Introduction To Frogs In Bricks

Welcome to this comprehensive guide about the somewhat mysterious, yet essential component in bricklaying – the ‘frog’.

Ever heard of it?

It may sound strange, but the term ‘frog’ refers to a specific indentation in a brick which serves an essential role in construction.

We’ll explore its function, benefits, manufacturing process, and much more. We’ll also discuss the different types of bricks that use frogs and guide you on how to use them in construction.

By the end of this article, you’ll be well acquainted with the fascinating world of frog bricks!

Table of Contents

Understanding the Role of a Frog in a Brick

Introduction to Brick Frogs

In the context of construction, a “frog” has a specific meaning that is essential for bricklaying. This term may not be familiar to those outside the industry, but it’s important for creating strong and durable brick structures.

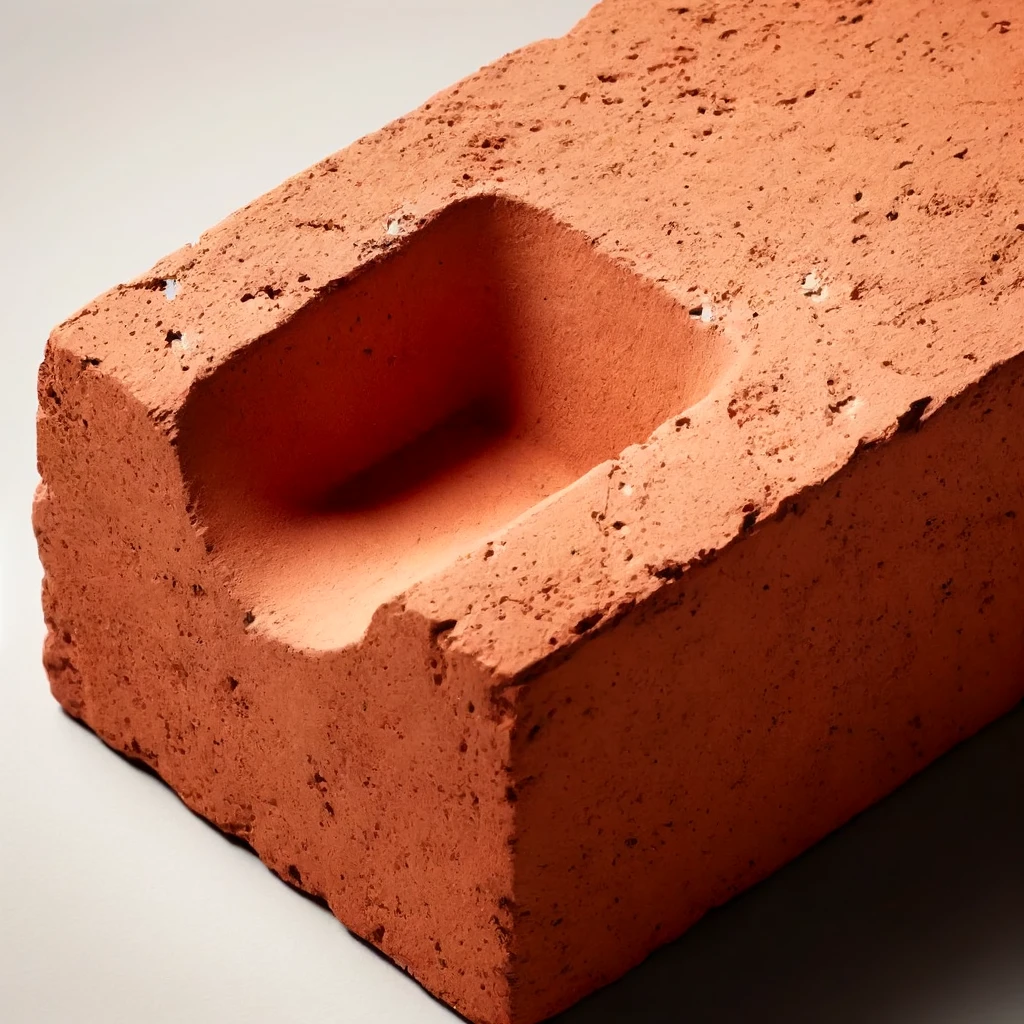

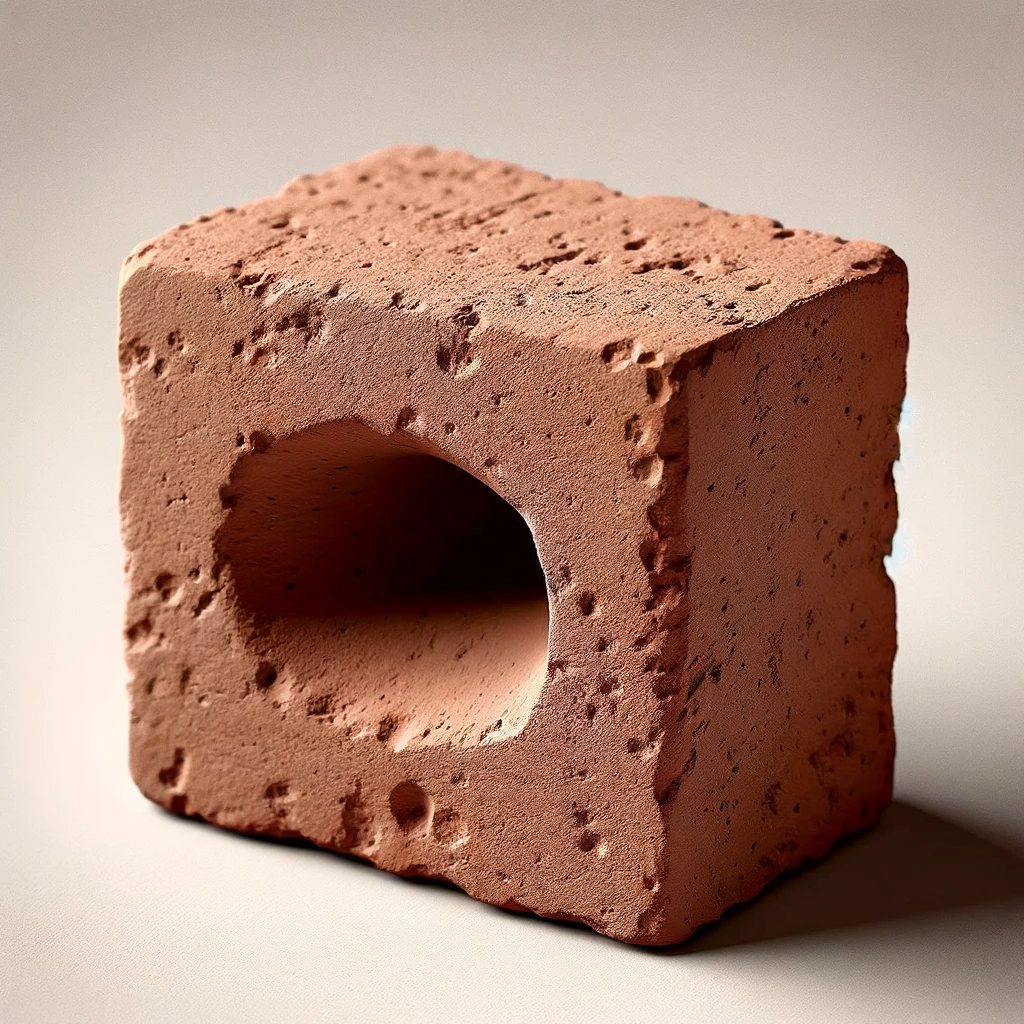

Definition of a Brick Frog

A frog in a brick refers to an indentation or depression on one of the longer faces of the brick. This indent is created during the manufacturing process and serves several important purposes in construction.

