Air-Entraining Concrete: A Key Ally in Construction

Think of air-entraining concrete as a builder’s best friend.

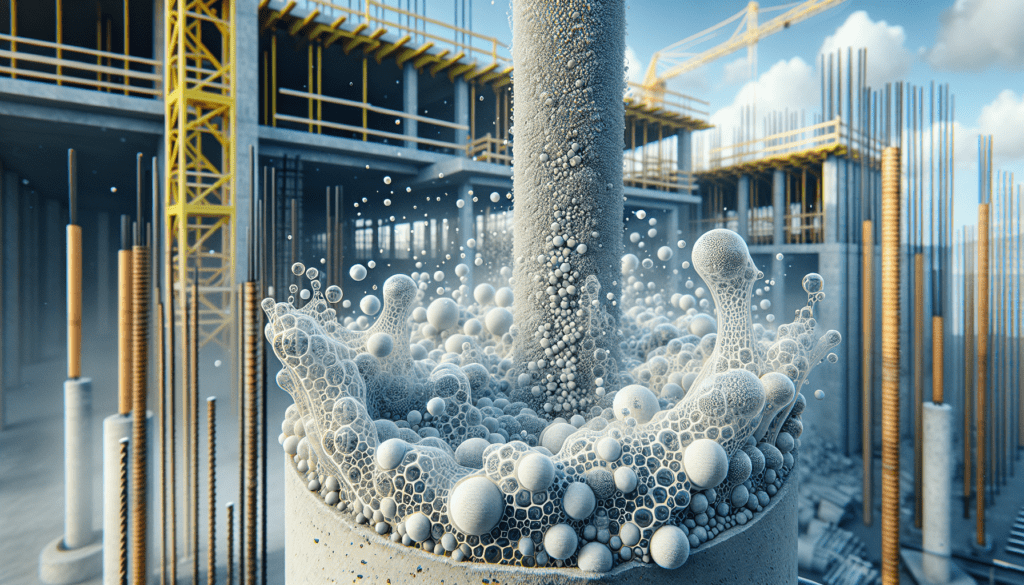

In essence, it is a type of concrete that contains billions of microscopic air cells.

These tiny air pockets serve a critical role. They offer a buffer, preventing stress and fracture when the material undergoes changes in volume due to variations in temperature.

In the realm of construction, the usage of air-entraining concrete has practical implications. Its inherent damage resistance enhances the durability of structures, making it particularly useful in environments where temperature fluctuates drastically.

Table of Contents

Understanding Air-Entraining Concrete

When thinking about construction materials, air-entraining concrete may not be the first that comes to mind, but it’s an important player in the industry. Designed specifically for freeze-thaw conditions, this unique type of concrete offers key advantages in the construction world.

What is Air-Entraining Concrete?

Beginning our exploration into the makeup of air-entraining concrete, it’s crucial to first understand what sets it apart from its counterparts.

Definition

Air-entraining concrete is a special type of concrete that is mixed with air-entraining admixtures. These admixtures introduce millions of microscopic air cells into the mix, which provide space for water to expand when it freezes. This helps to prevent cracking and damage caused by frost-heave cycles in colder environments.

How is Air-Entraining Concrete Mixed?

Mixing air-entraining concrete involves an artful balance of ingredients and technique to achieve the ideal result. Here’s a detailed breakdown of the process:

1. Ingredient Collection

- Portland cement

- Aggregate (such as sand, gravel, or crushed stones)

- Water

- Air-entraining admixtures

2. Mixing Process

| Stage | Description |

|---|---|

| Initial Mixing | The Portland cement, aggregate, and water are first mixed together in a concrete mixer. |

| Addition of Admixture | The air-entraining admixture is introduced to the mix. This is commonly in a liquid form and added during the water addition stage to ensure even distribution. |

| Final Mixing | The concrete mix is further mixed to ensure that the admixture is well distributed throughout. This creates a vast number of small air pockets within the concrete. |

In conclusion, air-entraining concrete is a construction material made with precision and technical knowledge. By introducing man-made air cells to a cement mix, it brings resilience and durability to structures, especially in regions subject to freeze-thaw cycles. [1]

The Cost of Using Air-Entraining Concrete In A Construction Project

Benefits of Using Air-Entraining Concrete

- It increases resistance to freeze-thaw cycles and chemical attacks.

- Promotes longevity and durability of the structure.

- Improves workability of the mixture, reducing construction effort and time.

Now that we have a basic understanding of air-entraining concrete, let’s consider the cost implications of its use.

Cost of Air-Entraining Concrete

It’s important to note that the cost of using air-entraining concrete can depend on several factors such as the project size, location, supplier, and current market conditions. While it’s challenging to pinpoint an exact figure without these details, generally, air-entraining concrete tends to cost more than regular concrete.

Factors Affecting Air-Entraining Concrete Cost

- Project size: As expected, larger projects will require more material, hence a higher cost.

- Location: Costs might differ based on the location of your project due to transportation and logistics expenses.

- Supplier: Different suppliers will offer different prices based on their sourcing, production, and operational costs.

- Market conditions: Market fluctuations can significantly affect pricing.

For an exact figure, it’s recommended to always consult with an experienced contractor or supplier who can provide a quote based on your project’s specific needs.

Is Air-Entraining Concrete Worth the Extra Cost?

Despite the additional expense, the numerous benefits associated with air-entraining concrete make it a worthwhile investment for most projects. By increasing durability and decreasing maintenance costs, this type of concrete can lead to savings in the long run. However, the final decision always depends on your project’s specific requirements and budget constraints.

Disadvantages of Air-Entraining Concrete

Disadvantages of Air-Entraining Concrete

Henceforth, we will elaborate on some of the downsides related to the use of air-entraining concrete.

1. Lowered strength

On the top of the list of the disadvantages of air-entraining concrete is a compromised compressive strength. The fine air voids increase the porousness of the concrete substance, therefore reducing its overall strength [source](https://civilblog.org/2015/03/05/advantages-and-disadvantages-of-air-entrained-concrete/).

2. Difficulty in application

Another potential disadvantage could be the complexity of the application process. Ensuring the correct and uniform distribution of air voids requires a level of specialty that could cause difficulty for untrained constructors.

3. Increased cost

Introducing air entrainment in concrete may also drive up the cost as it requires specific materials and techniques to incorporate the air voids properly.

Here’s a brief overview of the aforementioned points:

| Disadvantage | Description |

|---|---|

| Lowered strength | Increased porousness caused by the fine air voids reduces overall strength. |

| Difficulty in application | Introducing air voids uniformly requires a level of expertise, making the procedure complex for unexperienced handlers. |

| Increased cost | Materials and techniques necessary for air-entraining may contribute to increased cost. |

While air-entraining concrete does offer significant advantages, such as increased durability and resistance to freeze-thaw cycles, consideration must be taken into account regarding its downsides.

Understanding these disadvantages aids in choosing the right type of concrete for specific construction projects to ensure efficiency and effectiveness.

Ultimately, the choice will depend on the project’s requirements, the environment, and cost considerations.

Conclusion On Concrete

From our exploration, we’ve found that air-entraining concrete is a vital asset in the construction field, especially in freeze-thaw climates. It demonstrates the power of clever engineering in overcoming natural obstacles to durability.

By using specific admixtures, it incorporates millions of tiny air cells that allow water expansion, cleverly preventing potential frost-heave damage and cracks.

In our experience, creating this formidable building material involves a keen sense of balance in mixing just the right ingredients, with the introduction of air-entraining admixtures playing a critical role in its functionality. In essence, the resilience and longevity offered by air-entraining concrete make it a product of innovative construction approaches shaping our built environment.