An Overview of the Guy Strain Insulator in Construction

The term ‘Guy Strain Insulator’ might seem jargon-heavy. Don’t fret. It’s rather simple, really.

In construction realms, a ‘Guy Strain Insulator’ is a pivotal component. It primarily functions to prevent electric wires from grounding or short circuiting.

This practical functionality is achieved by insulating the guy wires. These wires provide stability to the structures they are attached to.

Let’s jump in.

Table of Contents

What’s the Role of a Guy Insulator?

Key Responsibilities of a Guy Insulator:

- Installing guy wires: Guy insulators are tasked with properly positioning and securing guy wires to ensure the stability of poles or towers.

- Insulating guy wires: They are responsible for applying insulating materials to guy wires to protect them from environmental factors and prevent electrical conduction.

- Ensuring safety compliance: Guy insulators must adhere to safety regulations and protocols to safeguard themselves and others during installations.

- Inspecting and maintaining installations: Regular inspections and maintenance of guy wires are crucial to assess their condition and address any wear or damage promptly.

Why Guy Insulators are Essential in Construction

Guy insulators play a vital role in the overall safety and functionality of construction projects. By diligently carrying out their duties, they contribute to the longevity and reliability of infrastructure installations.

Conclusion

Now that you understand the role of a guy insulator in construction, you can appreciate the importance of their tasks in ensuring structural stability and safety within the industry. Stay tuned for more insights on construction terms and practices!

Diving into Details: Understanding the Strain Insulator

Introduction to Strain Insulators

While we’ve discussed the importance of guy insulators in construction, a closely related component that’s equally critical is the strain insulator. Various industries, not just construction, use this key element. Let’s explore what strain insulators are and their significance.

Strain Insulator: What is it?

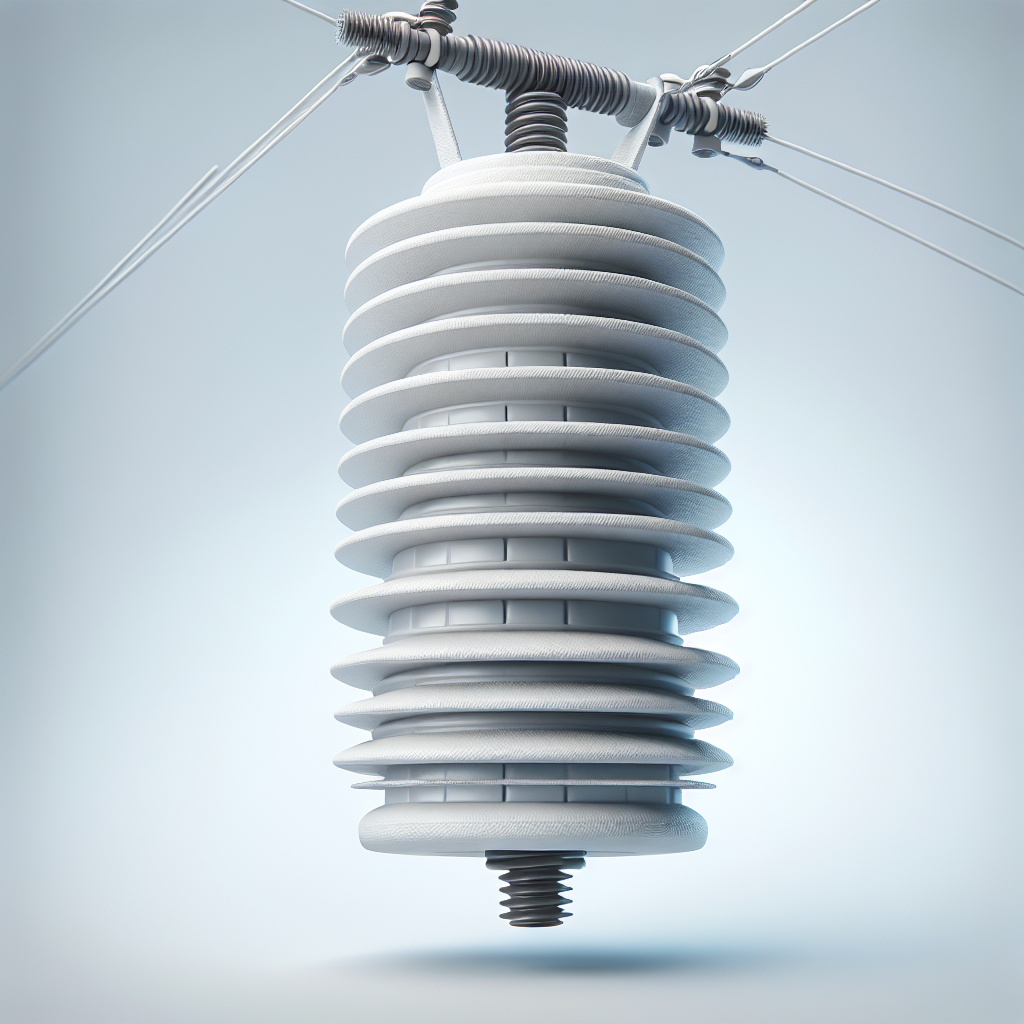

Strain insulators are utilized extensively for overhead power distribution systems, telecommunications, railway electrifications, and similar areas where tension needs to be managed. They’re frequently employed in conjunction with guy insulators within a construction setup. They deliver exceptional performance in spreading tension over several wires or cables to prevent their breakage.

