Introduction To Flush Joints

In this article, we’re going to explore the world of construction, where aesthetics meet practicality through methods like joint flush.

Imagine having two flat surfaces meet without any visible signs of joining – that’s what a flush joint achieves.

Whether you’re a construction professional or simply curious about how buildings come together, you’ll find this guide informative. We’ll explain what joint flushing is, what materials are used, how it’s applied, and some common challenges faced during installation. We’ll also examine the variety of masonry joints, their advantages, and where each type is commonly used.

And did you know that not all mortar joints are created equal? Yes, some are weaker than others! Don’t worry, we’ll discuss those as well, along with some ways to improve their strength.

Let’s get started!

Table of Contents

Understanding Flush Joint in Construction

Definition of Flush Joint

A flush joint refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting in a smooth, even surface. This technique ensures that the seams are barely noticeable and the structure appears continuous.

Materials Used in Flush Joint

The materials used to achieve a flush joint can vary depending on the surfaces being joined and the desired final appearance. Common materials include:

- Mortar: A mix of cement, lime, sand, and water used in masonry work.

- Sealant: A flexible material used to close gaps and provide a smooth finish.

- Plaster: A paste used on walls and ceilings to create a smooth surface.

Applications of Flush Joints

Flush joints are implemented in various construction projects to achieve both functional and aesthetic goals. Key applications include:

- Building Facades: To ensure an even surface for exterior walls.

- Interior Walls: For seamless and visually appealing wall finishes.

- Tile Installation: To create a smooth, continuous tile surface without visible gaps.

Technique and Installation

Step-by-Step Process

Here’s a general procedure for creating a flush joint:

- Surface Preparation: Ensure both surfaces to be joined are clean and dry.

- Applying Material: Use a trowel or applicator to fill the joint with the chosen material.

- Smoothing: Level the material with a tool, making sure it is flush with the surfaces.

- Drying/Curing: Allow the material to set or cure as per the manufacturer’s instructions.

- Sanding (if necessary): Sand the surface to achieve a perfectly smooth finish.

Best Practices

To achieve the best results when creating a flush joint, consider the following tips:

- Choose the right material for the job, taking into account the surfaces and environmental conditions.

- Ensure thorough mixing and consistent application to avoid weak spots.

- Apply the material in small, manageable sections to maintain control.

- Regularly check your work with a level or straight edge as you go.

Common Challenges

When working with flush joints, you might encounter some challenges:

- Shrinkage: Improperly mixed materials can shrink and create gaps as they dry.

- Cracking: If the material is not flexible enough, thermal expansion or settling can cause cracks.

- Uneven Finish: Lack of attention during application can result in a non-uniform surface.

Solutions

To counter these challenges, consider these solutions:

- Use high-quality, flexible materials suitable for the specific application.

- Ensure proper curing time and environmental conditions during the drying phase.

- Maintain consistent technique and double-check the finish regularly.

The Variety of Masonry Joints

Introduction to Masonry Joints

In masonry construction, joints are utilized where individual masonry units, such as blocks, bricks, or stones, connect. Akin to the joint flush technique, different types of masonry joints are effectively used to not only aid the structural integrity of a building but also to enhance its aesthetic appearance.

