why and how we perform these tests.

What is Dielectric Strength?

Dielectric strength, defined in terms of electric field strength, is the maximum electric field that a pure, non-conductive, inert material can withstand under ideal conditions without undergoing electrical breakdown or failure (Electronics Tutorials).

This value represents the limit beyond which, if subjected to increased voltage, the material might experience an abrupt decrease in insulating properties, leading to a ‘breakdown’ that could result in total insulation failure.

Measuring Dielectric Strength

The units used to measure dielectric strength are volts per meter (V/m).

Different materials have different dielectric strengths. For example, dry air has a dielectric strength of about 3 million V/m, while a perfect vacuum has almost infinite dielectric strength. In lab conditions, dielectric strength assessments typically involve gradually raising the applied voltage at a constant rate until breakdown is observed.

The resulting breakdown voltage is then divided by the sample thickness to obtain the dielectric strength.

What is Withstand Voltage?

Withstand voltage, also known as breakdown voltage, is the maximum voltage that a material or electrical device can tolerate before undergoing considerable and irreversible damage or breakdown. It is a critical value in testing as well as in designing electrical devices because it determines the maximum voltage that can be applied to a device without the risk of failure.

How Withstand Voltage Relates to Dielectric Strength

While dielectric strength is an intrinsic property of a material, withstand voltage pertains more specifically to an actual device or component, considering its realistic conditions, construction, and materials (Hipot). In this context, the dielectric withstand test helps confirm that the insulation’s actual withstand voltage (in the finished product) aligns with the theoretically calculated value based on dielectric strength.

Why the Difference Matters

Understanding the difference between dielectric strength and withstand voltage is important because it informs how tests should be conducted and interpreted. Consideration of both parameters enables better selection of materials in the design phase and ensures safer and more reliable electrical devices and installations.

So, while dielectric strength and withstand voltage are closely linked concepts, they serve individual purposes in the sphere of electrical testing. By distinguishing between the two, we can make more informed production decisions, improve safety guidelines, and enhance the overall quality of electrical products and installations.

For more in-depth explanations and examples regarding these key concepts, visit Impedans.

Deciding the Voltage for Dielectric Strength Test

In the world of electrical testing, deciding the suitable voltage for dielectric strength or withstand tests often entails balancing safety assurance and potential damages to the device under test (DUT). It’s a delicate art based on several factors.

Basics of Determining Testing Voltage

Testing voltage must exceed the operating or peak voltage of the component or system as the goal is to identify the device’s capacity to resist insulation failure under stress conditions. However, testing voltage shouldn’t be unreasonably high as it may damage the DUT or give inaccurate test results.

Methods to Define the Right Voltage

There are general rules established in international standards boards like IEEE, IEC, and UL to guide the selection of an appropriate voltage level for dielectric strength tests.

- Standard Guidelines: Often the testing voltage is predefined by industry standards relevant to the device. These standards consider factors like the component’s insulation type, its intended usage, and the environment in which it operates.

- 1.5 Rule: If not specified by the standards, a commonly used guideline is the “1.5 Rule”, which states that the test voltage should be 1.5 times the device’s nominal rating plus 1000 volts (Protec).

- Manufacturer’s Instructions: Manufacturer recommendations can also be taken into consideration while deciding the test voltage.

Importance of Accurate Voltage Application

Applying the right voltage value in dielectric strength tests is crucial to guarantee both safety and device efficiency. While an insufficient voltage might create a false sense of security, an overly high voltage can harm the device and misrepresent its performance characteristics.

Outcome of Incorrect Voltage Values

Choosing a voltage level lower than required might overlook potential weaknesses in insulation, thereby allowing faulty devices to pass the test. Conversely, applying too high a voltage could cause an unnecessary failure, leading to rejection of components that would have been otherwise safe for normal operation.

Establishing the correct voltage level for a dielectric strength test entails knowledge and proper judgement. Complying with established norms and understanding the DUT’s specific requirements are crucial to ensure the continued safety and efficiency of electrical devices. Thus, while the process may seem complicated, it is a necessary component for reliable electrical testing.

Explore more on voltage determination for dielectric testing here.

Detailed Process of the Dielectric Voltage Withstand Test

Now that we’ve established the importance and basic components of a Dielectric Voltage Withstand Test, let’s delve into the meticulous process of this essential safety test.

Preparation for the Test

Proper preparation is crucial for reliable testing results and safety of both the operator and the device. The testing environment must be free of dust, extreme temperatures or humidity as these can affect the insulation’s properties. Additionally, ensure that the testing equipment is in excellent condition and well calibrated.

