Breaking Down the Construction Lingo

Internal Curing (IC) serves as an alternative approach to traditional concrete curing.

The objective is to enhance the strength, durability, and performance of the infrastructure the concrete supports.

Coping with material selection, understanding IC’s hidden potential, and overcoming practical implementation hurdles can pose quite the challenge.

Let’s break this down further.

Table of Contents

Internal Curing: Understanding the Challenges

Internal Curing (IC) is a construction technique that significantly alleviates the challenges of concrete shrinkage and durability.

However, as promising as IC is, it’s not without its challenges.

From material selection to understanding IC’s full potential, there are both practical and theoretical issues to overcome.

Complications of Material Selection

Appropriate Aggregate Selection

Internal curing relies heavily on the use of pre-wetted lightweight aggregates, which are known for their superior ability to retain and release water. However, sourcing these specific aggregates can be challenging due to:

- Limited supply: Not all regions have ready access to lightweight aggregates.

- Cost: These aggregates tend to be more expensive than traditional materials.

- Quality control: Ensuring the aggregates consistently maintain the necessary wetness can be a logistical difficulty.

Understanding IC’s Full Potential

The Theoretical versus Practical Application of IC

While the theory of internal curing is well-established and proven in lab settings, transferring those results to real-world applications can be problematic. Challenges associated with this include:

- Environmental conditions: Actual project sites won’t behave like controlled lab environments, potentially reducing IC’s effectiveness.

- Implementation: Training personnel effectively in new techniques can be time-consuming and costly.

Estimating Water-Cement Ratio

The Precision Required in Water Measurement

Water-cement ratio plays a critical role in internal curing. Overestimation could lead to excess water, affecting the strength of the mix, while underestimation affects hydration. Challenges include:

- Measurement: Precisely measuring water volumes on busy job sites is tough.

- Fluctuation: Water levels in lightweight aggregates can fluctuate due to atmospheric conditions, making it tricky to achieve ideal ratios.

Although implementing internal curing in construction has its share of challenges, this revolutionary method offers too many potential benefits to be disregarded.

With better understanding, improved materials, and more accurate water-cement ratios, these challenges can gradually be mitigated.

References:

The information covered in this blog has been obtained from reliable sources such as American Concrete Institute and National Ready Mix Concrete Association.

Exploring the Costs and Benefits

Costs of Internal Curing

Being informed about the potential costs that internal curing entails is vital in order to determine if the method is suitable for your concrete project.

Initial Investment

The internal curing method necessitates the use of special curing materials such as pre-wetted Lightweight Fine Aggregates (LWFA). The cost of these materials can be higher than traditional curing resources.

Implementation Training

Additional expenses can be incurred in training personnel on efficient techniques and the best practices of internal curing.

Long-term Maintenance Costs

Even though internal curing typically results in a more durable solution, it may potentially require long-term maintenance which can add to the overall project expenses.

Benefits of Internal Curing

Despite the costs, internal curing has numerous benefits that make it a promising solution in numerous construction scenarios.

Enhanced Durability

Internal curing can optimize the hydration process of the cement, leading to lower permeability and subsequent enhancements in durability and longevity.

Reduced Shrinkage and Cracking

One of the most notable benefits of internal curing is its ability to significantly reduce concrete shrinkage and cracking, thereby improving the concrete’s aesthetic and structural integrity.

Improved Strength

By promoting a more complete hydration process, internal curing often results in concrete with greater strength, adding to the robustness of the construction project.

Summing Up

Like any construction practice, internal curing comes with its own set of costs and benefits.

The value and viability of the process are largely dependent on the requirements and budget of your specific project.

For a more comprehensive evaluation, this publication from the Iowa State University Center for Transportation Research and Education provides an in-depth study on the cost-effectiveness of internal curing in concrete pavements.

Comparative Analysis With Traditional Curing Methods

Common Traditional Curing Methods

- Water Curing: This involves regularly sprinkling the surface of the concrete with water or immersing it in water to maintain moisture content.

- Steam Curing: In this method, the concrete is exposed to steam at a controlled temperature and for a specific duration.

- Membrane Curing: A plastic sheet or curing compound is used to prevent water evaporation from the concrete surface.

