Tell Me A little More About Sticky Concrete

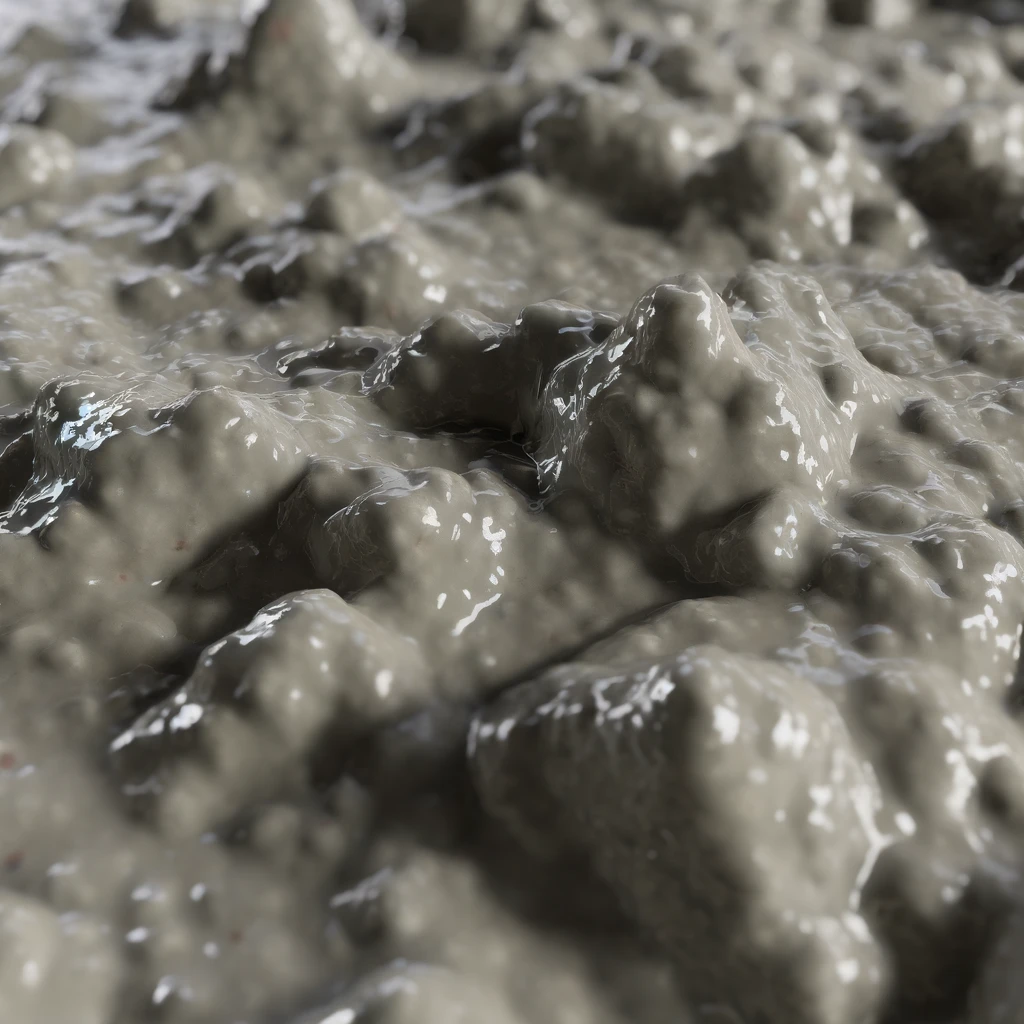

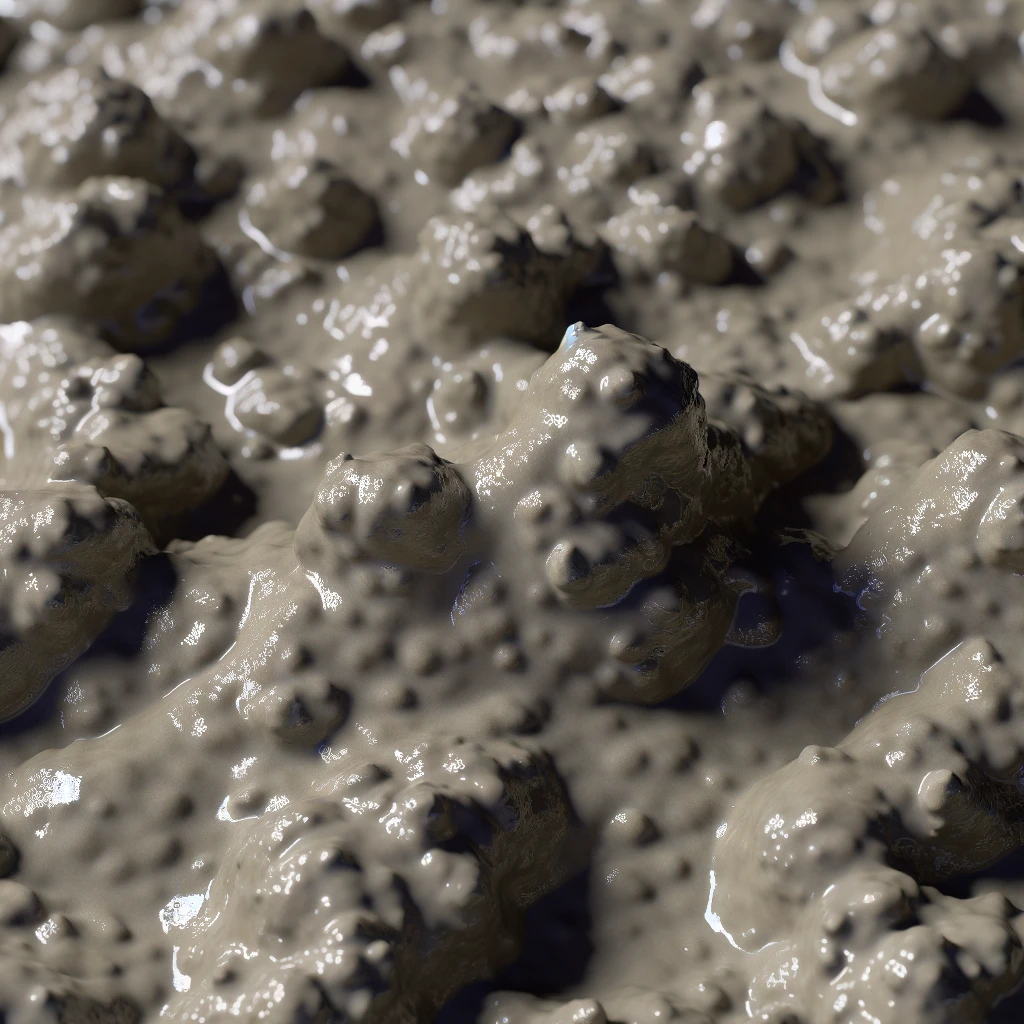

Sticky concrete refers to a specific consistency of concrete mix that is harder to work with due to its high adhesive quality.

This state can be challenging as it adheres to tools and surfaces, causing difficulty in a construction setting. Although it requires precise handling, its sticking property can also act as an advantage in ensuring stronger bonds and sturdy construction.

So, while dealing with sticky concrete may require an added layer of expertise, it plays a unique and crucial role in construction and infrastructure building.

Table of Contents

Now Let’s Dive into Sticky Concrete

Concrete is a vital component in the construction field, and its state can greatly impact a project’s success. One often misunderstood phenomenon is when concrete turns sticky. So, what causes concrete to be sticky, and how can we address it?

The Composition of Concrete

Before diving into the stickiness issue, let’s understand the foundational ingredients in concrete.

- Cement

- Aggregate: large and fine mixture (like gravel and sand)

- Water

- Air

The ratio of these components determines concrete’s properties, including its stickiness or workability.

What Makes Concrete Sticky?

Now that we know what’s in our “cake mix,” let’s delve into the primary culprit behind sticky concrete: an excessively high water-cement ratio.

Water-Cement Ratio and Stickiness

When the water-cement ratio in a concrete mix is off, it can result in sticky concrete. A mix with too much water makes concrete overly fluid and weak. Conversely, a mix with too little water makes the concrete unworkable and sticky. It becomes difficult to pour, spread, and can negatively impact the finish.

