the Heat Run Test in Construction

The Heat Run Test is a vital process in construction. Essentially, it’s a specialized form of testing which evaluates the thermal characteristics of various construction materials.

In practical application, it serves to establish a material’s capability to withstand elevated temperatures, ensuring stability and safety in the finished structure.

By applying this test, contractors are able to guarantee quality, thus reducing the risk of collapse or damage caused by heat exposure in the future.

Table of Contents

Understanding Construction Terms: Generator Heat Run Test

What is a Generator Heat Run Test?

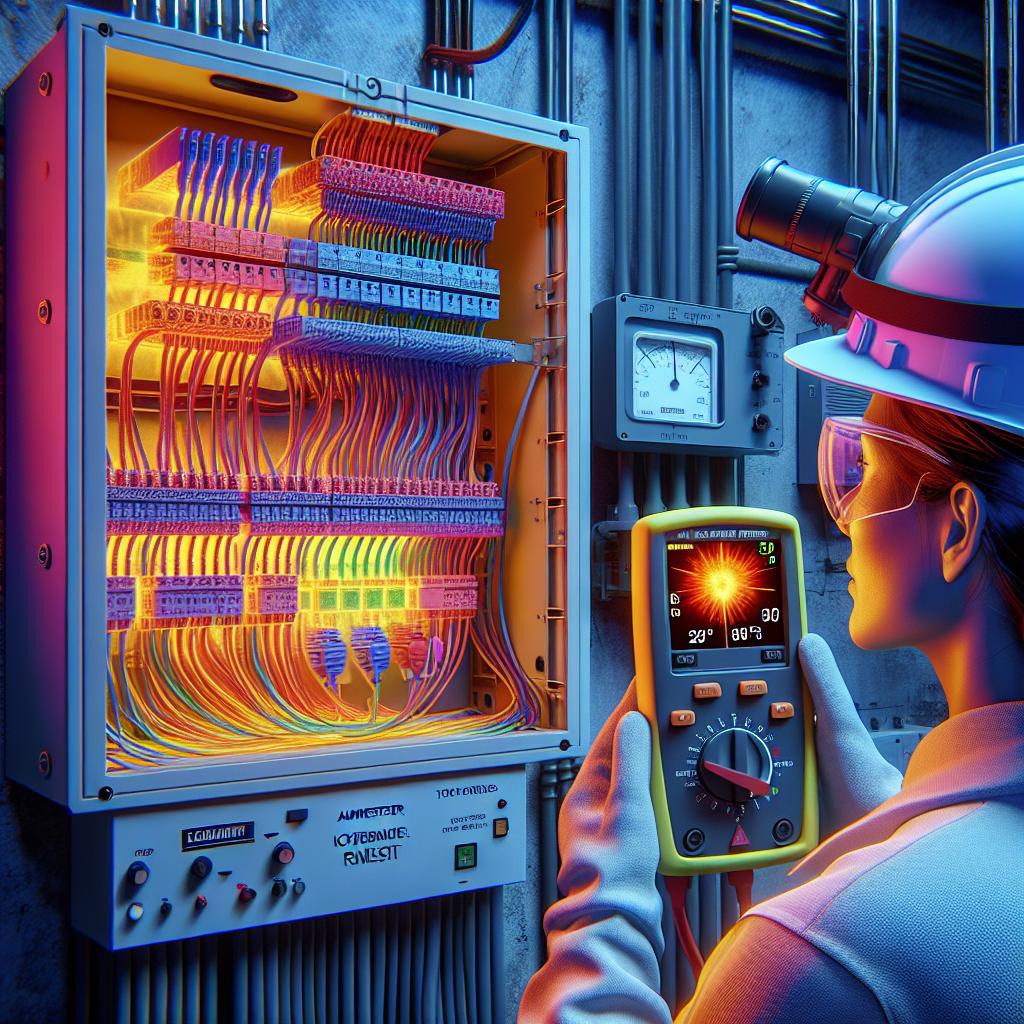

A generator heat run test is a crucial procedure conducted on a generator set to ensure its proper functioning before it is put into service. This test mimics operating conditions to validate the generator’s performance under load and assess its thermal characteristics.