Types of Masonry Joints

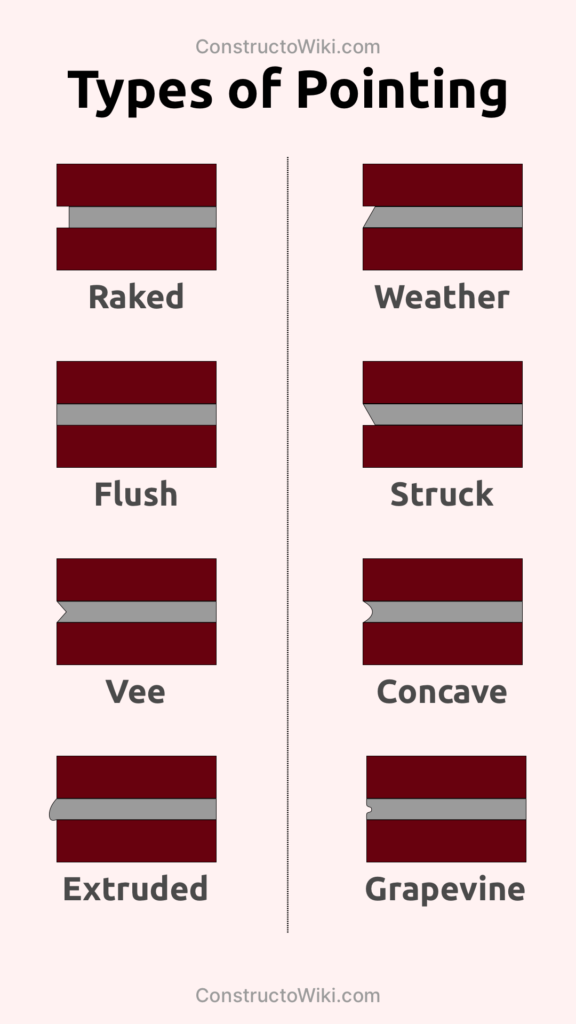

Below are common types of masonry joints, each implying distinct techniques and applications:

- Flush Joint: As previously explained, it provides a smooth finish by filling and leveling the joints with materials like mortar.

- V Joint: Here, the mortar protrudes out in a V-shape, typically used in brick walls for decorative effects.

- Weathered joint: In this method, the upper edge of the joint is pressed down while the lower edge is kept out. The design provides better runoff for rainwater, making it useful in areas with high rainfall.

- Concave joint: Mortar pressed in a curved form serves to compact the joint and aid water runoff, making it popular due to its resistance to harsh weather conditions.

- Raked joint: Mortar is recessed in a uniform depth, presenting a significant shadow effect ideal for decorative walls.

Selection of Masonry Joints

Choosing the right masonry joint depends on several factors, including:

- Environmental conditions: In areas of heavy rainfall, weathered or concave joints may be employed.

- Aesthetic appeal: For a more dramatic or decorative effect, V or raked joints may be chosen.

- Structural needs: Flush joints are commonly used for their smoothness and improved interface between masonry units.

Construction and Challenges

Process of Masonry Joint Application

The process of constructing masonry joints is specific to each type, but commonly involves:

- Laying the stones/bricks: Prepare and place the masonry units for the creation of joints.

- Applying Mortar: Apply mortar in the joints by using a pointing trowel.

- Shaping the Joint: Different types of pointing tools are utilized to give the joint its required shape.

- Curing: Allow the joint to cure under suitable conditions.

Challenges

Similar to joint flush construction, some challenges could occur such as:

- Mortar Shrinkage: An incorrect mix can lead to mortar shrinkage, hence affecting the joint quality.

- Weather Influence: Unfavorable weather conditions can affect the curing and strength of the masonry joints.

Solutions

To overcome these concerns:

- Using the right mortar mix can mitigate shrinking and cracking risks.

- Proper curing under favorable conditions should be ensured for durable masonry joints.

- Selection of joint type should be based on both aesthetic and environmental suitability.

Advantages of Flush Mortar Joints

Enhanced Aesthetics

Flush mortar joints provide a neat and clean finish to any masonry project. The even surface created by this technique allows for a smoother and more continuous appearance, which can be highly desirable for both modern and traditional architectural styles. This type of joint is especially beneficial when aiming for a minimalist look, where the emphasis is on clean lines and uniformity.

Improved Durability

Flush mortar joints are also known for their increased durability. By filling the joints completely and leveling them with the surface, there’s less room for dust, debris, and moisture to accumulate. This helps in preventing issues like mold growth and efflorescence, which can compromise the structural integrity of the masonry over time.

Easy Maintenance

Maintaining flush mortar joints is relatively straightforward. The smooth surface makes it easier to clean, and since there are no recessed areas, dirt and grime have fewer places to hide. This can be particularly useful in high-traffic areas where cleanliness is a priority.

