Unravelling the Concept: Internal Impedance (Battery)

Let’s simplify the term ‘Internal Impedance’ as it relates to batteries. Essentially, it signifies the opposition that a device exhibits to the flow of electric current.

This attribute is crucial in the realm of construction. Batteries power numerous construction tools, with varying levels of internal impedance influencing their efficiency. Determining this factor can provide insights into battery health and longevity.

In a nutshell, understanding internal impedance can help choose the best battery for your construction requirements. It’s all about enhancing performance while predicting maintenance needs.

Understanding the Internal Impedance of a Battery in the Construction World

In the construction industry, the efficiency and performance of machines can be greatly influenced by the condition of their power sources, specifically their batteries. One factor that is often overlooked, yet plays a huge role, is the internal impedance of a battery. This term may sound complicated, but we’re here today to break it down for you into simple, understandable words.

Defining Internal Impedance

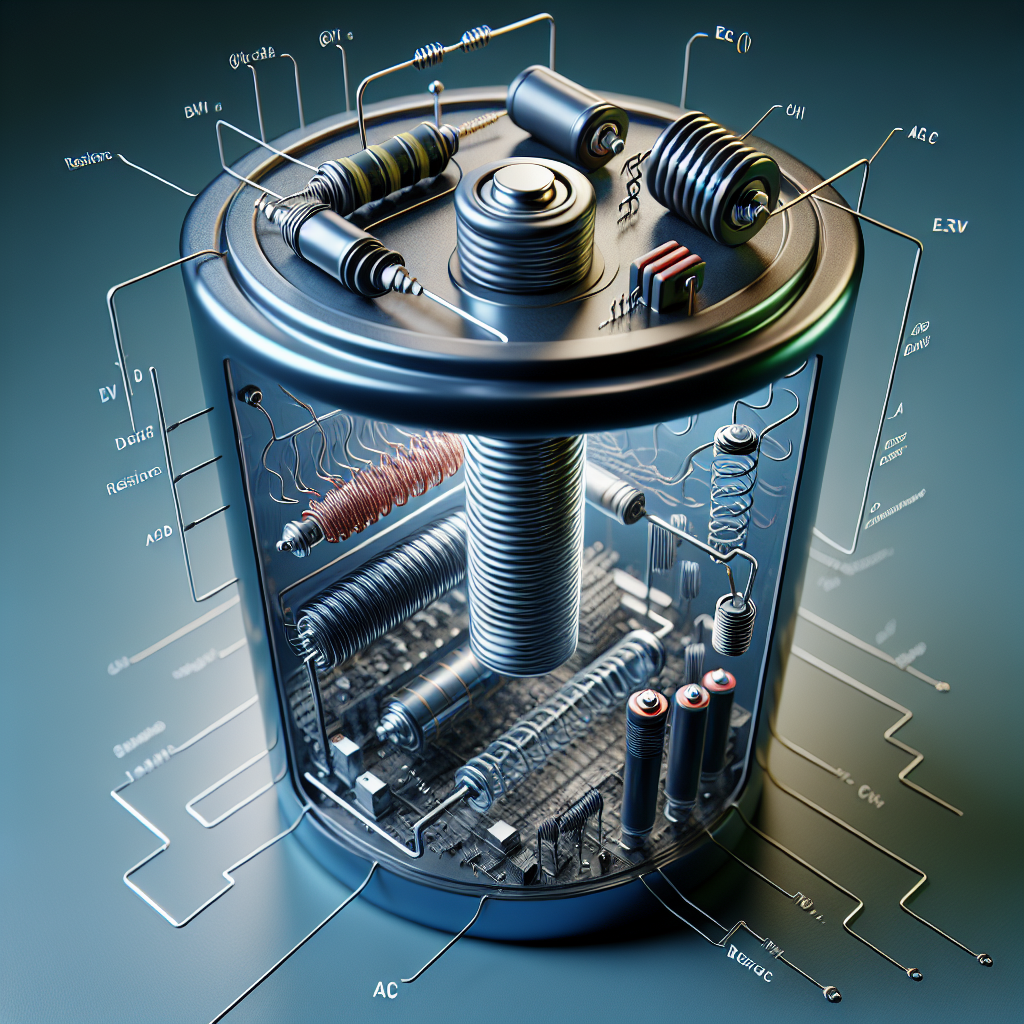

The internal impedance of a battery, in plain English, can be defined as the opposition a battery presents to alternating current (AC). It consists of internal resistance (R), internal reactance (X), and is expressed in ohms (Ω).

Why Does It Matter?

