The Essential Guide to Backfilling: A Deep Dive

Have you ever stumbled across the term ‘backfilling’ and wondered about its significance in construction?

That’s precisely what I’m here to clarify.

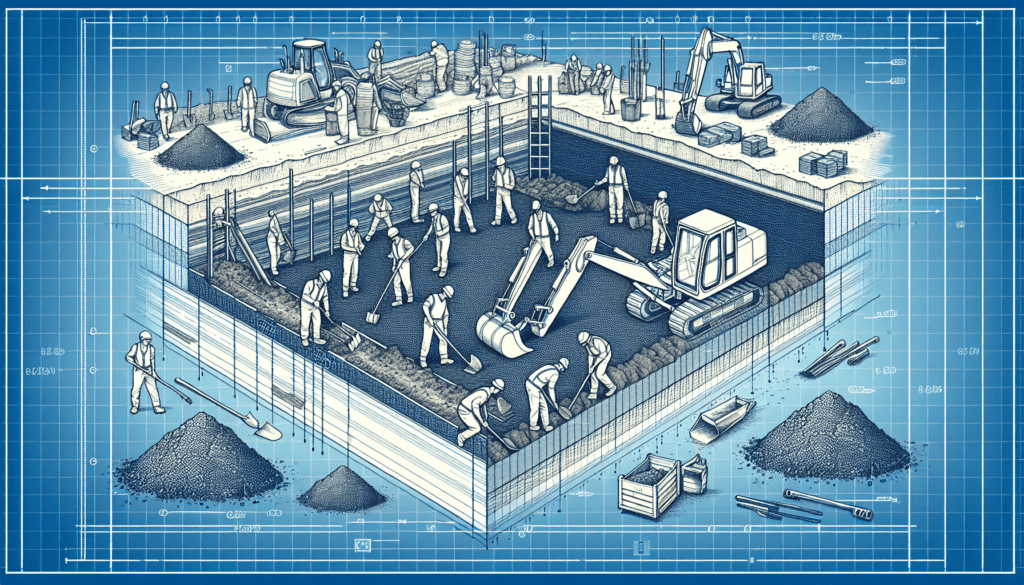

‘Backfilling’, in construction terms, is the act of replacing soil or earth after excavation. It might sound simple, but there’s a fascinating science behind it.

Intrigued yet?

Let’s dig deeper.