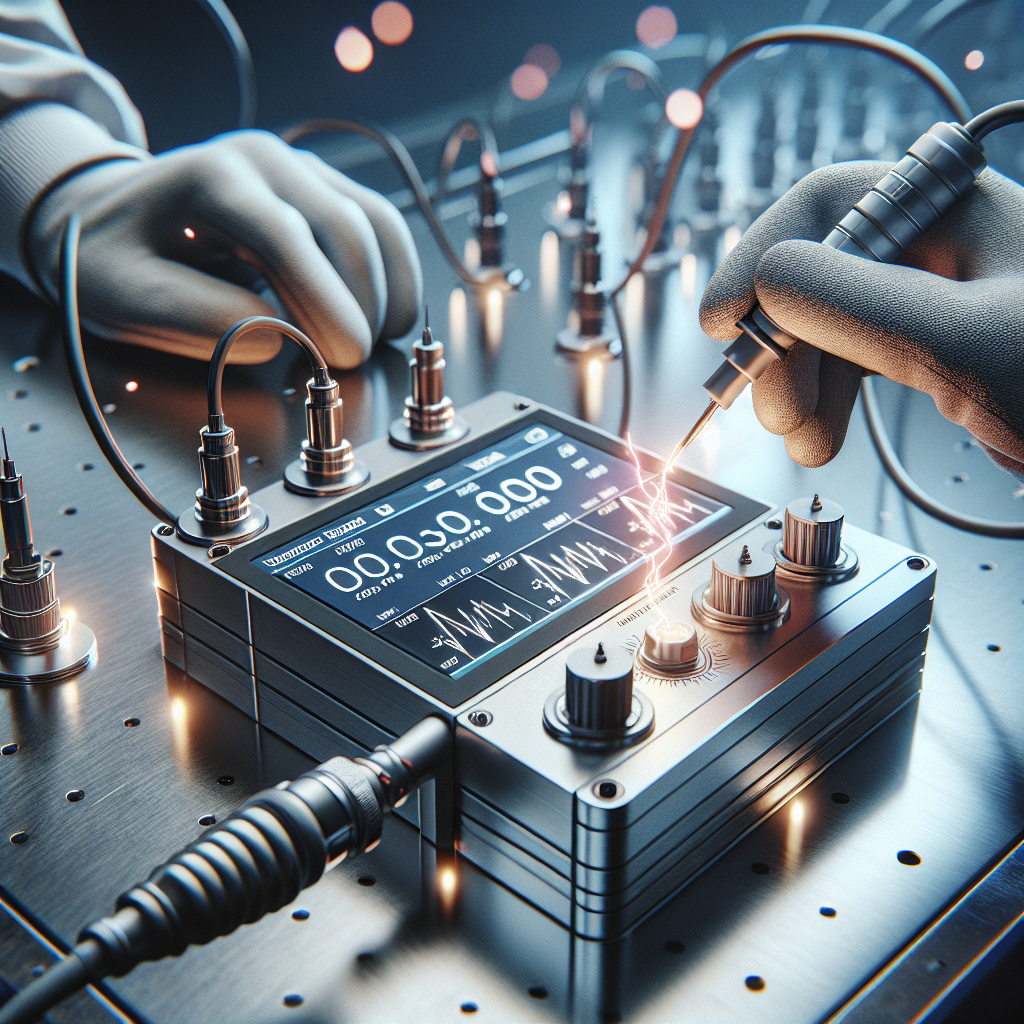

Testing Equipment

A common instrument used for dielectric voltage withstand test is the Hipot tester. This device can generate high voltages, measure leakage current and can automatically shut off if the device under test (DUT) fails.

Performing the Test

Once adequate preparation is complete, the test can be executed. However, always make sure to follow safety precautions to avoid electrical hazards.

Test Steps

- Connect the Hipot tester to the DUT following the instructions from the tester’s manufacturer.

- Set the desired testing voltage level with regard to the nature of DUT and the predetermined guidelines.

- Turn on the Hipot tester and gradually elevate the voltage to the pre-set level.

- Maintain this voltage for a specific period, often for about one minute.

- Evaluate the leakage current. If it’s above the threshold level, the DUT fails the test.

Understanding the Test Results

Interpreting test results accurately is pivotal for safety assessments and making informed manufacturing decisions.

Pass or Fail Criteria

A device passes the dielectric voltage withstand test if it withstands the high voltage without exceeding the permissible leakage current. If the device fails, it indicates significant faults in the insulation that may pose safety risks.

Post-test

After the test, it’s important to handle the DUT with extreme care as it may retain some residual charge. Using the discharge feature on the Hipot tester helps avoid potential electric shocks.

Conducting the Dielectric Voltage Withstand Test is a meticulous process demanding a stringent adherence to safety norms and careful interpretation of results. By following the steps meticulously, companies can ensure they manufacture safe and reliable electrical devices.

For more information on conducting the Dielectric Voltage Withstand Test, you can refer here.

Conclusion on Dielectric Voltage Withstand Test

In our article understanding the Dielectric Voltage Withstand Test, we’ve found that it holds a significant place in electrical installation and appliance manufacturing, safeguarding against potential safety hazards.

This test methodically evaluates insulation effectiveness and electrical durability, bringing a new dimension of reliability in the world of electrical devices.

From our perspective, the three cardinal elements of this test – Dielectric, Voltage, and Withstand – work in harmony to validate an electrical system’s fortitude against abnormal conditions. Its practical applications span various stages within the electrical field, emphatically attesting to its relevance and necessity.

As we see it, the Dielectric Voltage Withstand Test underpins the integrity of an electrical system, making it an essential part of the safety assurance procedures. Its critical role in assuring the reliability of our everyday electrical devices cannot be understated.