The lower the internal impedance of a battery, the faster it can deliver energy to the load, making it run more efficiently. Therefore, understanding and tracking internal impedance can help predict the remaining life and the overall health of the battery

Factors affecting Internal Impedance

Several factors can directly influence the internal impedance of a battery. To make it easier for you to understand, we’ve listed them below:

- Age and condition of the battery

- Charge level

- Rate of discharge

- Operating temperature

Measuring Internal Impedance

Measuring the internal impedance of a battery is no easy task. It typically requires specialized equipment, as well as knowledge of the specific battery type.

| Procedure |

|---|

| 1. Connect Battery to Specialized Equipment |

| 2. Send an AC signal through the battery |

| 3. Measure the potential difference (voltage) |

| 4. Calculate Internal Impedance |

Understanding and assessing the internal impedance of a battery can be the difference between a smooth-running construction site and one that is consistently delayed by power problems. Gain a comprehensive understanding of how your battery operates, and ensure its well-being for the efficient functioning of your machinery.

For more detailed information, you can refer to the study on battery impedance published by the Journal of Electroanalytical Chemistry (Source).

Digging Deeper into Internal Resistance of a Battery

While internal impedance of a battery is a critical parameter, the concept of internal resistance is an essential part of it. This article will primarily focus on understanding, calculating, and managing the internal resistance of a battery and its impacts in the construction field.

The Concept of Internal Resistance

A battery, despite its simple function, is a complex device. One important characteristic of a battery is its internal resistance which can be roughly defined as the material opposition to the flow of direct current (DC) within the battery itself. It’s a key factor in determining the efficiency and lifespan of a battery. Essentially, the lower the internal resistance, the better the battery’s performance.

Significance of Internal Resistance

A battery with high internal resistance will be less efficient at delivering energy which can cause your machines to run ineffectively. What’s more, higher internal resistance can lead to unnecessary heat generation inside the battery that can potentially cause failures and hazards. Therefore, understanding and managing internal resistance can aid in predicting a battery’s lifespan and maintaining the efficiency of construction machinery.

Factors influencing the Internal Resistance

Besides the factors affecting the internal impedance that we have looked over, internal resistance itself is influenced by certain elements. Here they are:

- The type of battery (e.g., lithium-ion batteries typically have lower internal resistance than lead-acid batteries).

- The state of charge (internal resistance tends to increase as the battery discharges).

- The quality and condition of the battery’s components (batteries with worn out or damaged components tend to exhibit higher internal resistance).

- Size and design of the battery.

How to Reduce Internal Resistance

Reducing a battery’s internal resistance can effectively improve its performance and extend its operating life. Here are some ways to achieve that:

- Proper battery maintenance: keeping the battery clean and well-ventilated can help reduce internal resistance.

- Using batteries with lower impedance designs: Some batteries are specifically designed with low impedance for high-performance applications.

- Controlling the battery’s environmental conditions: Operating a battery within its optimal temperature and humidity range can keep its internal resistance down.

To sum up, understanding the internal resistance of a battery can prevent machine downtime and prolong battery life, enhancing the overall output and safety of your construction activities.

To further enhance your understanding of battery performance, have a look at the book “Electricity and Magnetism” by E Purcell (source), which gives a detailed explanation of the principles behind internal resistance and other battery characteristics.

Taking a Closer Look at Low Impedance Batteries

Now that we have covered the understanding of both internal impedance and resistance, it’s time to specifically look into batteries with the lowest internal impedance. This is vital because low impedance batteries often improve operational efficiency in the construction field.

Top Performing Low Impedance Batteries in the Market

Many batteries claim to have a low impedance, but some clearly stand out in performance. These batteries are typically made with advanced tech and high-quality materials.

- Lithium-Ion batteries (Li-Ion) – Known for excellent energy density and incredibly low internal resistance, these are one of the best choices for high-demand construction machinery.

- Alkaline batteries – Although not as low as Li-Ion batteries, Alkaline batteries offer a relatively low internal impedance warding off machine inefficiencies. However, they are typically non-rechargeable.

Choosing the Right Low Impedance Battery

Choosing the right low impedance battery for your needs can be a challenging task. Several factors must be considered before the final decision:

- Battery type: Different battery types have different levels of internal impedance. As mentioned, Li-Ion batteries have extremely low impedance, making them perfect for high-energy tasks.

- Application requirements: The battery should meet the energy demand of the device it is meant to power. Machines that require a large amount of energy quickly prefer batteries with low impedance.

- Electrical parameters: Ensure that the chosen battery supports the required voltage and current rates for the machine. Incorrect parameters can result in poor performance or harm to the device and battery.

Li-Ion Batteries: The Low Impedance Champion

As repeatedly mentioned throughout the sections, lithium-ion batteries are considered the “King” of low impedance. Their excellent energy density, coupled with a very low internal resistance, allows for rapid energy delivery, making them perfect for high-demand machinery in the construction industry.

Why Choose Li-Ion?

