An Introduction to Scaling Resistors

A scaling resistor, in essence, is a device controlling electrical resistance measurements within a circuit.

To put it simply, it modifies signals before they reach the main system.

In the construction world – and everyday life – these are key for managing power distribution efficiently. Ensuring safe, functional environments where electrics are used.

Let’s scale our knowledge and learn a bit more about scaling resistors.

Table of Contents

the Range of Resistance in Construction

What is Resistance in Construction?

Before going into depth on scaling resistors, it’s nice to understand the concept of ‘resistance’ in construction.

But go ahead and skip to the next section if you don’t care for a quick overview on resistance.

Resistance refers to the ability of a construction material to resist or withstand different types of forces or pressures like physical pressures, temperature, weight, etc., without deforming or breaking.

Different Types of Resistance

Resistance can be divided into several types, each reflecting the material’s ability to withstand a specific kind of force or pressure. Some common types include:

- Tensile Resistance: Refers to the material’s ability to withstand tension.

- Compressive Resistance: Represents the material’s ability to resist compression.

- Thermal Resistance: Relates to how well the material can withstand changes in temperature.

What is the Range of Resistance?

The ‘range of resistance’ specifically refers to the minimum and maximum levels of force that a building material can resist without causing any damage or deformation. It represents the strength and durability of a construction material under various stressors.

The Importance of Knowing the Range of Resistance

Knowing the range of resistance of a construction material is crucial for the following reasons:

- Ensures Safety: Materials with the proper range of resistance ensure the safety of the structure.

- Prevents Damage: Using materials within their effective range of resistance prevents deformation and damage.

- Optimizes Performance: It allows for the optimal performance of materials in different environmental conditions.

Measuring the Range of Resistance

The standard measurement of the range of resistance is done through stress tests. These tests measure the amount of pressure a material can withstand until it breaks or deforms. The results of these tests offer a numeric value of the material’s resistance, often known as its ‘strength rating’.

Common Construction Materials and Their Range of Resistance

| Material | Range of Resistance |

|---|---|

| Concrete | 3,000 to 7,000 psi (pounds per square inch) |

| Steel | 40,000 to 60,000 psi |

| Wood (Pine) | 7,400 to 7,600 psi |

Understanding the range of resistance in construction is a crucial aspect of selecting appropriate materials and ensuring the safety and longevity of a structure.

By considering this range, construction professionals can make informed decisions and contribute to the construction of safe and durable buildings.

Now, back to the main focus of scaling resistors.

Translating Resistance into Electrical Component – The Role of Resistors

While resistance is a key concept in construction, it also plays a significant role in the realms of electronics and electrical engineering.

Here, the term “resistance” signifies a particular attribute of an electrical component known as a resistor. The following discussion dives into the world of resistors, explaining the concept of ‘rated value’ as it pertains to these key electronics components.

