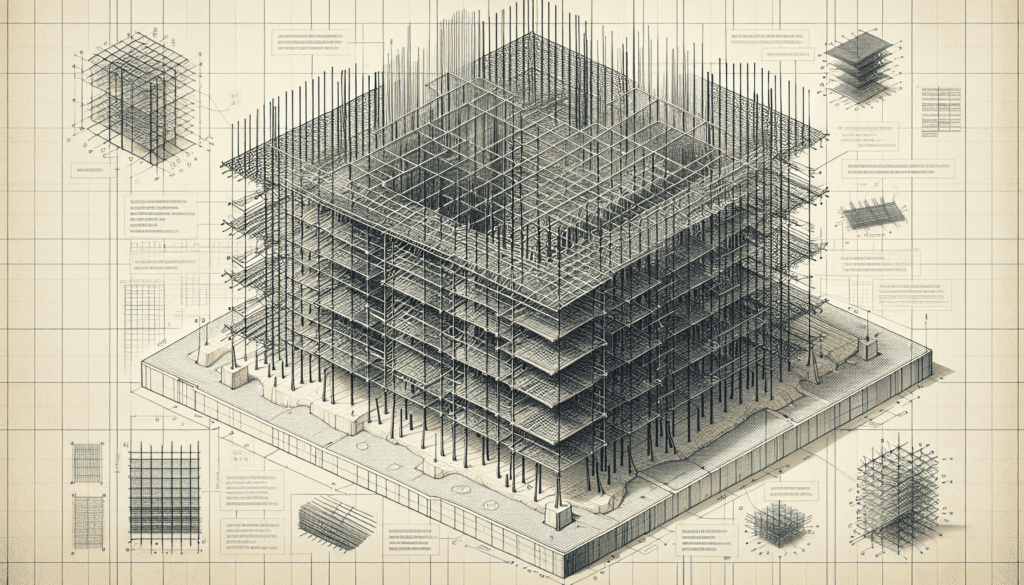

Mesh Reinforcement in Construction

A term we hear often in construction lingo is mesh reinforcement.

But, what does it mean?

Mesh reinforcement involves interlacing strips or bars of material, forming a grid and utilizing this within construction materials, for strength and durability.

The purpose?

Ensuring that the structures you see standing tall continue doing so, year after year.

Read on to learn more about this indispensable construction technique and how it contributes to building our world.

Table of Contents

Understanding Mesh Reinforcement in Construction

How Mesh Reinforcement Enhances Durability

There are key ways in which mesh reinforcement significantly contributes to the durability of structures:

- Increased Tensile Strength: Concrete is known for its high compressive strength, but its tensile strength is relatively weak. By adding a metal grid or mesh, the tensile strength is significantly increased, helping prevent cracking under tension.

- Improved Crack Control: All concrete has a tendency to shrink and crack over time. Mesh reinforcement helps distribute the tension across the structure, thereby reducing the occurrence and extent of cracking.

- Enhanced Load-Bearing Ability: Mesh reinforcement enables structures to withstand higher loads. This is especially critical in structures like bridges and high-rise buildings that need to support significant weight.

- Increased longevity: By effectively mitigating cracking and enhancing the structure’s load-bearing capacity, mesh reinforcement prolongs a construction structure’s life span.

Applications of Mesh Reinforcement in Construction

Mesh reinforcement is applicable in a variety of construction structures, including but not limited to:

- Floors and walls in buildings

- Fencing posts

- Floor slabs

- Concrete roads

- Road and railway improvement projects

By utilizing mesh reinforcement, construction professionals can build stronger, more durable structures that can withstand the tests of time and adverse conditions.

For a more in-depth exploration of construction materials and their application, please read this fantastic article on Evaluating and Selecting Construction Materials.

Different Types of Mesh Reinforcement Materials

There are several different types of mesh reinforcements made from various materials, each with their unique characteristics and suitability for different projects.

Types of Mesh Reinforcement Materials

The selection of the right mesh reinforcement material depends on the construction project’s specific needs. Here are some of the most commonly used materials:

1. Steel Mesh

Steel mesh is one of the most common types of reinforcement mesh material used in the construction industry. It is highly durable, strong, and offers excellent resistance against corrosion.