Why Frogs Are Used in Bricks

- Weight Reduction: The frog reduces the overall weight of the brick, making it easier to handle and transport.

- Better Bonding: The indentation provides a key into which mortar can flow, establishing a better mechanical bond between bricks.

- Strength and Stability: The mortar-filled frog ensures that bricks are more firmly secured, adding to the stability of the structure.

Structure of a Frog

| Component | Description |

|---|---|

| Depth | The indent is typically about 10-20mm deep, depending on the brick’s size and type. |

| Shape | Commonly rectangular or trapezoidal, aligning with the shape of the brick for uniformity. |

| Location | Usually found on the bed face, the horizontal face where the brick rests. |

Types of Bricks with Frogs

- Clay Bricks: Most often found in traditional clay bricks where the clay is pressed into molds with a protrusion to form the frog.

- Engineered Bricks: Some engineered bricks may feature a frog if designed for specific structural purposes.

Manufacturing Process of Frog Bricks

Description of Manufacturing Process

Creating the frog in a brick involves an extra step during production. Typically, the process starts by shaping the clay into rectangular prisms using a molding process. A protruding feature within the mold, or an additional tool, is utilized to create the depression in the brick’s bed face, forming the frog.

Impressed Frogs versus Extruded Frog Bricks

The method of creating the frog indentation can vary, mainly falling into two methods: impressing and extruding.

- Impressed: This traditional method involves pressing a protrusion into the brick’s face while it’s still in the mold, creating a clearer, more defined frog.

- Extruded: Modern brick factories often use extrusion machines. The frog is formed during the extrusion process by removing clay in a specific pattern to form an indentation, resulting in a less defined frog.

Guidelines for Using Frog Bricks

Mortar Application

When employing frog bricks in construction, it’s important that the frog is fully filled with mortar. This ensures the best possible adhesion between the bricks and enhances the structure’s overall strength and stability.

Frog Orientation

For construction purposes, it’s generally recommended that the frog be laid facing upwards. This positioning allows the mortar to fill the frog more effectively, contributing to a stronger bond between the bricks.

Frog Brick Limitations

While frog bricks have several benefits, they also have limitations. For instance, their use might not be advisable in conditions where bricks are likely to remain wet for extended periods. Due to their depressions, frog bricks can collect and hold water, which might lead to water-related damage over time.

Importance of the Frog Size

Influence on Brick Performance

The size of the frog can significantly impact the performance of the brick, particularly in relation to its weight and structural properties. For instance, a larger frog can cause the brick to weigh less but potentially compromise its load-bearing capacity.

Regulation of Frog Sizes

Different regions or countries might have regulations in place that prescribe the maximum and minimum frog sizes in bricks. This is largely to ensure the consistency and quality of the construction.

Further Reading

For more on the topic, consider this in-depth article from Construction Specifier which covers the complex science of brickworks and addresses many brick-related questions. It’s a brilliant starting point for those interested in the craft.

Scientific Considerations in Frog Bricks

Thermal Insulation Properties

The presence of a frog can enhance the thermal properties of a brick. The indentation can trap air, which acts as an insulator. This can be particularly beneficial in maintaining energy efficiency within buildings.

Water Absorption and Damp Proofing

Another aspect to consider is water absorption. While frog bricks offer better interlocking thanks to the mortar-filled indentation, they may also pose a risk by holding water. This can be mitigated by using proper damp-proofing techniques during construction to protect the bricks from prolonged exposure to moisture.

Environmental Impact and Sustainability

Material Efficiency

Frogs allow for a reduction in the amount of raw material needed per brick, which can contribute to more sustainable construction practices. Less clay means fewer raw materials are extracted, which can have positive environmental implications.

Energy Consumption

The reduction in raw materials consequently decreases the energy required for firing bricks. This is because a lighter brick will require less energy to bake fully, making the manufacturing process more energy-efficient.