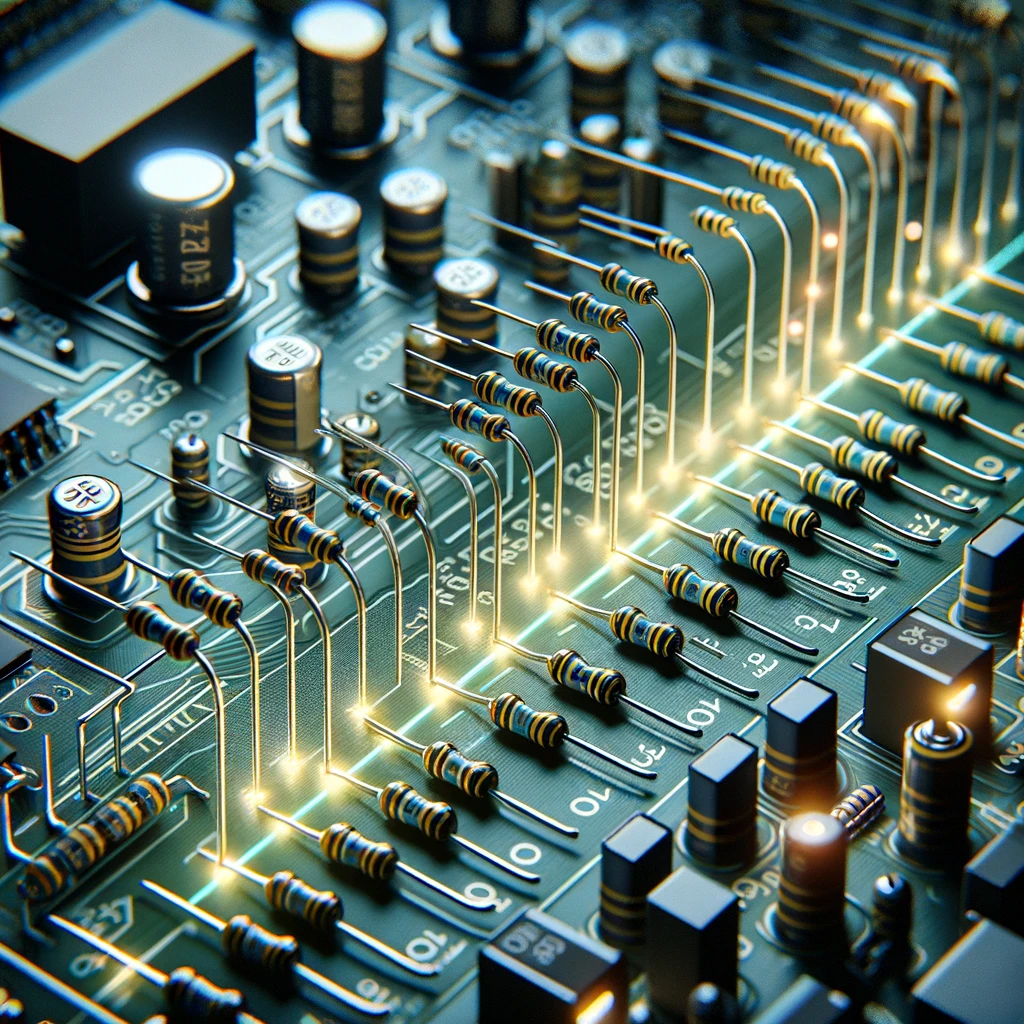

Understanding Resistors in Electronics

In the world of electronics, resistors are integral components. They limit, or “resist,” the flow of electrical current in a circuit.

This ensures that sensitive electrical components aren’t exposed to damaging levels of electric current. Just like construction materials, resistors have a range of resistance characterized by a specific rated value.

What is a Resistor’s Rated Value?

A resistor’s rated value, also known as its nominal value, gives an indication of how much resistance it can offer to electric current.

Usually measured in ohms (Ω), the rated value is set by the manufacturer and noted on the resistor’s body either through color coding or direct numerical marking.

Implications of Rated Value in Circuit Design

The use of resistors with appropriate rated values is essential in the successful design of a circuit. Here’s why:

- Precision: The correct rated value ensures components interact correctly with optimal current flow.

- Safety: Overrated or underrated resistors could lead to potential damage of other delicate components in the circuit or present a fire hazard.

- Functionality: Ensuring the rated value corresponds to circuit requirements supports the overall functionality of the electronic device.

Determining a Resistor’s Rated Value

Typically, a resistor’s rated value is printed directly on the resistor’s body in a standardized color code. Color bands represent different numerical values and multipliers to conclude the resistor’s Rated Value.

Common Resistor Rated Value Examples

| Color Code on Resistor | Rated Value |

|---|---|

| Brown, Black, Red | 1,000 Ω (1kHz) |

| Yellow, Violet, Orange | 47,000 Ω (47kHz) |

| Green, Blue, Yellow | 560,000 Ω (560kHz) |

Whether we are talking about construction materials or electrical components, understanding the concept of resistance and how to quantify it is crucial.

In electrical components, such as resistors, the ‘rated value’ is the key to ensuring safety and optimal operation of electronic circuits. This number, while often overshadowed by the physical microcosm of electronics, is integral in the design of virtually every device that uses electricity.

Why do Resistors Have Different Values?

The intricate realm of electronics presents a vast array of resistors, each differing in its rated or nominal value.

But one might wonder – why is there such a diversity in these values? This section aims to shed light on the reasons behind this variability, deciphering its importance in electronic circuit design.

Adapting to Varied Electronic Needs

Electronic circuits greatly differ in their requirements for current flow, depending upon their functionality and purpose. Devices like smartphones necessitate a different level of current regulation than larger systems like industrial machinery. Hence, resistors are manufactured in a wide range of values to cater to these varying requirements.