Table of Contents

Understanding Backfilling in Construction: A Comprehensive Guide

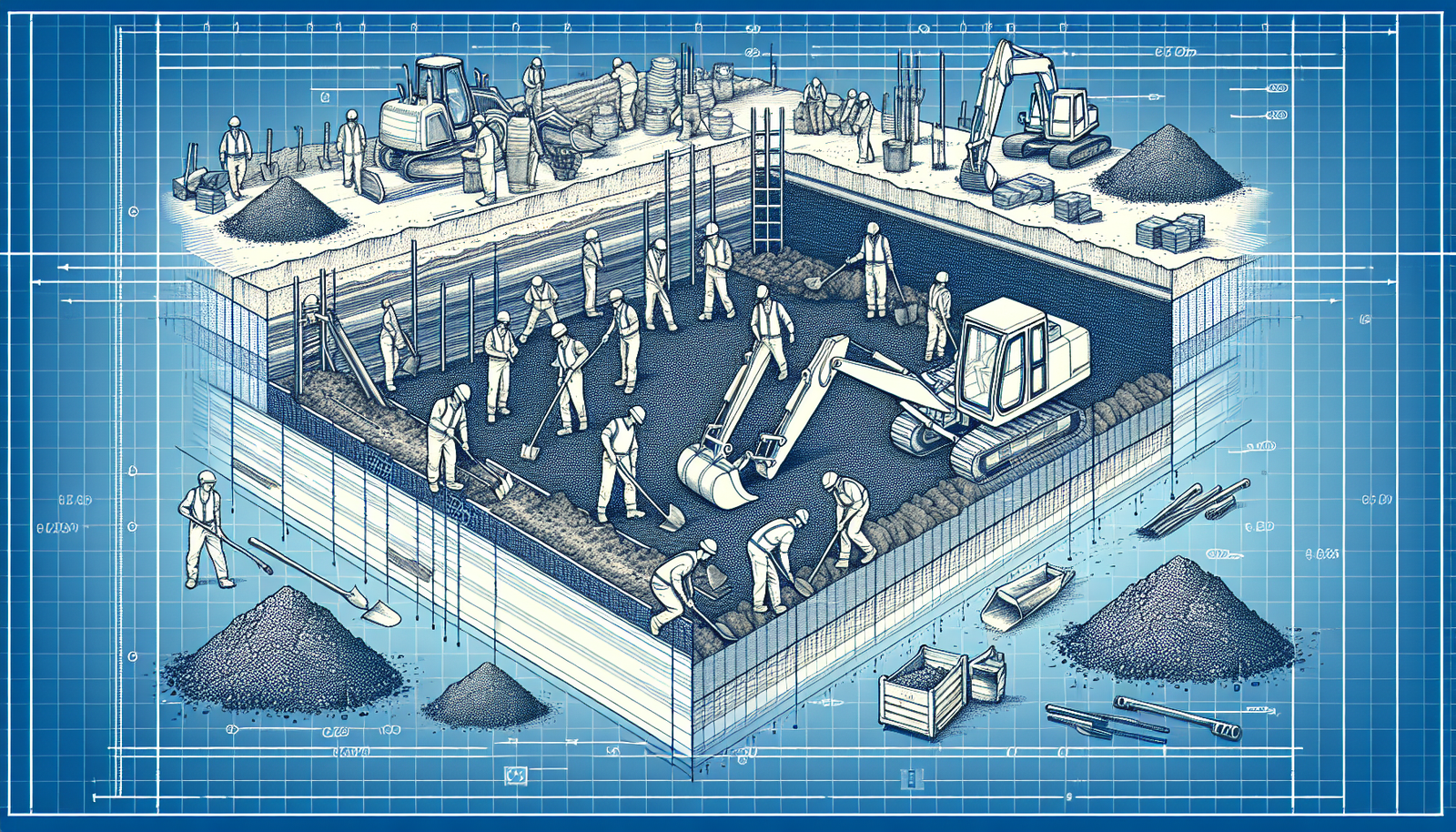

Construction can be a jargon-filled industry brimming with technical terms that might seem gibberish to the uninitiated. One such crucial term to understand is ‘backfilling’. To both novices and professionals alike, one question often arises: “Can backfilling be done manually, or does it require professional equipment?”

What is Backfilling?

In simplistic terms, backfilling is the process of replacing or reusing the soil that was removed during construction. This is typically done after the structural work has been completed to provide stability and prevent any possible subsidence.

Can Backfilling Be Done Manually?

The short answer is yes, backfilling can be carried out manually. However, the suitability of this approach largely depends on the scale of your project.

Pros of Manual Backfilling

- It’s economical since you don’t need to hire or buy expensive machinery.

- Ideal for small scale projects or hard-to-reach areas.

Cons of Manual Backfilling

- It’s labor-intensive and can significantly extend the project timeline.

- Potential for inconsistent compaction if not performed carefully.

Does Backfilling Require Professional Equipment?

While manual backfilling is feasible, professional equipment is often the go-to choice for larger projects.

Pros of Using Professional Equipment for Backfilling

- Massive time savings as machinery can work more rapidly than manual labor.

- Ensures consistent compaction, essential for preventing future ground settlement.

Cons of Using Professional Equipment for Backfilling

- Higher upfront costs for equipment rental or purchase.

- Not always practical in confined spaces or delicate sites.

