Introduction To Transducers

Have you ever wondered what happens behind the scenes in construction?

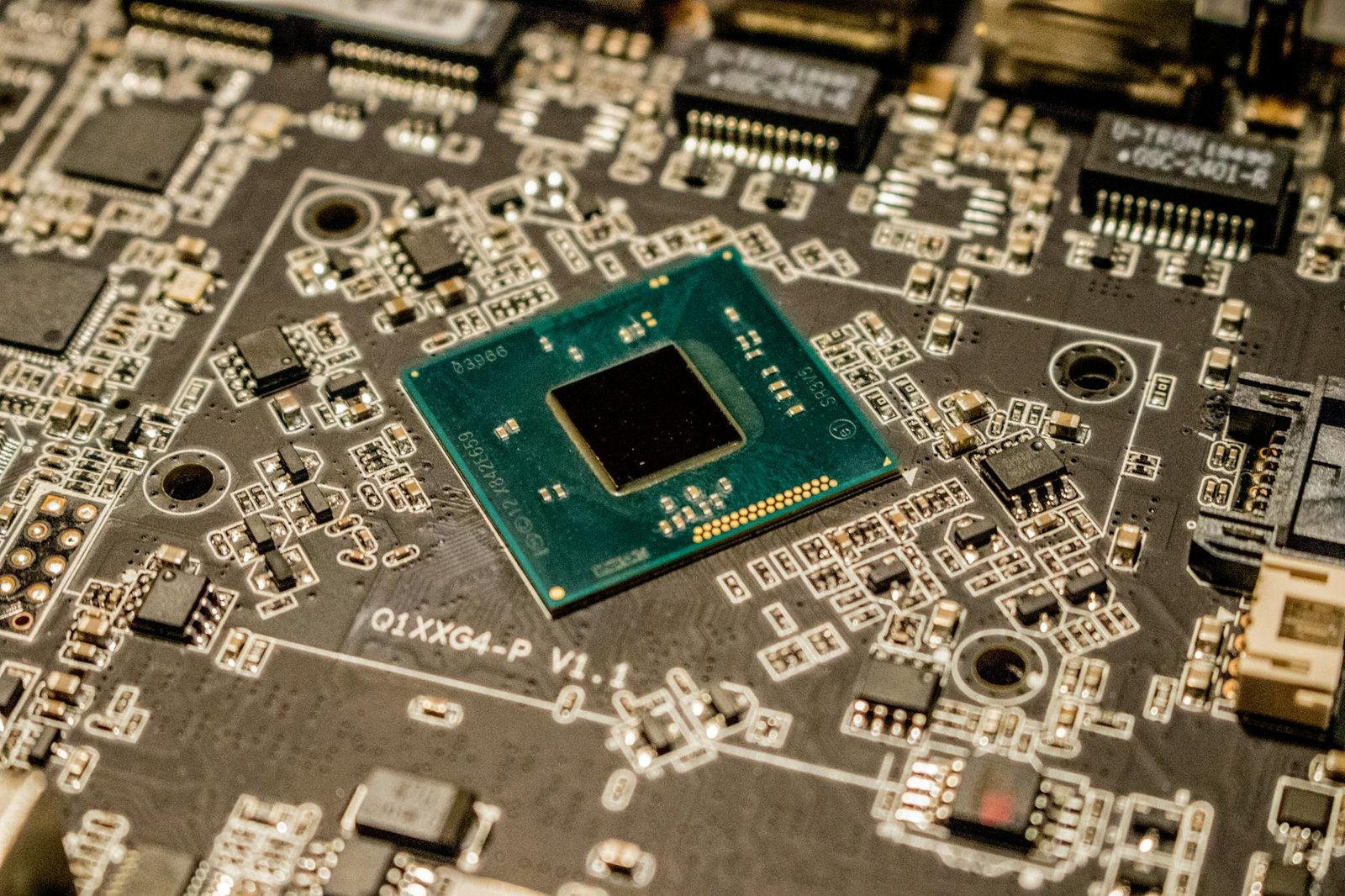

One crucial component you may not be aware of is a device called a transducer. This simple yet essential gadget is largely responsible for converting one form of energy into another, such as physical changes into electrical signals, making it extremely vital in numerous industries, particularly in construction.

In this article, we will explore what a transducer is, its different types, and how it works. Additionally, we will delve into their application in construction projects, what to look for when choosing a transducer, and the essential role they play in ensuring a project’s success.

Stay with us if you’re interested in how such a small piece of technology can have a significant impact on large-scale construction projects.

Table of Contents

Transducer: A Key Concept in Construction

Defining a Transducer

A transducer is a crucial device used in various industries, including construction. It is typically seen in electronic systems. In basic terms, a transducer is a device that changes one form of energy into another. More commonly, this term describes a device converting electrical energy into a physical change.