A perfect ratio of water to cement is paramount for workable, strong, and durable concrete. This is typically around 0.45 to 0.60. A higher ratio might seem to make the mix more workable, but it actually compromises its strength, while a lower ratio results in sticky and unmanageable concrete.

High Fines Content

Another contributing factor to the stickiness of concrete is the fines content. “Fines” refer to fine aggregates like sand used in the mix. An excess of such fines makes concrete sticky and harder to work with.

Addressing Sticky Concrete

To handle sticky concrete effectively:

- Measure carefully: Ensure that all materials are measured accurately to maintain the correct ratio.

- Reduce fines: If needed, reduce the amount of fine aggregate in your mix.

- Add a plasticizer: These can increase the workability of the concrete without having to add additional water.

| Problem | Solution |

|---|---|

| Excessively high water-cement ratio. | Maintain a balance in your water-cement ratio, ideally between 0.45 to 0.60. |

| High fines content | Reduce the amount of fine aggregate used in the mix. |

| Sticky and unworkable concrete | Consider using a concrete plasticizer to increase workability without adding extra water. |

In conclusion, understanding the factors influencing the workability of concrete will empower you to diagnose the root cause of sticky concrete and approach its resolution effectively. Don’t forget, a well-balanced concrete mix is key to a successful construction project.

Detecting and Assessing Faulty Concrete Slabs

Continuing from understanding sticky concrete, let’s now move towards identifying if a concrete slab is bad. A concrete slab’s integrity is essential in any structure as substandard concrete slabs can bring about significant issues that can affect the safety and stability of a building.