Calculating the Cost of Backfilling in Construction

Factors Affecting the Cost of Backfilling

The cost of backfilling in construction is dependent on a variety of factors. Here are the most crucial ones:

- Type of soil: Some soils are more expensive than others. The price will be influenced by the soil’s quality, whether it’s topsoil, subsoil, or a mix.

- Quantity: The more soil you need to backfill, the higher the expense.

- Access and location: Costs can increase if access is restricted or if the location is remote, requiring greater transportation efforts.

- Labor: Skilled workers are essential for this process, so costs can escalate with additional labor needs.

How to Calculate the Cost of Backfilling

The exact cost of backfilling can be calculated using a simple equation:

| Cost Calculation |

|---|

| (Cost of Soil per Yard + Transportation Costs + Labor Costs) x quantity of soil needed |

Cost of Soil

You can find the cost of soil from resources like local garden centers, nurseries, or construction material suppliers. These costs will generally be provided per cubic yard.

Transportation costs

The cost of transporting the soil to the site will depend on your location and the distance from the soil supplier.

Labor Costs

Labor costs can be tricky to calculate, as it depends on the complexity of the job, the number of laborers, and the average wage rates in your area. You can get an accurate estimate by consulting with a local construction company.

In conclusion, calculating the cost of backfilling is more straightforward than it initially appears. It’s just a matter of understanding the different contributing factors and using the appropriate equation. Always get estimates from multiple sources to ensure you’re getting a fair price.

Effective Tips to Save Money During the Backfilling Process

Understanding Backfill Material

Use Local, Recycled Materials

Using local or recycled materials can significantly reduce the costs associated with the backfill process. These materials often come at a lower cost, and it reduces the environmental impact of construction.

- Soil: Utilizing the soil excavated from the same site or local excavations can provide cost savings. Ensure the soil is suitable for backfill and doesn’t have contaminants.

- Recycled concrete: Crunched up concrete from local buildings demolition can serve as a cheap alternative backfill material.

Bid and Contract Strategies

Competitive Bidding

Encourage competitive bidding, involving multiple contractors. It helps ensure the backfill work is awarded to the one offering quality and cost-effective service.

Contract Agreements

Formulate contract agreements precisely to have provisions for unexpected changes and potential extra costs during the backfilling process.

Efficient Planning & Execution

Effective Scheduling

A well-integrated work schedule can save money on the project. Instead of having idle machinery sitting, ensure the backfilling process is scheduled immediately after excavation, saving costs on equipment usage and rental.

Quality Control

Quality checks can prevent costly repairs or any needed redoing of the backfilling process. Tests such as Compaction and Proctor tests ensure the backfill is structurally sound.

| Tip | Potential Savings |

|---|---|

| Use local, recycled materials | Cost of buying and transporting foreign materials |

| Competitive Bidding | May achieve lowest price for quality work |

| Effective Scheduling | Reduces idle time and equipment rental costs |

| Quality Control | Preventive costs of redoing or repairing backfill work |

Backfilling is a vital part of construction that holds potential for cost savings when done right. With cost-effective strategies such as utilizing local materials, encouraging competitive bidding, planning effectively, scheduling wisely, and ensuring quality control, considerable money can be saved during the backfilling process.

Conclusion: Digging Deeper into Backfilling

From our exploration, we’ve discovered that backfilling is much more than merely refilling an excavation pit. It is an intricate part of the construction process that requires careful selection of materials and proper compaction to ensure the stability and longevity of structures.

In our experience, backfilling plays a critical role in reinforcing structures, deterring soil erosion, and even sculpting landscapes. Not just any soil can meet these requirements. The right backfill material needs to possess the right balance of compaction, low permeability, and durability.

Understanding these complexities rescues backfilling from the realm of the overlooked and highlights its true importance to the construction world. The next time you see a construction in progress, reflect on the unseen art of backfilling, a process that sets the stage for the marvels of architecture that shape our world.