Types of Transducers

Though a transducer generally shifts forms of energy, specificity matters. Transducers can perform different functions based on the industry and usage. In construction, types of transducers might include:

- Pressure Transducers

- Temperature Transducers

- Ultrasonic Transducers

The Working Mechanism

The key aspect of a transducer is its conversion process. It senses a form of energy and modifies it into converted energy. For instance, the process can be converting a physical phenomenon into an electrical signal. With efficient processing, transducers maintain high reliability and accuracy.

Application in Construction

In the construction context, transducers have a wide range of uses. They are often applied in sensing conditions, controlling systems, and measuring parameters. For instance, a pressure transducer could be used to monitor the overall structural health in a construction project, alerting the project manager of any abnormal pressure changes.

Features of a Good Transducer

While choosing a transducer, several aspects should be considered:

- Mechanical robustness and resistance to rough environmental conditions

- Precision and repeatability of readings

- Ease of use and installation

Basic Comparison of Transducer Types

| Type of Transducer | Main Use |

|---|---|

| Pressure Transducer | Sensing and measuring pressure changes in structures |

| Temperature Transducer | Reading temperature variations and alerting of any deviations |

| Ultrasonic Transducer | Sending and receiving ultrasonic waves, mainly applied in distance approximation |

For more information on transducers in construction, check out this comprehensive article on Electronics Notes. Remember, the right transducer selection can balance functionality and efficiency, ensuring the safe and successful execution of construction projects.

Requirements for an Effective Transducer

Energy Conversion Efficiency

One significant characteristic of a transducer is its energy conversion efficiency. This requirement is crucial because the more effective a transducer is at converting one form of energy into another, the better it can perform its functions. Some transducers, like ultrasonic types, must convert electrical energy into sound waves and vice versa without significant energy loss.

Operating Conditions

A transducer’s capacity to function under specific conditions is also essential. For instance, in a construction site, transducers may be exposed to extreme temperatures, vibrations, pressure, and even corrosive circumstances. Therefore, a construction transducer must be robust enough to work efficiently under these conditions.

Sensitivity

Sensitivity is another vital attribute of a transducer. The transducer’s sensitivity should be high to detect minor changes in input signals. This sensitivity allows the user to monitor subtle variations and respond accordingly.

Effect of Sensitivity on Transducers

| Type of Transducer | Impact of Sensitivity |

|---|---|

| Pressure Transducer | Detects minor pressure variations, increasing safety and enabling quick responses |

| Temperature Transducer | Identifies minute temperature changes, ensuring optimal working conditions |

| Ultrasonic Transducer | Picks up slight changes in sound wave transmission, enhancing accuracy in distance approximation |

Stability and Repeatability

Transducers must provide stable and repeatable readings over time. Stability means that the transducer will still give consistent readings even carrying similar measurements overtime. On the other hand, repeatability refers to a transducer’s ability to give identical results when exposed to the same conditions multiple times. Stability and repeatability ensure the reliability and accuracy of data provided by the transducer.

Measurement Range

Measurement range refers to the minimum and maximum limits within which a transducer can accurately measure a parameter. A broad measurement range implies that the transducer can handle a wide array of conditions without compromising its performance. A pressure transducer used in construction should handle both low and high-pressure levels for its versatility.

For further reading about the specifications of transducers, this Electronicshub article offers a deep dive into the topic. By understanding these requirements of a transducer, you may optimize your selection for improved project efficiency and safety.

The Concept of Sensor Stability

Defining Sensor Stability

Sensor stability is an important aspect when discussing the effectiveness and reliability of a transducer. This particular characteristic deals with a sensor’s ability to maintain its performance standards over a prolonged period or under varying conditions. It refers to the measure of a sensor or transducer’s output consistency over time in response to the same input or environmental conditions.

Importance of Sensor Stability

The stability of a sensor is crucial in various industries, including construction, where consistent, reliable data is necessary for efficient operations and risk management. If a sensor does not maintain its stability:

- The accuracy of results it gives could deteriorate over time.

- It might provide inconsistent readings under similar conditions.

- It could lead to safety and operational issues in a construction project, as unreliable data can lead to misinterpretation of structural integrity.

Factors Influencing Sensor Stability

Several factors can affect a sensor’s stability, including:

- Environmental Conditions: Exposure to extreme temperatures, vibrations, pressure, and humidity can degrade the sensor’s performance over time.

- Material Degradation: The transducer’s materials can degrade due to age, wear and tear, or corrosion, leading to instability.

- Calibration: Incorrect or infrequent calibration can lead to instability in sensor readings.

- Power Supply: Inconsistent or unreliable power can affect the stability of a sensor.

