Introduction to the Frequency Transducer in Construction

A frequency transducer is a device that converts a signal from one form to another. In construction, they play an integral role.

These devices mainly handle measurement-related tasks, thus aiding the precision and quality of the projects. Frequency transducers help ensure that machinery and tools operate at the correct speed and intensity.

Essentially, they help to simplify complex processes and maintain the high standard in the construction projects. Stay tuned for deeper insight into how this technological gem is transforming the construction industry.

Understanding Construction Terms: High Frequency Ultrasound Transducer

Introduction

In the realm of construction, various tools and equipment are utilized to ensure precision and efficiency during different phases of a project. One such essential device is the high frequency ultrasound transducer.

What is a High Frequency Ultrasound Transducer?

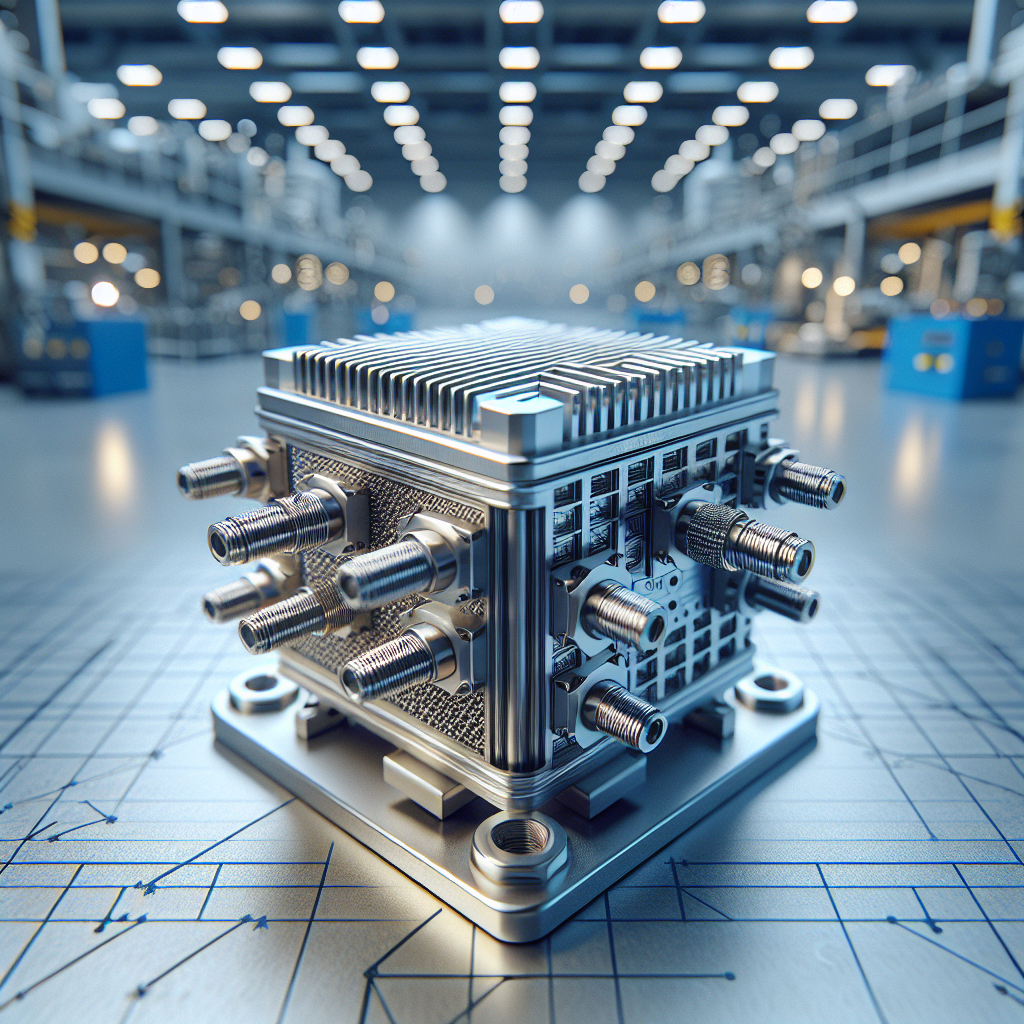

A high frequency ultrasound transducer is a specialized tool that emits ultrasound waves at a frequency higher than the standard ultrasound devices. This technology allows for more detailed and accurate imaging of structures within materials.

Applications in Construction

High frequency ultrasound transducers find extensive applications in the construction industry due to their ability to provide non-destructive testing of materials. They are commonly used for:

- Detecting internal defects in concrete structures

- Evaluating the quality of welds in metal components

- Measuring the thickness of materials like concrete, steel, and composites

Benefits of Using High Frequency Ultrasound Transducer

Utilizing high frequency ultrasound transducers in construction offers several advantages, including:

- Enhanced resolution for accurate inspection

- Non-invasive testing, reducing the need for destructive methods

- Improved safety by detecting potential issues early

Conclusion

In summary, a high frequency ultrasound transducer is a valuable tool in the construction industry for conducting precise and non-destructive testing of materials. Its high-frequency capabilities enable detailed imaging and inspection, contributing to the overall quality and safety of construction projects.

Deciphering the Transducer: Ringing In Ultrasound Functionality

Transducer: The Heart of Ultrasound

At its most rudimentary, a transducer in the context of ultrasound technology is a device that transforms one form of energy into another. In the high frequency ultrasound transducer discussed, the conversion is from electrical energy to sound waves, then back to electrical energies. But how does a transducer perform such a vital function?

The Anatomy of a Transducer

A typical transducer is comprised of an active element often made of special ceramic, crystal or composite materials that have piezoelectric properties. This implies that they can change their shape rapidly when an electric field is applied.