Necessities for Specific Components

Specified components within a complex circuit might require distinct current levels to function optimally. Having resistors with different values permits selective current regulation, ensuring the ideal operation of individual components.

Voltage Regulation

Resistor values play a pivotal role in voltage regulation within a circuit. Higher nominal values typically result in a larger voltage drop across the resistor, and conversely, lower values result in a smaller voltage drop. Therefore, resistors of different values enable the design of circuits with precise voltage regulation.

Ensuring Balance in a Circuit

Resistors with varying values are used to balance circuits. For instance, in a voltage divider circuit, different resistor values are used to divide voltage precisely across various components. This mechanism aids in the secure and optimized operation of the overall circuit.

Creating Delayed Timing Circuits

Resistors, in combination with capacitors, are utilized to create delayed timing functions in circuits. The resistor’s value directly influences the delay duration. Higher resistor values result in longer delays, whereas lower values result in shorter delays.

Facilitating Compact Circuit Design

Resistors with diverse values facilitate compact and efficient circuit design. Instead of using a couple of similar resistors in series or parallel to attain a required resistance, a single resistor of the exact value can be used, providing a more space-effective solution.

Resistors showcase a wide array of values to accommodate the multifaceted requirements of electronic circuits.

The distinct values of resistors serve as the backbone of electronic design, contributing to the precision, balance, functionality, and compactness of circuits. Understanding the whys and wherefores of resistor values can enrich one’s comprehension of electronic intricacies, paving the way to better circuit design and troubleshooting.

Factors Influencing Resistance Values in Electronic Components

When studying the concept of resistance, especially in electronic components, it is essential also to discern the factors that determine these resistance values.

These factors dictate the performance and efficiency of components within an electrical circuit. From material composition, temperature, to geometric dimensions, various considerations have a pronounced impact on resistance values.

Material Composition

Not all materials are equal when it comes to resistance. Some materials limit the flow of electric current more than others due to their atomic structure.

Generally, good conductors such as copper and silver offer low resistance, while insulators like rubber provide high resistance. Semi-conductors, like silicon, fall in between and have variable resistance levels.

The Role of Resistivity

Each material has a property known as resistivity, represented by the Greek letter rho (ρ), which quantifies how much that material intrinsically resists the flow of electric current.

Temperature

The resistance of a material tends to increase with temperature. As the temperature rises, the atoms in a material vibrate more intensely, causing more collisions and hindrance to the flow of electrons, resulting in increased resistance. However, the effect of temperature on resistance depends on the type of material. For instance, the resistance of semiconductor materials decreases with an increase in temperature.

Temperature Coefficient of Resistance

The change in resistance with temperature can be quantified using a property known as the temperature coefficient of resistance. This coefficient indicates how much a material’s resistance changes for each degree of temperature change.

Geometric Dimensions

The physical dimensions of an electronic component—its length, cross-sectional area—also play a vital role in determining its resistance. Longer components have higher resistance as electrons have to travel a greater distance. Conversely, components with a larger cross-sectional area offer more pathways for electric current, resulting in lower resistance.

Nature of the Electric Current

The versions of electrical current—direct current (DC) and alternating current (AC)—also influence the resistance. In the case of AC, other factors such as the frequency of the alternating current and the type and state of the material come into play.

Impact of Skin Effect in AC

In AC circuits, the “skin effect” occurs where the current tends to flow near the surface of the conductor, particularly at high frequencies. This results in an effective increase in the resistance of the conductor.

Understanding the factors that influence resistance values in electronic components can be very helpful when designing or troubleshooting circuits. By factoring in aspects such as material composition, temperature, physical dimensions and the nature of an electric current, more effective and efficient circuits can be created.

Signing Off On Scaling Resistors

So here we are, at the end of our article into the concept of range of resistance in construction.

It’s clear that understanding and considering this range is not just a technical requirement but a significant contributor to building safer, more durable, and efficient buildings.

We’ve found that each material has a unique range of resistance, and knowledge of its tensile, compressive, and thermal resistance is vital.

From steel to wood and concrete, the very safety and durability of our structures depend on these measurements.

This brings us to the end of our discussion. From our perspective, it’s apparent that the world of construction is a complex interplay of principles and elements, among which the range of resistance stands as an unwavering pillar.