2. Synthetic Fiber Mesh

This type of mesh reinforcement is made from materials such as polypropylene, polyester, and nylon. Synthetic fiber mesh isn’t as durable as steel, but it’s lightweight, making it easier to handle and install.

3. Glass Fiber Mesh

A high-quality yet affordable reinforcement material, glass fiber mesh provides great strength and stability. Its resistance against chemical attack and its minimal condensation make it popular in making water-tight structures.

4. Wire Mesh

Wire mesh is a cost-effective solution for small projects or those requiring lower tensile strength.

Comparison of Mesh Reinforcement Materials

| Type | Durability | Cost | Best Used For |

|---|---|---|---|

| Steel Mesh | High | High | Large-scale projects needing high tensile strength |

| Synthetic Fiber Mesh | Medium | Medium | Projects requiring lightweight materials |

| Glass Fiber Mesh | Medium | Low | Water-tight structures |

| Wire Mesh | Low | Low | Small-scale projects or low tensile strength applications |

In conclusion, the type of mesh reinforcement material to be used largely depends on the project requirements, including the need for tensile strength, resistance to corrosion and ease of installation.

Cost-Effective Mesh Reinforcement Solutions for Small Scale Construction

In the context of small-scale construction projects, affordable and practical solutions are essential to maximizing efficiency without compromising quality.

Here are some cost-effective mesh reinforcement solutions that you can utilize in your construction project.

Wire Mesh

Wire mesh is a popular and affordable reinforcement solution, especially utilized in concrete construction. Constructed from steel wires that are welded together at each cross section, this option provides the ultimate combination of affordability, availability, and strength.

Fiber Mesh

Fiber mesh is a cost-effective reinforcement solution often used as an alternative to traditional wire mesh. It consists of fibrous materials mixed into the concrete to increase its tensile strength and reduce the possibility of cracks.

Types of Fiber Mesh

- Synthetic Fibers: Made from materials like polypropylene or polyester, these are resistant to elements and ideal for outdoor constructions.

- Steel Fibers: Although slightly more expensive than synthetic fibers, these provide enhanced reinforcement and have high strength-to-weight ratio.

- Glass Fibers: These are primarily used to reinforce cement and concrete products in non-structural applications.

Plastic Mesh

A more modern, yet still cost-effective, solution is plastic mesh reinforcement. Plastic mesh can be treated to withstand chemical reactions and is incredibly resistant to rust, providing durable support to structures.

Benefits and Limitations

| Type | Benefits | Limitations |

|---|---|---|

| Wire Mesh | Affordable, Widely Available, Adds Strength | Can Rust Over Time, Requires Additional Labor To Install |

| Fiber Mesh | Resistant To Shrinkage Cracks, Increases Tensile Strength | Not Ideal For Heavy Traffic Areas, Can Alter Concrete Color If Not Mixed Properly |

| Plastic Mesh | Resistant To Rust, Lightweight | Less Tensile Strength Than Steel, More Expensive Than Wire And Fiber Mesh |

A Conclusion on Cost

While each type of mesh reinforcement has its pros and cons, they all provide cost-effective solutions for small-scale construction projects. It’s important to choose a solution that aligns with the specific needs and budget of your project.

Remember that the “cheapest” solution isn’t always the most cost-effective in the long term.

By considering the potential maintenance, duration, and sustainability costs, you can make a wise investment for your project.

Now It’s Your Turn To Not Mesh Anything Up

In our analysis, we’ve found that every mesh reinforcement solution, from Wire Mesh to Fiber and Plastic Mesh offers valuable benefits for small-scale construction projects, each with diverse attributes.

From our perspective, Wire Mesh offers affordability and strength, while Fiber Mesh proves itself with enhanced resistance to shrinkage cracks and Plastic Mesh shines in its rust-resistant properties.

While each has its limitations, these materials provide diverse virtues that cater to various construction requirements and budgets.

However, it’s essential to carefully consider not only the present cost, but also the long-term implications and potential maintenance expenses.

Our experience suggests that the most cost-effective choice may not always be the least expensive upfront—sometimes, investing a bit more can lead to larger savings down the line. Individual project needs and objectives will always govern the ultimate choice of reinforcement material.