Introduction To Abrams’ Law

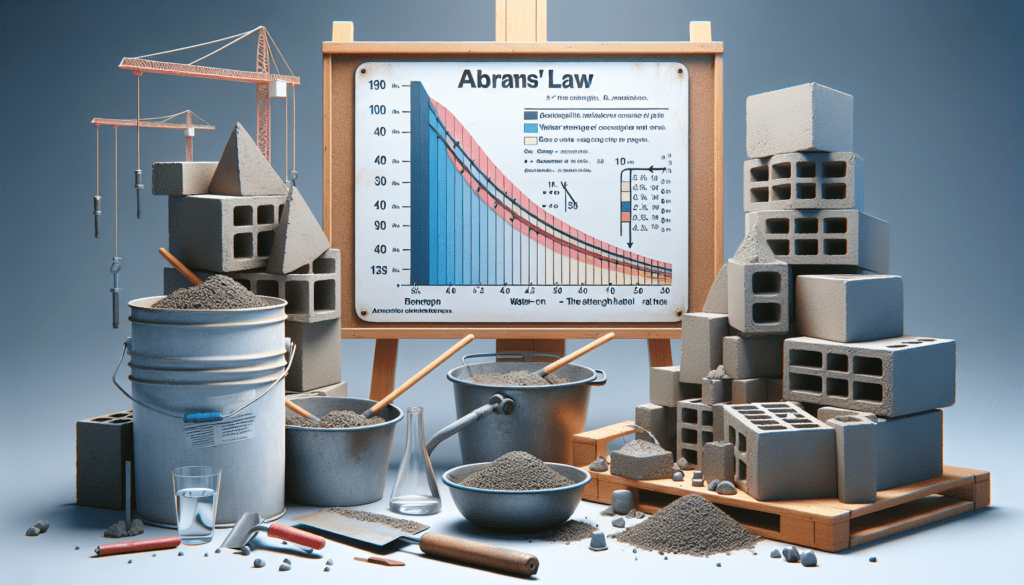

Abrams’ Law is a principle in civil engineering, specifically in concrete mix design. It denotes the inverse relationship between the water-cement ratio and the strength of the resulting mix.

This fundamental tenet impacts the quality and durability of many construction projects. Understanding and applying it ensures the best outcome in concrete related construction.

In simplified terms, it tells us that the lower the water-to-cement ratio, the stronger the concrete – crucial knowledge for both engineers and builders.

Time to turn the mixer on and dive in.

Let’s get started.

Table of Contents

Historical Context of Abrams’ Law

Origins of Abrams’ Law

Abrams’ Law, formulated by Duff A. Abrams in the early 1910s, emerged from extensive research into concrete mix designs. At the time, there was a pressing need to establish reliable methods for predicting the strength and durability of concrete, which was increasingly being used in various construction projects.

- Research and Experiments: Duff A. Abrams conducted numerous experiments to investigate the relationship between the water-cement ratio and the strength of concrete. His findings highlighted a clear inverse correlation, leading to the formulation of Abrams’ Law.

- Publication and Acceptance: Abrams’ research was published and widely accepted by the civil engineering community, marking a significant milestone in concrete technology. His work provided a scientific basis for optimizing concrete mix designs, which had previously been based on empirical methods and trial-and-error.

Evolution and Modern Applications

Over the decades, Abrams’ Law has been refined and adapted to suit the evolving needs of the construction industry. Here are some key developments:

- Advancements in Materials: With the introduction of new cement types, admixtures, and supplementary cementitious materials, the application of Abrams’ Law has expanded. Modern concrete technology leverages these advancements to achieve even higher performance characteristics.

- Quality Control Techniques: The principles of Abrams’ Law have been integrated into advanced quality control techniques. This includes sophisticated mix design software and real-time monitoring systems that ensure precise water-cement ratios during concrete production.

- Sustainability Considerations: In contemporary construction, there is a growing emphasis on sustainability. Abrams’ Law plays a crucial role in this context by promoting efficient use of materials and reducing waste. Optimizing the water-cement ratio contributes to lower carbon emissions associated with cement production and enhances the durability of structures, thereby extending their service life.