Exploring the Necessity of Frogs in Bricks

Do All Bricks Need Frogs?

Not all bricks have or need frogs. The use of frogs in bricks largely depends on regional construction practices, the type of brick being used, and specific structural requirements.

Types of Bricks Without Frogs

- Engineering Bricks: These high-density bricks often do not have frogs, particularly because their primary use is for foundational purposes where high strength and low water absorption are essential.

- Concrete Bricks: Often used for decorative or load-bearing walls, concrete bricks typically don’t have frogs. They are manufactured using a different process and materials, which do not necessitate the inclusion of a frog.

- Extruded Bricks: Some extruded bricks, also known as wire-cut bricks, are produced without frogs. The extrusion process allows for more uniformity without the need for indentations.

Advantages of Bricks Without Frogs

| Aspect | Advantage |

|---|---|

| Uniformity | Smoother, more consistent surfaces contribute to aesthetic appeal and ease of handling. |

| Moisture Resistance | Lower risk of water retention and damage, making them ideal for certain environments. |

| Strength | Often stronger due to the absence of cavities that can compromise structural integrity. |

Considerations When Choosing Frog or Frogless Bricks

Structural Requirements

– Load-Bearing Walls: Higher strength and compressive resistance are often needed, which can be delivered by either frog or frogless bricks, depending on the specific engineering needs.

Climate Conditions

– Wet Climates: In environments prone to moisture, frogless bricks might be more suitable to avoid water retention and related damage.

Building Codes and Regulations

– Local Standards: Compliance with local construction standards is essential, as regulations may dictate the type of brick based on regional climatic conditions and typical building practices (source: Archtoolbox).

Practical Takeaways for Builders

– Material Selection: Considering the environment, structural demands, and local building codes are crucial in deciding whether to use bricks with or without frogs.

– Mortar Application: Ensure correct mortar application based on the brick type. For frog bricks, fill the frog completely for optimal stability.

Frog and frogless bricks each have unique advantages and are suitable for different applications. Making informed decisions about brick type can significantly impact the longevity and durability of construction projects.

For more detailed construction insights, visit Construction Specifier.

Wrapping Up the World of Frog Bricks

The presence of a frog in a brick is neither arbitrary nor a mere characteristic for aesthetics. On the contrary, it serves significant roles ranging from weight reduction, improved bonding, heightened structural stability to enhanced thermal insulation.

Beyond its functional aspects, it also contributes to sustainability and energy efficiency due to the reduction of raw materials needed. This underscores the continuous strive towards more sustainable construction practices.

However, it’s wise to remember that frog bricks are not universally suitable.

While they hold many advantages, their use is dependent on specific stonework requirements and environmental factors. For example, in areas prone to prolonged damp conditions, frogless bricks could be a more suitable choice.

Ultimately, understanding the benefits and limitations of different types of bricks ensures the correct application in different construction scenarios, contributing to more durable and sustainable buildings.

Frequently Asked Questions – FAQs

What is a frog in a brick?

A frog in a brick is an indentation or depression on one of the brick’s longer faces, created during manufacturing. It enhances the bond between bricks, reduces weight, and contributes to the structure’s stability.

Should the frog in a brick face upwards or downwards?

It is generally recommended to lay the frog facing upwards. This allows for the effective filling of mortar, creating a stronger bond between the bricks.

Why are some bricks without frogs?

The use of frogs in bricks depends on regional construction practices, the brick type, and specific structural requirements. Some bricks, such as engineered or extruded, can be manufactured without frogs.

Do frogs in bricks have any environmental implications?

Yes, frogs allow for reduction in raw materials used per brick and decrease energy consumption for firing bricks, contributing to more sustainable and energy-efficient manufacturing.

Are frog bricks stronger than frogless ones?

The strength depends on the specific application and construction requirements. Both types have unique advantages and can deliver optimal stability when used correctly.