Importance of Generator Heat Run Test

- Verifies the generator’s ability to sustain prolonged operation

- Detects potential issues like overheating or mechanical failures

- Assures reliability and compliance with safety standards

How is a Generator Heat Run Test Conducted?

Here is a general overview of the steps involved in performing a generator heat run test:

| Steps | Details |

|---|---|

| 1 | Preparation: Ensure the generator is correctly connected to the load bank. |

| 2 | Initial Checks: Verify all settings and safety measures are in place. |

| 3 | Load Application: Gradually apply loads to the generator in stages. |

| 4 | Data Collection: Monitor and record parameters like temperature, voltage, and current. |

| 5 | Endurance Test: Run the generator for an extended period to evaluate its performance. |

| 6 | Analysis: Assess the data collected to identify any anomalies or deviations. |

| 7 | Documentation: Compile a report detailing the test results and findings. |

Key Takeaways

- A generator heat run test is vital for ensuring the reliability and performance of a generator before deployment.

- Proper preparation, monitoring, and analysis are essential for conducting a successful test.

- Regular maintenance and testing help prevent unexpected failures and downtime.

Going Deeper into the Generator Heat Run Test

The Significance of the Temperature Rise Test

The temperature rise test is an integral aspect of the generator heat run test, and its primary objective is to validate the generator’s thermal capabilities. Essentially, the test measures and validates the generator’s ability to effectively dissipate generated heat under load conditions.

Why the Temperature Rise Test Matters

- It establishes the thermal operating limits of the generator thereby preventing any potential heat damage or thermal-related breakdowns.

- It determines the generator’s thermal efficiency, shedding light on the proportion of the operating power effectively converted into mechanical or electrical energy, with the remnant being dissipated as heat.

- It contributes to the formulation of efficient cooling strategies, ensuring that excessive heat is expelled and that the generator operates within safe parameters.

The Proper Execution of the Temperature Rise Test

Properly executing the temperature rise test is essential for obtaining accurate results. It involves several essential steps:

| Steps | Details |

|---|---|

| 1 | Monitor Generator: Keep track of key generator parameters, including operating temperature, frequency, and power output prior to the test. |

| 2 | Apply Load: Gradually increase the load to the generator, ensuring it is working within its risk-free operating limits. |

| 3 | Record Data: Constantly log the rise in the operational temperature as the load levels fluctuate. |

| 4 | Remove Load: Gradually remove the load from the generator while measuring how the temperature drops. |

| 5 | Analyse Data: Compare the temperature rise under load conditions to the temperature fall when the load is removed. Identify any anomalies or significant deviations from the expected limits. |

Insights Drawn from the Temperature Rise Test

The results of the temperature rise test can offer several invaluable insights:

- Establishing the thermal management capabilities of the generator.

- Determining the generator’s thermal efficiency ratio.

- Identifying potential weaknesses before field deployment, allowing for preventative measures to be put in place.

Final Thoughts

While the generator heat run test ensures the reliability of the generator, regular temperature rise tests serve to confirm the thermal efficiency of the generator and its ability to manage heat dissipation. These tests offer an effective approach to preemptively mitigate potential failures, thus reinforcing the generator’s reliability and enhancing the generator’s operational performance in the field.

Decoding Transformer Temperature Tests

Understanding Transformer Temperature Tests

In parallel to generator heat run tests, transformer temperature tests, also known as ‘heat run tests’ or ‘temperature rise test’ on transformers, are an essential aspect of transformer testing. Like generator heat run tests, transformer temperature tests verify operational safety, stability, and efficiency under specific load conditions.

The Purpose of Transformer Temperature Tests

- They evaluate the transformer’s thermal behavior under normal and overload conditions.

- They verify correct thermal design and the transformer’s ability to withstand temperature rise without detrimental effects on the insulation or other components.

- They enable the user to establish cooling strategies to prevent overheating and extend the transformer’s lifespan.

How are Transformer Temperature Tests Conducted?