Impact on Standards and Regulations

Abrams’ Law has significantly influenced building codes, standards, and regulations worldwide. Many construction standards incorporate guidelines based on Abrams’ Law to ensure the quality and reliability of concrete structures.

- Building Codes: National and international building codes often specify maximum permissible water-cement ratios for different types of concrete applications. These specifications help ensure that concrete mixes meet the required strength and durability criteria.

- Industry Standards: Organizations such as the American Concrete Institute (ACI) and ASTM International have developed standards and testing methods that align with the principles of Abrams’ Law. These standards provide a benchmark for the construction industry to follow, ensuring consistency and quality across projects.

Abrams’ Law, with its historical roots and ongoing relevance, remains a cornerstone of concrete mix design and construction practices. The integration of Abrams’ Law into modern construction not only enhances the strength and durability of concrete structures but also contributes to more sustainable and cost-efficient building practices.

The Magic of Abrams’ Law

How Does Abrams’ Law Affect Costs?

It might not be immediately obvious how a law related to concrete strength can lead to cost savings. The secret lies within the quality of the final product and the implications for project longevity and maintenance costs.

Let’s break it down:

- Increased Durability: By careful adherence to Abrams’ Law, construction teams can create a denser, stronger concrete. This increase in quality can significantly extend the lifespan of structures, reducing the total lifecycle cost of construction projects and possible replacement costs.

- Reduced Maintenance: Stronger concrete structures are likely to suffer less from typical stresses that can lead to damage and costly repairs, such as freeze-thaw cycles or load-bearing demands.

- Savings On Materials: Following Abrams’ Law can lead to savings on materials too. By optimizing the water-to-cement ratio, contractors can avoid wastage and reduce the amount of cement needed, which can be a significant cost in large-scale construction projects.

Applying Abrams’ Law For Cost Saving: A Practical Example

Let’s look at how applying Abrams’ Law can lead to cost savings in the real world, taking the construction of an office building as an example.

| Without Abrams’ Law | With Abrams’ Law |

|---|---|

| The concrete mix is inconsistent. This results in varying strength and durability, leading to repairs and replacements within 5-10 years. | The concrete mix is optimized. The building lasts 20+ years without major structural repairs. |

| Regular maintenance is necessary due to concrete damage from environmental and load-bearing stresses. High cost of frequent maintenance activities. | Minimal maintenance is required due to the increased strength and durability of the concrete. Significant savings on maintenance costs. |

| More cement is used in the attempt to compensate for the increased water content. Higher construction and material costs. | Optimized water-to-cement ratio reduces the amount of cement needed. Material cost savings on the construction. |

By applying Abrams’ Law effectively in construction projects, it’s possible to create higher quality concrete structures that can withstand the test of time, thereby reducing long-term costs.

It’s another reminder of how an understanding of the scientific principles behind construction can lead to improved efficiency and significant savings.

Using Abrams’ Law During Construction

Decisions about Concrete Mix

Abrams’ law can influence decisions about the type of concrete mix used in property development. Consider the following:

- For structures requiring high strength, such as high-rise buildings, a low w/c ratio concrete mix will need to be used.

- Meanwhile, for structures that don’t require as much strength, a higher w/c ratio mix might suffice.

Cost Implications

Abrams’ Law can also impact the cost of property development, as follows:

- If a project calls for high-strength concrete, implying lower water to cement ratios, more cement would be needed, which may increase the project’s cost.

- Conversely, for projects that don’t require high-strength concrete, developers can save on costs by using mixes with higher water to cement ratios.

Longevity and Durability of the Property

Since the strength of concrete has a direct impact on the longevity and durability of a structure, Abrams’ Law indirectly affects these crucial aspects of property development. A building with appropriately strong concrete, as guided by the law, is likely to last longer and exhibit greater resistance to environmental degradation and wear.

The application of Abrams’ Law in property development goes beyond mere construction. It impacts a project’s cost, durability, and the longevity of constructed buildings.

By internalizing this law, developers can make more informed decisions, which can ultimately boost the success of their projects.

How To Calculate Abrams’ Law

Formula Of Abrams’ Law

The scientific formula of Abrams’s Law is as follows:

Strength ≈ k/(water-to-cement ratio)

“k” represents the specific strength potential of the mix deriving from its other components, like the quality of cement and the aggregates.