Roles and Tasks of a Strain Insulator

- Distributing Tension: Strain insulators effectively redistribute tension over multiple wires, which helps prevent breakage and increase the lifespan of the installation.

- Insulation: They also provide insulation between the tensioned cables and the pole or tower, preventing electrical flow from the cable to the structure.

- Safety: Just like guy insulators, strain insulators play an integral part in maintaining safety standards during installation and operation.

- Evaluating and Maintaining Installations: Regular inspection and maintenance are essential to ensure optimal functioning over time.

The Significance of Strain Insulators in Various Industries

Strain insulators render critical support in power transmission, telecommunication systems, and other sectors wherein tension, electricity, and safety are crucial factors. Their ability to insulate and perform effectively under high-tension situations allows for the safe and efficient operation of these industries.

Conclusion

Understanding the role of strain insulators in the broader context helps to appreciate their contribution to safety and functionality in various sectors, including construction. Keep following to gain more insights into other fascinating technical terms.

Painting a Clearer Picture: Insulation Materials Used in Guy Cables

Introduction to Insulation Materials

Now that we have established the role and importance of guy insulators and strain insulators, let’s delve deeper into the materials used for insulating guy cables. It’s essential to understand why certain materials are chosen over others and their effect on the guy cable’s overall function and performance.

Materials used for Insulation

The key to a good insulator is its ability to resist electrical conduction. Different materials possess varying levels of this characteristic, leading to widespread use in various settings such as construction sites. The most common materials used for insulating guy cables are porcelain, glass, and composite polymers.

Porcelain Insulators

Porcelain is a very common insulator used in guy cables. Its popularity is driven by its high dielectric strength, thermal stability, and resistance to environmental factors.

Glass Insulators

Glass, like porcelain, possesses high dielectric strength and offers excellent moisture resistance. They are easy to inspect for defects due to their transparent nature, an advantage over other insulating materials.

Composite Polymer Insulators

Composite polymer insulators, made from a combination of synthetic hydrocarbons, have become increasingly common in recent years. They offer lower weight, corrosion resistance, and superior performance in severe environmental conditions. Their flexibility also makes them less prone to breakage.

How Insulator Material Choice Affects Performance

The material chosen to insulate guy cables can significantly affect the performance of the entire system. For instance, the amount of electrical resistance, physical durability, and resistance to environmental conditions can directly impact the longevity and reliability of the construction. Therefore, the selection of the insulator material is a crucial decision.

- Electric Resistance: The insulator’s ability to resist the flow of electricity, known as electric resistance, can vary widely based on the material, affecting the insulator’s effectiveness.

- Durability: The material’s durability can dictate how long an insulator will last. For example, while glass insulators offer strong electric resistance, they can be susceptible to damage from physical impact.

- Environmental Resistance: Different materials can respond differently to various environmental conditions such as heat, cold, moisture, and corrosive elements. A good insulator will resist these elements to maintain performance.

Peering Deeper: Examining Suspension & Strain Insulators

Introduction to Suspension and Strain Insulators

With the essential roles of guy and strain insulators established, a further element to unravel is the distinction between suspension and strain insulators. Though they may appear similar, they perform different roles within infrastructure setups. To get a real sense of their unique impacts, it’s important to explore both in more depth.

Suspension Insulator: Definition and Duties

Suspension insulators are primarily used in transmission lines and distribution systems. Their construction incorporates several insulating materials connected in a series or chain, suspended from a tower, and carrying the conductor at the bottom end. Their main purpose is to absorb mechanical stress induced by the weight of the transmission line and any environmental factors, such as wind.

Key Functions of a Suspension Insulator

- Handling Mechanical Stress: Suspension insulators are designed to bear the load and stress of the conductor while also protecting the pole or tower from the mechanical strain.

- Electrical Insulation: They also serve as an effective electrical insulator, preventing the electrical current from flowing into the tower or pole.

- Flexibility: Due to their chain-like design, suspension insulators can swing or move in different directions, absorbing shocks and dynamic loads effectively.

Strain Insulators vs. Suspension Insulators

While both strain and suspension insulators offer essential support in power transmission and distribution systems, the pivotal difference lies in their application and design.

| Characteristic | Strain Insulators | Suspension Insulators |

|---|---|---|

| Primary Purpose | Managing high tension situations by redistributing tension over multiple wires to avoid their failure. | Absorbing mechanical stress induced by weight of the line and environmental factors such as wind. |

| Design | Single or multi-part design depending on the tension requirement. Generally mounted in a horizontal position. | Chain-like design mounted vertically to absorb load and swing in various directions. |

| Usage | Used in locations with high-tension load, such as corner and end posts in power lines. | Common in high voltage overhead transmission and distribution lines. |

Summing It All Up

In conclusion, the role of a guy insulator in construction is crucial for maintaining the structural integrity, safety, and functionality of infrastructure installations.

Their responsibilities of installing and insulating guy wires, ensuring safety compliance, and conducting regular inspections are essential for the longevity and reliability of construction projects.

By understanding and appreciating the importance of guy insulators, we recognize their significant contributions to ensuring structural stability and safety within the construction industry. Keep an eye out for more insights on construction terms and practices to deepen your knowledge of the field.