There are two core reasons to choose lithium-ion batteries:

- Unparalleled energy delivery speed: Thanks to their low internal impedance, Lithium-ion batteries can supply power at a very high rate, accommodating the needs of power-hungry machinery.

- Longer life span: Due to the reduced opposition to power flow, Li-Ion batteries do not heat up unnecessarily, therefore experiencing less wear and tear.

Although other batteries like NiMH and alkaline batteries can deliver good performance, they simply do not match the extreme efficiency of Li-Ion batteries when it comes to low internal impedance. Further details regarding this can be found in “Rechargeable Batteries: Materials, Technologies, and New Trends” by Zhengming Zhao (source).

Final Thoughts

Understanding and managing the internal impedance and resistance of batteries can help improve the performance and lifespan of construction machinery. Moreover, making use of low impedance batteries like Li-ion can enhance the overall operational efficiency. Therefore, in the search for the perfect power source, be sure to consider the internal impedance and resistance of the battery.

More on Battery Age and Condition as Factors of High Impedance

As mentioned, the age and condition of a battery significantly affect the internal impedance. In simpler terms, as a battery ages, it naturally develops high impedance. Similarly, a battery not maintained in a good state can develop a high impedance faster. Let’s dive into these aspects a bit more to understand why and how it happens.

Impact of Battery’s Age

Battery age has a pivotal impact on its internal impedance. As batteries age, changes happen in their chemistries. Using a process known as sulfation, toxic lead sulfate crystals form if a lead-acid battery is not fully recharged regularly. These crystals hinder the chemical reactions within the battery leading to higher internal resistance, thereby increasing impedance. This scientific phenomenon has been covered in detail in the “Journal of Power Sources” (source).

Factors Determining the Battery’s Condition

The condition of a battery refers to its current physical and chemical state. Several factors determine the condition of a battery:

- History of charging and discharging

- Degree of sulfation

- Electrolyte levels

- Plate condition

Higher sulfation, poor electrolyte levels, or worn-out plates elevate the internal impedance of a battery, potentially hampering the performance of a battery.

The Role of Charge Level and Rate of Discharge

Charge Level’s Impact on Impedance

A battery’s charge level or state of charge (SOC) directly impacts its internal impedance. Generally, a reduction in SOC results in an increase in impedance. This is crucial to monitor in the construction field as it can greatly affect machine efficiency.

Effects of Charge Level on Different Types of Batteries

Not every battery behaves the same way with SOC. For example, nickel-based batteries show a high impedance at full charge and over-discharge, while lithium-based batteries show a high impedance at a high and low state of charge, i.e., near full discharge and full charge.

Rate of Discharge and Impedance

The impact of the discharge rate on impedance comes from an increase in the battery’s internal temperature. As the rate of discharge increases, the power consumption inside the battery increases, leading to a rise in temperature. This is another way in which the battery impedance rises.

Managing Operating Temperature for Lower Impedance

Another previously discussed factor influencing impedance is the operating temperature of the battery. With optimal temperature control, it’s possible to mitigate high battery impedance effectively.

Optimal Operating Temperatures

The ideal operating temperature for most batteries is around 20°C (68°F). At this temperature, batteries can function at their fullest potential with lower internal impedance.

Temperature Control Techniques

While operating, batteries must be in an environment that falls within their optimal temperature range. Here are some techniques:

- Use temperature-controlled battery compartments in machinery.

- Ensure good ventilation around the battery to avoid overheating.

- Evaluate and maintain the battery cooling systems regularly.

These strategies will help to regulate the internal environment of the battery efficiently, maintaining a lower impedance and enhancing the longevity and performance of the battery.

More detailed discussions regarding temperature influence on battery impedance can be found in “Advanced Batteries: Materials Science Aspects” by Robert Hugginssource.

To Recap

High impedance in a battery is affected by many factors such as the battery’s age and condition, the levels and rate of charge and discharge, and the operating temperature. By keeping an eye on these parameters and optimally managing them, you can mitigate high impedance, ensuring the efficient performance of machinery and equipment in the construction field.

In wrapping up, we’ve found the internal impedance of a battery to be a crucial determinant of its efficiency, particularly in the demanding setting of the construction world. Though the concept can be overwhelming, it essentially relates to how the battery opposes alternating current, thus affecting its energy delivery to the load. It’s worth noting that factors such as age, charge level and operating temperature can directly influence this impedance.

From our perspective, gaining a comprehension of internal impedance and its impact on battery health isn’t just technical knowledge—it’s a strategic advantage. It enables us to foresee potential power challenges, optimize the performance of our machinery and ultimately, keep our construction sites running smoothly. The value of understanding and regularly checking on your battery’s internal impedance cannot be overstressed.

At the end of the day, our machines are as healthy as the batteries powering them. So let’s take steps today to better understand, monitor and improve the health of our construction batteries.