Importance of Understanding Abrams’ Law in Construction

Implementing Abrams’ Law in construction serves numerous purposes. Here are a few key reasons why understanding this principle is essential:

- Quality Control: By considering the water-cement ratio as outlined in Abrams’ Law, construction engineers can monitor and adjust the concrete’s strength, affect its durability, and improve the final project’s hardness.

- Cost Efficiency: A comprehension of Abrams’ Law can lead to more cost-efficient practices. By adjusting the water-cement ratio, construction teams can optimize material usage, reducing waste and saving costs.

- Improved Sustainability: Making the most out of materials contributes to green building practices. By increasing sustainability, builders not only improve their reputation but also contribute to global environment conservation efforts.

Practical Applications of Abrams’ Law

Construction professionals can apply Abrams’ Law in various ways, such as:

- Construction design reviews to determine if the concrete proposed will deliver the required strength.

- Quality control in concrete production by optimizing concrete mixtures and ensuring the appropriate water-cement ratio is applied.

- Evaluating project budgets by controlling the amount of cement used in construction projects and thereby reducing material costs.

Understanding Abrams’ Law and applying it to construction processes can significantly improve project outcomes. Whether for quality control, cost efficiency, or sustainability, this crucial principle plays a key role in the construction industry.

Through continuous learning and application of concepts like Abrams’ Law, construction professionals can improve their work while contributing to a more sustainable future.

Common Misconceptions About Abrams’ Law

Despite its fundamental importance in concrete technology, there are several misconceptions about Abrams’ Law that can lead to misapplications and misunderstandings. Here, we address some of these common misconceptions and provide clarifications to ensure accurate implementation.

Misconception 1: Lower Water-Cement Ratio Always Means Better Quality

While Abrams’ Law indicates that a lower water-cement ratio results in higher concrete strength, it is not always true that the lowest possible ratio will yield the best overall quality.

- Workability Issues: Extremely low water-cement ratios can make the concrete mix less workable, leading to difficulties in mixing, placing, and finishing. This can result in improper compaction and increased risk of voids and honeycombing.

- Durability Considerations: For certain applications, slightly higher water-cement ratios may be necessary to ensure adequate workability and durability. This is especially true for structures exposed to harsh environmental conditions, where proper compaction and curing are crucial for long-term performance.

Misconception 2: Abrams’ Law Only Applies to Strength

Abrams’ Law is often narrowly interpreted as relating solely to the compressive strength of concrete. However, its implications extend beyond strength alone.

- Durability and Permeability: The water-cement ratio also significantly affects the permeability and durability of concrete. Lower ratios reduce the porosity of concrete, thereby enhancing its resistance to water ingress, chemical attacks, and freeze-thaw cycles.

- Shrinkage and Cracking: The water-cement ratio influences drying shrinkage and the potential for cracking. Proper balance is essential to minimize shrinkage and control crack development.

Misconception 3: The Water-Cement Ratio is the Only Factor in Concrete Strength

While the water-cement ratio is a critical factor, it is not the sole determinant of concrete strength.

- Aggregate Quality: The type, size, and quality of aggregates used in the mix also play a vital role in determining the concrete’s strength and performance.

- Cement Type and Quality: Different types of cement and their specific properties can affect the strength and other characteristics of the concrete.

- Mix Proportions: The overall proportions of the mix, including the amount of cement, aggregates, and admixtures, must be carefully designed to achieve the desired properties.

Misconception 4: Abrams’ Law is Outdated

Some believe that Abrams’ Law is an outdated concept given modern advancements in concrete technology and materials.

- Continued Relevance: Despite technological advancements, the fundamental principles of Abrams’ Law remain highly relevant. Modern mix design methods and quality control techniques still rely on optimizing the water-cement ratio to achieve desired performance outcomes.

- Adaptation to New Materials: The principles of Abrams’ Law have been successfully adapted to accommodate new materials and admixtures, ensuring that it continues to provide a reliable basis for concrete mix design.