Weather Resistance

Flush mortar joints provide better resistance to weather conditions. Because the joints are filled and smoothed out, water runoff is more efficient, reducing the likelihood of water penetration and freeze-thaw damage. This makes flush joints particularly useful in climates with heavy rainfall or freezing temperatures.

Enhanced Structural Integrity

By creating a more uniform surface, flush mortar joints contribute to the overall structural integrity of the wall. This uniformity allows for better load distribution and helps the masonry units to act as a single entity, reducing weak spots that could lead to cracks or other issues over time.

What Is the Weakest Mortar Joint?

Introduction to Mortar Joint Strength

In masonry construction, the strength and durability of mortar joints play an important role in the overall stability of a structure. Different types of mortar joints offer varying levels of strength, water resistance, and aesthetic appeal. Understanding which joints are stronger or weaker can help in making informed decisions for different environmental and structural requirements.

Understanding Mortar Joint Weakness

Weak mortar joints are typically those that are less resistant to environmental factors such as water infiltration and extreme temperatures. These joints may also suffer from poor load distribution and have a higher tendency to crack over time. The weakest mortar joint is often considered to be the one where the mortar is recessed from the face of the masonry units, making it more susceptible to weathering and mechanical damage.

| Mortar Joint Type | Strength | Weather Resistance |

|---|---|---|

| Raked Joint | Low | Poor |

| Flush Joint | Moderate | Good |

| Concave Joint | High | Excellent |

| Weathered Joint | High | Good |

Raked Joint: The Weakest Mortar Joint

The raked joint is commonly considered the weakest type of mortar joint for several reasons:

- Recessed Mortar: In a raked joint, the mortar is recessed from the face of the brick, which exposes more surface area to environmental elements. This makes it easier for water to seep in and cause damage.

- Weaker Bond: The recessed nature of the joint means there is less mortar adhering to the brick surfaces. This results in a weaker bond and reduced structural integrity.

- Poor Water Runoff: The recess creates a ledge where water can collect, increasing the risk of water infiltration and freeze-thaw damage.

Comparative Analysis

While flush and concave joints provide better durability, the raked joint falls short in multiple aspects:

- Weather Resistance: Concave and weathered joints effectively direct water away from the masonry surface, enhancing water resistance. Raked joints, however, allow water to pool.

- Structural Support: Flush and weathered joints ensure a stronger bond between bricks. Raked joints, on the other hand, have less contact area and therefore less adhesion strength.

Improving the Weakness

If a raked joint must be used for its aesthetic appeal, consider these improvement techniques:

- High-Quality Mortar: Use a high-quality, flexible mortar mix to compensate for the joint’s inherent weaknesses.

- Sealant Application: Apply sealant to the raked joints to enhance water resistance and protect against environmental factors.

- Regular Maintenance: Regularly inspect and repair any damage to the joints to prevent further degradation.

Summarizing Flush Joints in Construction and Masonry

In conclusion, the art of construction and masonry requires not only skill but also thorough knowledge of various techniques, best practices, and potential challenges.

Flush joints, an important technique, uses different materials like mortar, sealant, and plaster to fill and smooth the joints between two surfaces. It ensures that the seams are less noticeable, while contributing to both the aesthetic and functional aspects of a project.

Furthermore, masonry introduces various other types of joints, such as V joint, weathered joint, concave joint, and raked joint.

Each joint type has its unique strength and application, designed for different aesthetic appeal and environmental conditions. Regardless of type, masonry joint construction encounters challenges including mortar shrinkage and weather influence, which can be mitigated by using proper techniques and materials, as well as ensuring the right joint choice for the situation.

Frequently Asked Questions – FAQs

What exactly is a joint flush in construction?

A joint flush refers to a construction technique where the joints between two surfaces are filled and leveled with a material, resulting in a smooth, even surface. This makes the structure appear continuous and seamless.

What materials are commonly used for a joint flush?

The materials can vary, but commonly include mortar, sealant, and plaster. The choice of material depends on the surfaces being joined and the desired final appearance.

What are the common types of masonry joints?