Signs of a Damaged Concrete Slab

To assess whether a slab is bad, several telltale signs indicate concrete defects or deterioration.

Cracks

One common sign of a bad concrete slab is visible cracks. Superficial cracks may not threaten the overall structure; however, larger and deep-set structural cracks can be problematic. Cracks can occur due to various reasons like overloading, thermal expansion and contraction, subgrade settlement, or the natural aging of the concrete.

Surface Discoloration

Uneven color or surface discoloration is another sign to watch out for. It can be an indication of inconsistent mixing and application of the slab.

Uneven Surface or Structural Deformation

Concrete slabs should provide a level surface. If you notice unevenness, buckling, or warping, this might point to fundamental issues with the slab. This could be due to poor installation, settlement, or the use of inferior materials.

How to Assess a Concrete Slab’s Quality

When suspecting that a concrete slab might be defective, take the necessary steps to confirm your assumptions and evaluate the severity of the issues.

Visual Inspection

Initially, a simple visual inspection can provide valuable cues. Look for cracks, discoloration, and overall deformation of the slab.

Use of Structural Engineers

Professional opinion is invaluable, especially when dealing with potential structural issues. Qualified structural engineers can perform thorough inspections, diagnose issues accurately, and propose optimal solutions.

Concrete Testing

Additionally, specialized labs can test core samples from the slab. They can analyze the concrete’s compressive strength, the water-cement ratio, and the content and type of aggregates, which can give precious insights into the potential problems of the slab.

In conclusion, recognizing the state of a concrete slab is essential. Detecting and addressing issues promptly can avoid more severe consequences like structural instability or failure. It’s recommended to consult professionals and follow specified standards and guidelines provided by construction authority in your locality.

For a comprehensive guide on concrete durability checks, you can refer to the American Concrete Institute’s manual which provides a summary of code provisions for durability.

Manipulating Concrete Properties: Stickiness and Workability

Expanding on our discussion on concrete, let’s shift focus to how one can purposefully alter concrete’s properties to make it sticky or modify its workability. Potential modifications may significantly impact a project’s outcomes and efficiency.

Adjusting Water-Cement Ratio

As discussed earlier, altering the water-cement ratio directly affects the stickiness and workability of the concrete mix. Provisioning slightly more water than the ideal ratio can increase fluidity, making the concrete easier to handle and form.

The Role of Hydration

Water in the mix initiates a process called hydration, wherein it reacts with cement to form a stiff and hardened structure. Keeping a well-balanced ratio is essential because too much water can weaken the final product, while superfluous cement will leave unhydrated particles leading to potential stickiness.

Manipulating Aggregate Size and Shape

The choice and mix of aggregate can also affect the stickiness and workability of concrete. Larger aggregates tend to decrease stickiness and increase workability. Additionally, angular-shaped aggregates can interlock better than rounded ones, leading to a stronger yet less workable mix.

Use of Admixtures

In situations where traditional mix strategies can’t achieve the desired consistency, concrete admixtures become crucial. Using admixtures, concrete’s workability can be improved without altering strength.

Superplasticizers

Superplasticizers are types of admixtures that can improve workability exponentially by dispersing cement particles. This reduces friction between particles and water, making the concrete less sticky and easy to work with.

Air-Entraining Agents

Air-entraining agents create small, uniform air bubbles within the concrete mix. This increases workability and reduces stickiness, while also improving durability in the face of freeze-thaw cycles.

Effectively Mixing Concrete

Lastly, the manner of mixing also influences stickiness and workability. Proper, thorough mixing ensures equal distribution of water and other particles, leading to uniform consistency and reducing stickiness chances.

| Concrete Property | Change | Techniques |

|---|---|---|

| Stickiness | Decreased | Optimized water-cement ratio, use of larger aggregates, incorporation of admixtures, thorough mixing |

| Workability | Increased | Optimized water-cement ratio, use of rounded aggregates, incorporation of superplasticizers and air-entraining agents, thorough mixing |

In conclusion, manipulating concrete’s properties to achieve the desired stickiness and workability involves careful balance and expertise. With careful attention to the ingredients’ proportion, aggregate choice, the use of admixtures, and efficient mixing, concrete’s properties can be adequately adjusted.

Solidifying Our Understanding of Sticky Concrete

In sum, we’ve found that the intricate balance of its components plays a significant role. Factors such as an excessively high water-cement ratio and a high fines content can result in this pesky concrete condition. From our perspective, skillfully addressing these issues involves careful measurement of the material quantities, a reduction in fine aggregates if necessary, and the clever use of a concrete plasticizer.

As we wrap up, let’s not underestimate the significance of a well-balanced concrete mix. It’s not only vital for crafting workable concrete but also forms the bedrock of any successful construction project. For those of you seeking a deeper dive into concrete nuances, the National Ready Mixed Concrete Association’s guide is a fantastic resource. Remember, each project is a new challenge, demanding its unique tweak and change. Here’s to your next construction endeavor!