Transducer Functionality: A Play of Energies

Upon receiving an electrical signal from the ultrasound machine, the piezoelectric materials within the active element of the transducer oscillate and produce sound waves. These sound waves are then sent through a medium (like the material under inspection in the construction industry). When these sound waves hit a boundary between substances (like a defect within a concrete structure), some of the wave energy is reflected back to the transducer that converts these sound waves back into electrical energy. The ultrasound machine processes this returned electric energy into an image or data we can interpret.

Classification of Transducers: A Peek into Versatility

Notably, transducers are not one-size-fits-all tools; they come in various shapes and sizes, categorized into different types such as linear, curved, or phased array, each suitable for a wide range of tests and inspections.

The Transducer-Device Synchronization: Backscattering and Attenuation

The frequency of the transducer translates directly to how deep the sound waves can penetrate the material, and the resolution of the resulting image. The intricate balance of penetration depth and resolution is determined by the material’s backscatter and attenuation. Backscatter refers to the scattered sound waves reflected back to the transducer, while attenuation refers to the decrease in intensity of sound waves as they pass through a material.

| Frequency | Penetration Depth | Resolution |

|---|---|---|

| High | Lower | Higher |

| Low | Higher | Lower |

Conclusion

In essence, the transducer in ultrasound technology serves as a critical echo-sounder, transforming electrical energy into sound waves and back again to provide valuable imagery or data. It’s a sophisticated symphony of energies – electrical, sound, elastic – that can make or break inspections in construction and beyond.

Low Frequency Transducers: When Deeper Matters More

The Low Frequency Transducer: A Contrasting Tool

A low frequency transducer works similarly to its high frequency counterpart, but there’s a key distinction: it uses lower frequency ultrasound waves. While high-frequency transducers generate detailed imaging with a shallow penetration depth, low-frequency types prioritize deeper penetration at the expense of image resolution.

Why Use a Low Frequency Transducer?

Low frequency transducers prove beneficial in circumstances where deeper penetration is imperative, and high-resolution imaging is less critical. Certain construction tasks necessitate a thorough assessment of deep-seated, larger structures which could pose significant safety risks if not meticulously examined. Here, higher penetration depth of low frequency transducers becomes crucial.

Potential Scenarios for Low Frequency Transducer Use

Some examples where low frequency transducers outrank their high-frequency counterparts in usefulness include:

- Evaluating the overall structural integrity of large concrete buildings

- Detecting and locating larger subsurface defects in extensive bridges

- Assessing the condition of deep foundation piles in significant structures like skyscrapers

The Science Behind Depth vs Resolution Trade-Off

The phenomenon of penetration depth and resolution inversely related is attributed to how sound waves travel. Higher frequency sound waves are absorbed more quickly while penetrating a medium, limiting their depth reach. Conversely, lower frequency waves, while having less resolution, are absorbed less and can delve deeper into structures. Therefore, selecting between high or low frequency transducers is determined by the specific requirements of the inspection task at hand.

Conclusion

In conclusion, high frequency ultrasound transducers provide the necessary detailed imaging required for intricate evaluations. However, it’s the low frequency transducers that excel when deeper penetration into large structures is vital for assessment, despite offering less resolution. Each transducer type has its intrinsic strengths, therefore the choice of transducer relies heavily on the type of application, and the kind of balance required between depth and resolution.

Discovering the Highest Frequency Transducer

High Frequencies: Beyond the Typical Range

Although already operating in frequencies above the norm, highest frequency transducers stand out in the ultrasound group as outperformers. These transducers work in frequencies well beyond the standard range, resulting in an even more detailed image at an unsurpassable resolution, albeit with a much lower penetration depth.

Soaring Frequencies, Sharp Details

The highest frequency ultrasound transducers, usually ranging from 20MHz to up to 50MHz, can illuminate even minute discrepancies in a structure. While they yield the highest resolution among transducer types, their penetration depth is rather limited, restricting them to superficial inspections.

Power Player in Niche Use cases

Although their usage may be limited, these high-flyers excel in niche use cases where extreme attention to surface details is required such as:

- Examining thin weld layers or bonds

- Inspecting surface-level cracks and defects on materials

- Microscopically assessing material corrosion

Switching Frequencies

Highest frequency transducers, while providing the highest resolution, are use-case specific and are not viable for deep investigations. Lower frequency transducers, while sacrificing intricate detail, prove more effective when an inspection requires greater penetration. Most modern ultrasound devices are capable of switching frequencies to accommodate diverse inspection requirements, from surface-level detail checking to deep structure examination.

Impact on Construction Industry

The introduction of highest frequency transducers has further expanded the versatility of non-destructive testing in the construction industry. These powerful tools play a pivotal role in maintaining the quality of smaller detailed structures, while lower frequency transducers cover broad and deeper inspections.

Conclusion

With greatly enhanced resolution capabilities, but limited penetration depth, the highest frequency ultrasound transducers have become a significant tool in the construction industry for specific use-cases. Selecting the right frequency–high or low–is crucial to ensuring effective inspections, contributing to the overall safety and quality of construction projects.

Conclusion:

High frequency ultrasound transducers are indispensable assets in the construction realm, offering unparalleled capabilities in non-destructive testing and material evaluation. Their advanced technology empowers construction professionals to detect internal defects, assess weld quality, and measure material thickness with exceptional accuracy and detail.

By leveraging high frequency ultrasound transducers, construction projects benefit from enhanced resolution, non-invasive testing methods, and proactive issue detection. These devices play a pivotal role in ensuring construction quality, safety, and efficiency, ultimately elevating the standards of the industry.