The process for conducting a transformer temperature test is strategic and systematic:

| Steps | Details |

|---|---|

| 1 | Start-up: Connect the transformer under testing conditions, and ensure all safety measures are in place. |

| 2 | Load: Apply the calculated load to the transformer following the test plan. |

| 3 | Monitoring: Gradually increase the load while monitoring key transformer parameters like oil and winding temperatures. |

| 4 | Data Recording: Document data like oil temperature rise, winding temperature rise, and overall temperature at regular intervals. |

| 5 | Review: Analyze the collected data to evaluate the transformer’s thermal performance. |

| 6 | Report: Compile and submit a detailed report of the findings. |

Insights from Transformer Temperature Tests

The outcomes of the transformer temperature tests offer multiple vital insights:

- Reveal the transformer’s thermal capacity and its ability to handle both standard and overload conditions.

- Uncover potential issues that could result in a failure under high temperature or overload conditions, including internal faults, insufficient cooling, or insulation breakdown.

- Provide real-world thermodynamic data that can help improve transformer design and operation.

Conclusion

Such as generator heat run tests, transformer temperature tests are also essential to ensure operational efficiency, safety, and longevity. These tests provide the means to predict and control the transformer’s thermal behavior, thereby reducing risk, adding a layer of safety, and improving performance under real-world operating conditions.

Exploring Similar Tests: The Temperature Rise Test on a Circuit Breaker

What is a Temperature Rise Test on a Circuit Breaker?

A temperature rise test on a circuit breaker is a vital process in assessing and bolstering the safety and performance of the breaker. This procedure involves inducing a current flow at rated capacity through the breaker and monitoring the subsequent temperature increase — the ‘temperature rise’ — within the device. This test attempts to replicate the breaker’s operational temperatures within a controlled environment.

Main Purpose of The Temperature Rise Test

- The test is designed to determine the maximum temperature that the circuit breaker can withstand under full-load conditions without sustaining damage or compromising its safe operational parameters.

- This procedure checks the efficiency of the circuit breaker’s internal heat dissipation mechanisms.

- It ensures that the heat generated by the flow of electricity does not compromise the integrity of the components, thereby maintaining safety and operational stability.

Conducting a Circuit Breaker Temperature Rise Test

The following steps provide an overview of how a temperature rise test is performed on a circuit breaker:

| Steps | Details |

|---|---|

| 1 | Preparation: Connect the circuit breaker in line with the rated load and verify that safety measures are in place. |

| 2 | Initiation: Apply the rated load current to the breaker. |

| 3 | Monitoring: Measure the temperature rise across key components of the breaker at regular intervals. |

| 4 | Data Collection: Record the temperature readings at different time intervals. |

| 5 | Analysis: Assess the recorded temperature data for any excessive temperature rise that may hint at potential performance issues. |

Expected Outcomes and Insights

Conclusions and insights drawn from the temperature rise test on a circuit breaker usually revolve around these principles:

- The temperature rise must be within the designated limits described by the manufacturer or the relevant standards. This assures the breaker’s thermal stability and reliable performance under full load conditions.

- Any abnormal rise in temperature should trigger a thorough investigation as it signals potential issues, such as poor contact integrity, ventilation inefficiency, insulation degradation, or undervalued load rating.

- Regular temperature rise tests help identify and fix problems early, thus ensuring the durable and safe function of the circuit breaker. This mitigates the risk of unexpected failures and extends the lifespan of the device.

Wrap Up

The temperature rise test on a circuit breaker resonates with the same goals as in a generator heat run test, transformer temperature test, and more. It’s a crucial practice to ratify that the equipment can handle its operating temperature range.

Rigorous and regular testing, including temperature rise tests, promotes safety, reliability, and efficiency in electrical systems.

A Conclusion On Heat Run Tests

In conclusion, the generator heat run test serves as a critical validation process for generator sets before they are put into service.

This testing procedure is essential for assessing the generator’s ability to sustain prolonged operation, detecting potential issues such as overheating or mechanical failures, and ensuring compliance with safety standards. By following a structured approach that includes preparation, thorough monitoring, and diligent analysis of the data collected during the test, professionals can effectively evaluate the generator’s performance and reliability.

Regular maintenance and testing, including the generator heat run test, play a key role in preventing unexpected failures and minimizing downtime, thereby enhancing overall operational efficiency and resilience in power generation systems.

It is evident that the meticulous execution of the generator heat run test is crucial for verifying the readiness and robustness of generators in various applications, emphasizing the significant impact of this testing procedure on ensuring uninterrupted power supply and equipment longevity.