Misconception 5: Higher Cement Content Always Improves Strength

Increasing the cement content is sometimes seen as a straightforward way to boost concrete strength. However, this approach can be counterproductive.

- Heat of Hydration: Higher cement content can increase the heat of hydration, leading to thermal cracking, especially in mass concrete structures.

- Cost and Sustainability: Excessive cement use is costly and environmentally unsustainable. Optimizing the water-cement ratio allows for efficient use of cement while achieving the desired strength and durability.

Challenges and Limitations of Applying Abrams’ Law

While Abrams’ Law provides fundamental guidelines for optimizing concrete strength and quality, there are challenges and limitations associated with its application. Understanding these challenges is crucial for effective implementation and achieving the desired outcomes in concrete construction.

Variability in Materials

Inconsistent Cement Quality

The quality of cement can vary between different batches and suppliers, affecting the concrete mix’s performance.

- Quality Control: Ensuring consistent quality of cement requires rigorous quality control measures at both the production and construction sites.

- Supplier Reliability: Working with reliable suppliers who maintain high standards can mitigate issues related to cement variability.

Aggregate Properties

Aggregates, such as sand and gravel, also exhibit variability that can impact the concrete mix.

- Size and Shape: Variations in the size and shape of aggregates can affect the water demand and, consequently, the water-cement ratio.

- Cleanliness: Contaminants and impurities in aggregates can alter the mix’s properties, requiring adjustments to the water-cement ratio.

Environmental Factors

Temperature and Humidity

Environmental conditions during mixing, placing, and curing can significantly impact the effectiveness of Abrams’ Law.

- Temperature Effects: High temperatures can increase the rate of hydration, potentially leading to a higher water demand and affecting the water-cement ratio.

- Humidity Levels: Low humidity can accelerate the evaporation of water from the concrete mix, necessitating adjustments to maintain the desired water-cement ratio.

Weather Conditions

Weather conditions at the construction site can pose challenges to maintaining the optimal water-cement ratio.

- Rain and Moisture: Unexpected rain or high moisture levels can introduce additional water into the mix, compromising the desired ratio.

- Wind and Dryness: Windy conditions can cause rapid drying of the mix, requiring measures to retain moisture and maintain workability.

Practical Implementation

Workability Issues

Maintaining a low water-cement ratio can lead to workability challenges during mixing and placement.

- Mixing Challenges: A low water-cement ratio can make the concrete mix stiffer and harder to mix, requiring advanced mixing techniques or equipment.

- Placement and Finishing: Stiffer mixes can be more difficult to place and finish, potentially leading to issues like improper compaction and surface defects.

Construction Practices

Adhering to Abrams’ Law requires diligent attention to construction practices and on-site management.

- Consistency: Ensuring consistency in mix design and execution across different sections of a project can be challenging.

- Training and Supervision: Proper training for construction personnel and close supervision during mixing and placing are essential to maintain the desired water-cement ratio.

Technological and Equipment Limitations

Advanced Mixing Equipment

Implementing Abrams’ Law effectively may require advanced mixing equipment to ensure uniformity and precision.

- Equipment Availability: Access to modern and well-maintained mixing equipment is crucial for achieving consistent results.

- Cost Considerations: Investing in advanced equipment can be costly, particularly for smaller construction projects.

Real-Time Monitoring

Real-time monitoring of the water-cement ratio can enhance adherence to Abrams’ Law but may not always be feasible.

- Technology Integration: Integrating real-time monitoring systems into the construction process can be technically challenging and expensive.

- Data Accuracy: Ensuring the accuracy and reliability of real-time data is critical for making informed adjustments to the mix.

Conclusion On Abram’s Law

In conclusion, the application of Abrams’ Law is a game-changer in managing construction costs effectively.

By optimizing the water-to-cement ratio, we’ve found that not only is the strength and durability of the concrete structure heightened, but we also see significant reductions in maintenance costs and materials wasted.

From our experience, the strategic application of this law can extend the lifespan of structures and further curb replacement costs. Therefore, it is essential for builders, contractors, and construction project managers to not only understand Abrams’ Law but also apply it practically in their work. In essence, Abrams’ Law can unlock cost savings and quality improvement in construction, adding another level of robustness to our buildings.