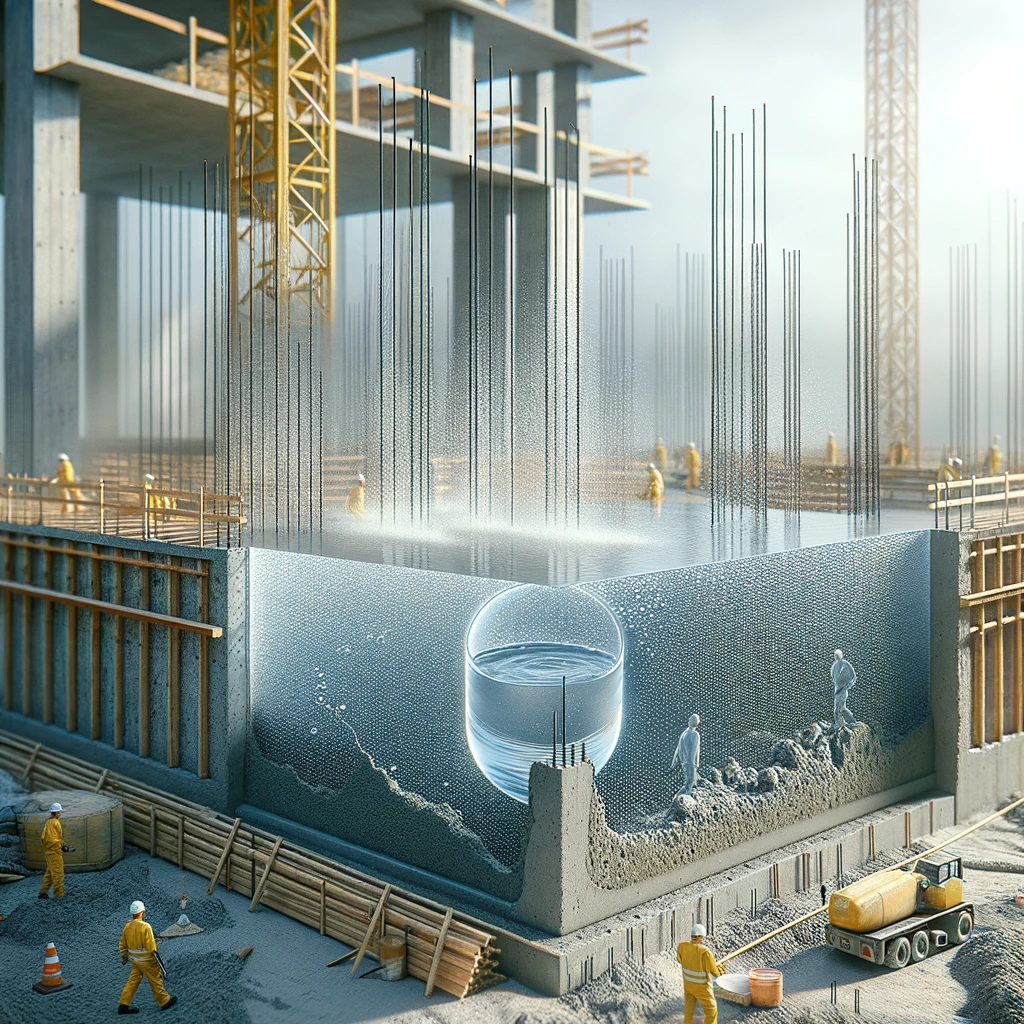

In contrast, internal curing is a concrete hydration process that uses porous, absorbent lightweight aggregates that have been pre-wetted. When mixed with the cement, these aggregates release their stored water, providing additional curing from the inside.

This can result in improved strength, less shrinkage, and increased toughness.

Advantages Of Internal Curing

- Minimizes early-age cracking: Internal curing supplies additional moisture that can reduce early-age shrinkage cracking, thereby enhancing the durability and longevity of the concrete.

- Improved hydration: Unlike traditional curing methods that can only hydrate the surface of the concrete, internal curing allows for a complete hydration process throughout the entire volume of the concrete.

- Efficient water usage: Internal curing uses water more efficiently, which is particularly beneficial in areas experiencing water scarcity.

Summary Table

| Curing Methods | Definition | Unique Advantage |

|---|---|---|

| Traditional Curing | External moisture provision to help concrete harden | Versatility in techniques |

| Internal Curing | Hydration process that uses pre-wetted aggregates to help concrete harden | Enhanced hydration, reduced cracking |

Conclusion On Internal Curing

There’s more to curing than just pouring water over concrete!

From the versatile methods of traditional curing to the in-depth hydration provided by internal curing, each approach offers a unique set of benefits.

When chosen properly based on the specific needs and constraints of a project, these curing methods can greatly enhance the durability, strength, and performance of concrete constructions.

From our perspective, it’s evident that Internal Curing (IC) stands as a significant advancement in construction despite the challenges it presents.

While grappling with the intricacies of appropriate aggregate selection and estimating water-cement ratios can be demanding, there’s no denying the potential of this technique to combat concrete shrinkage and enhance durability.

What’s clear is that the journey does not end here.

We need to continually refine techniques, perfect material selection, and ultimately, realize the full potential of Internal Curing. Through careful nurturing of these aspects, there is enormous potential for IC to establish itsel as an integral part of the construction process.

To learn more about these curing methods, check out the National Ready Mixed Concrete Association’s guide to internal curing.