Maintaining Sensor Stability

To ensure sensor stability, the following aspects should be considered:

- Regular Calibration: Regular calibration can help detect any deviation in sensor performance and calibrate it to provide accurate and reliable results.

- Protected Installation: Installing sensors in protected environments where they are shielded from extreme conditions can improve stability.

- Use of Robust Materials: Choosing sensors made of robust, long-lasting materials can ensure they withstand the test of time and use.

- Proper Power Management: Ensuring a constant, reliable power source is crucial for stable sensor operation.

It’s A Fact: Transducer Stability Matters

| Type of Transducer | Why Stability Matters |

|---|---|

| Pressure Transducer | Stable readings ensure structural safety, as pressure changes can indicate potential risks. |

| Temperature Transducer | Stability is key to maintaining the structural integrity of a project, as fluctuating temperatures can affect materials. |

| Ultrasonic Transducer | Stable readings ensure accurate distance approximation over prolonged periods or repeated measurements. |

For more detailed information on the importance of sensor stability and how to achieve it, be sure to check out the article “The Importance of Sensor Stability in Controlled Environments” from Sensors Magazine. By prioritizing transducer stability, you can help ensure the longevity, success and safety of your construction projects.

Understanding Stability in Pressure Transmitters

Defining Stability in Pressure Transmitters

Stability in pressure transmitters can be seen as the ability of the pressure transmitter to hold its performance characteristics constant over a period. More directly, a pressure transmitter’s stability relates to the consistency of its readings when exposed to the same pressure repeatedly over time.

Why is Stability in Pressure Transmitters Important?

Stability in a pressure transmitter is crucial for an assortment of reasons:

- Consistent Data: Stability allows the transmitter to produce predictable and consistent pressure data, which enhances the efficiency and control of the process.

- Safety: In many industries, sudden pressure changes can pose significant risks. A stable pressure transmitter can reliably track these changes, ensuring the safety of workers and machinery.

- Economic Efficiency: A stable pressure transmitter requires less recalibration, reducing maintenance time and cost.

Factors Affecting Stability in Pressure Transmitters

Several factors can influence the stability of pressure transmitters:

- Quality of Components: The quality and durability of components used in constructing the pressure transmitter can significantly affect its stability.

- Environmental Conditions: Too much exposure to temperature changes, moisture, or extreme pressure conditions can impact the transmitter’s performance and stability.

- Vibration: Heavy machinery operation can cause vibrations that disturb pressure transmitter performance.

Improving Stability in Pressure Transmitters

Here are some steps you can take to ensure optimum stability in a pressure transmitter:

- Quality Products: Invest in pressure transmitters from reputable manufacturers to ensure quality and durability.

- Proper Installation: Install the pressure transmitter correctly and in a controlled environment as much as possible.

- Regular Calibration: Regularly recalibrate the pressure transmitter to maintain its performance and accuracy.

Key Takeaways from Pressure Transmitter Stability

| Pressure Transmitter | Key Considerations for Stability |

|---|---|

| Consistent Data | Invest in quality products for dependable readings |

| Safety | Ensure proper installation to minimize risks from pressure changes |

| Economic Efficiency | Regular calibration reduces the need for frequent replacements |

Want to learn more about the importance of stability in pressure transmitters? Check out this article from Omega. It offers a comprehensive guide on the subject, including detailed explanations of why stability matters and tips on how to maintain it. Follow these steps, and you can achieve reliable and consistent results from your pressure transmitters.

In Conclusion…

Transducers serve as vital devices within multiple sectors, notably in the construction industry, thanks to their impressive energy conversion efficiency and versatility. This versatility is proven through the different types of transducers, like pressure, temperature, and ultrasonic transducers, each with unique functions pertinent to construction.

The elements making up an effective transducer include energy conversion efficiency, adaptability to different conditions, sensitivity, stability, and repeatability as well as a wide measurement range. Specifically, sensor stability contributes significantly to a transducer’s reliability, ensuring consistent detection of subtle changes in various environments.

Furthermore, understanding stability in pressure transmitters is essential in securing consistent data and maintaining safety and economic efficiency within a construction project. Therefore, vigilance in maintaining the stability of transducers and understanding their distinct characteristics is critical in achieving favorable outcomes in construction endeavors.

Frequently Asked Questions – FAQs

What are the different types of transducers in construction?

There are several types, including but not limited to pressure, temperature, and ultrasonic transducers.

What makes an effective transducer?

Key factors include energy conversion efficiency, performance under varying conditions, sensitivity, stability, repeatability, and a wide measurement range.

What is sensor stability?

Sensor stability refers to the ability of a sensor to maintain its performance over extended periods, under varying conditions.

Why is pressure transmitter stability important in construction?

It ensures consistent data, safety, and reduces maintenance costs because stable transmitters require less recalibration.