Snap Ties for Concrete: A Construction Essential

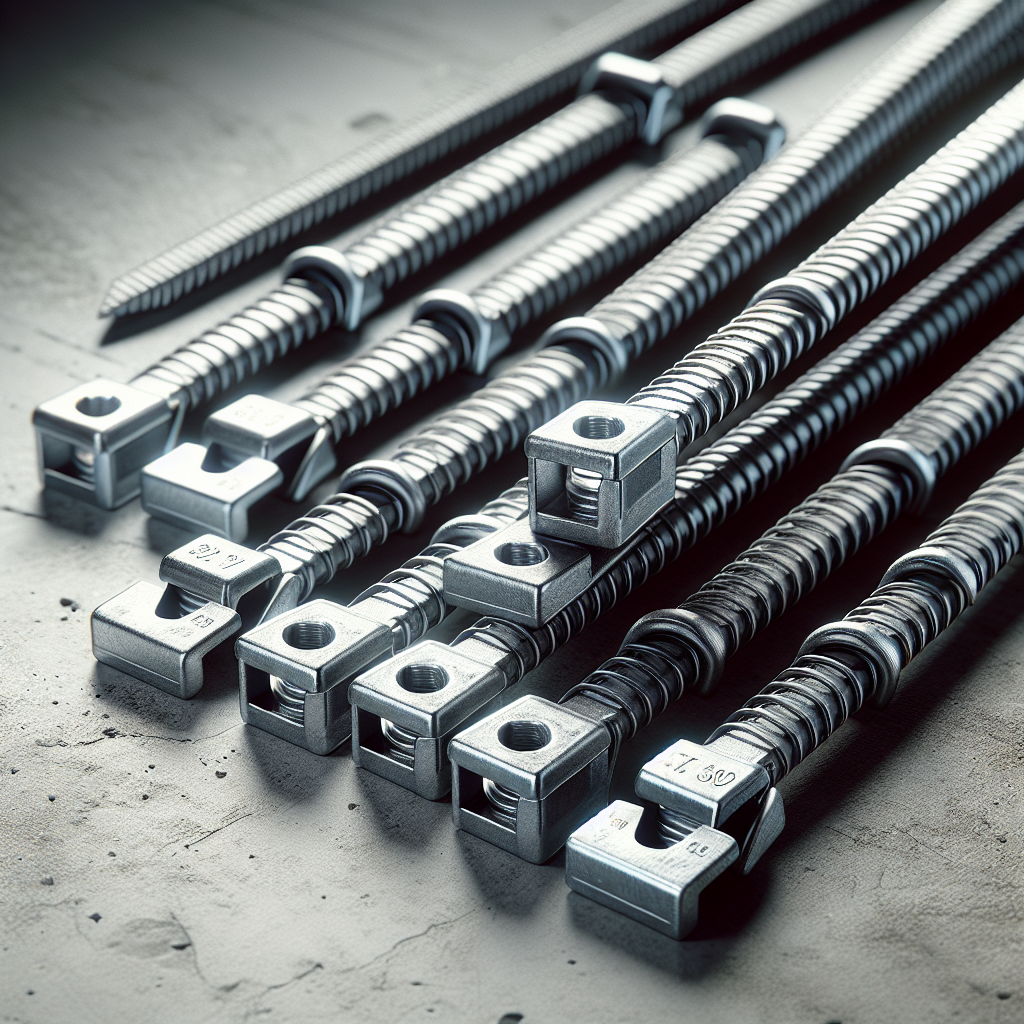

Snap ties are versatile tools used in the construction world. They function as critical parts of formwork systems, specifically for concrete structures.

Comprised of durable materials like steel, snap ties handle the immense pressure of wet concrete. Their role is to resist the lateral pressure of the fluid mix, ensuring the formwork stays intact during the curing process.

Thus, through using snap ties, builders achieve precision and stability in creating concrete structures, paving the path for safer and more reliable construction process.

Let’s jump into things and learn more about snap ties!

Table of Contents

What is the spacing for snap ties on concrete?

In the world of construction, understanding terminology is vital to productivity and safety. A term often used in concrete form assembly is “snap ties,” a crucial component that assists in keeping the concrete form intact before it hardens. The spacing annotation associated with snap ties is as essential, it determines their efficiency in holding the formwork.

Defining Snap Ties

In concrete installation, snap ties are non-reusable, small metal rods that are positioned across the inside of the concrete form where they maintain the form’s distance and integrity. One end is a loop (inner tie rod) and the other a break-off metal bar. They’re designed to hold the weight of wet concrete and when it has cured, the protruding end is “snapped off” hence the term “snap ties”.

Importance of Proper Snap Tie Spacing

The placement or spacing of these ties is crucial to the strength and stability of the formwork. The correct spacing helps in preventing form failure, ensuring that the concrete wall is thick enough and preventing leaks

What is the standard spacing for snap ties on concrete forms?

To distribute the load evenly on concrete forms, proper spacing of snap ties is essential. Standard guidelines recommend that snap ties be spaced at 12-24inches apart vertically and 18-36 inches horizontally with due consideration to the concrete’s pressure, wall thickness, and plywood thickness.

| Formwork Size conditions | Vertical Spacing | Horizontal Spacing |

|---|---|---|

| Light residential work | 24 inches | 36 inches |

| Commercial/Industrial work | 12 inches | 18 inches |

Concluding Note

Choosing the right snap tie spacing for concrete forms is a matter of safety and quality of work. Too much space between ties can lead to form blowouts, while too little can lead to wasted resources and undue pressure on the ties. Therefore, a proper understanding of the functionality, use, and spacing of snap ties is essential in building durable and safe concrete structures.

Sources:

Snap Ties in Concrete Formwork: Construction Management Guide

The Balance SMB, Spacing for concrete ties

How Much Pressure Can a Snap Tie Hold?

Given the critical role snap ties play in concrete construction, understanding the amount of pressure they can withstand is just as crucial as spacing. Most construction mishaps result from an inability to correlate the pressure of wet concrete with the capacity of snap ties, leading to issues like formwork failure. Despite the versatile applications of snap ties, their ability to support pressure mainly relies on material quality, design, spacing, and the pressure of the wet concrete.

Material Quality

Snap ties are typically made of high-strength steel, a material known for its durability and resilience. This inherent robustness enables snap ties to withstand the pressure exerted by the weight of wet concrete. However, like any construction equipment, snap ties’ load-bearing capacity is contingent on their quality. High-quality, well-manufactured snap ties can endure much more pressure than their lower quality counterparts.

Snap Tie Design

The design of snap ties also plays a part in determining how much pressure they can handle. Standard snap ties are designed with a 1″ diameter bend on each end, facilitating a 2-1/8″ break-back. This design allows the ties to withstand significant lateral pressure from the wet concrete, ensuring the formwork remains intact until the concrete is entirely cured.

Snap Tie Pressure Ratings

On average, a standard snap tie can handle lateral pressure up to 2,250 lbs. However, snap ties with stronger design characteristics and superior material quality can cope with an enhanced load —up to 4,500 lbs of lateral pressure. For such cases, it is crucial to remember that accommodating the higher load requires the use of stronger coil ties, stronger waler bars, and more rigid plywood.

How Snap Tie Spacing Impacts Pressure Capacity

Spacing directly influences the overall pressure a snap tie can support. The closer the ties, the more evenly distributed the concrete pressure, allowing for more significant pressure handling. Conversely, snap ties spaced further apart have to bear more load individually, thereby reducing each tie’s pressure-handling capacity.

In Summary

To ensure safe and efficient formwork construction, understanding the load-bearing capacity of snap ties is crucial. This knowledge helps in deciding the type and spacing of snap ties, allowing you to optimally balance the pressure distribution and stability of construction.

Sources:

Builderbill, Concrete Footings and Foundations

Western Forms, Snap Tie Setting and Bracing

Understanding the Snap Off Process

A critical component of using snap ties in concrete formwork is knowing how to properly break them off once the concrete has hardened. This process ensures a clean, flush finished surface and the complete removal of excess snap tie material.

When to Break Off Snap Ties

Deciding when to break off the snap ties is largely dependent on the state of the concrete. Typically, snap ties should be removed 24 hours after the pour, when the concrete has hardened but not fully cured. It is at this point the concrete is still soft enough to allow for a clean break without cracking or damaging the surrounding surface.

The Snap-Off Process

The removal of the snap ties is done manually using a specialized prying tool or hammer. The tool is positioned at the small gap where the tie meets the concrete surface. A sharp force is then applied to ‘snap’ off the outer bar end. The unique design of snap ties includes a predetermined break point, which ensures a clean break without leaving any metal exposed on the finished concrete surface.

Guidelines to Break Snap Ties

- Never attempt to break off snap ties when the concrete is still wet. This can lead to cracks or fissures in the concrete, compromising its structural integrity.

- Use a specialized prying tool or hammer to ensure a clean break. Using a wrong tool can result in damage to the concrete.

- Wear protective gear such as safety gloves and glasses during the process to protect against potential flying debris.

Post Snap-Off Considerations

Once the snap ties have been removed, it is essential to patch the resulting holes with a high-quality epoxy or polymer-modified cement patch to maintain the wall’s waterproof integrity and aesthetic appeal.

Concluding Remarks

A solid understanding of how to properly break off snap ties after concrete has set significantly affects the overall quality and finish of your concrete work. This process prevents potential damage to the concrete and helps maintain its structural integrity.

Sources:

WOC360 – How to remove snap ties and form work

Durham Geo – Concrete Snap Ties and Forms FAQ

Conclusion

In the context of our exploration of snap ties and their essentiality in constructing concrete forms, we’ve found that proper spacing is a critical aspect. This standard, ranging from 12-24 inches apart vertically and 18-36 inches horizontally, mirrors the necessity for balance in maintaining formwork’s integrity and the efficiency of resource use.

From our perspective, a clear understanding of snap ties’ function, utilization, and spacing becomes an imperative for anyone involved in concrete construction. Adopting these standards aids in avoiding form blowouts and unnecessary resource expenditure while securing the longevity and safety of our concrete structures. So while concrete may serve as the foundation of our buildings, knowledge, and proper application of elements like snap ties are the cornerstones of robust and lasting construction.