Introduction To Masonry Joints

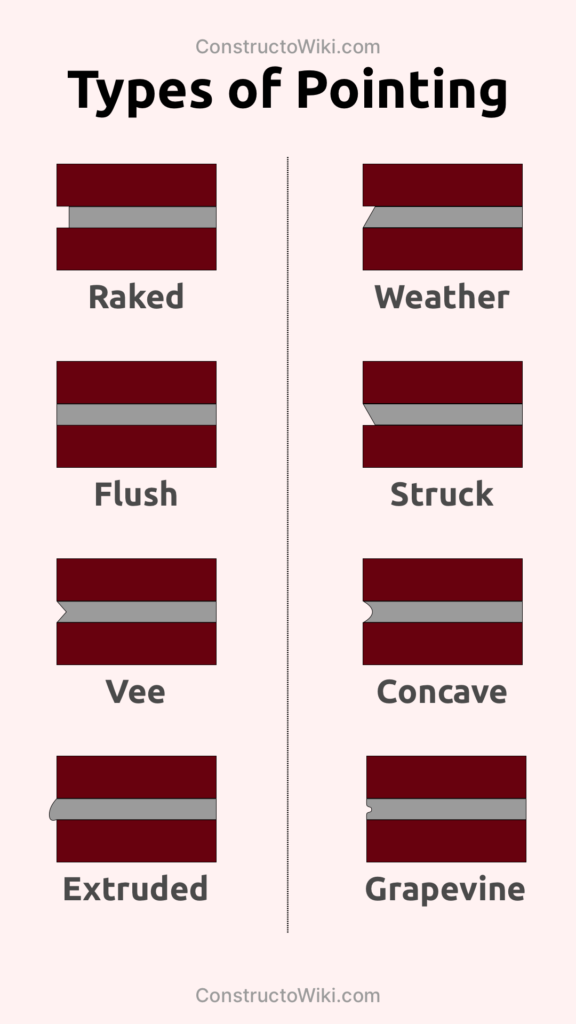

Masonry is an art with a rich palette of techniques, one of which involves the use of different types of mortar joints.

In this article, we’ll unravel the mystery of the bucket handle joint, explore the contrasting raked joint, learn about the weather-resilient weather struck joint, and examine the visually distinct V-joint.

We’ll provide definitions, compare their strengths and weaknesses, and discuss their applications in various construction projects.

Table of Contents

Understanding the Bucket Handle Joint in Construction

Definition and Appearance

A bucket handle joint in masonry is a type of mortar joint finish commonly used in brickwork processes. This joint has a concave finish that resembles the handle of a bucket, providing a subtle curve inward on the mortar line between bricks or blocks.

Creation Process

Tools Needed

- Jointer Tool (with a rounded edge)

- Trowel

- Brush for cleanup

Steps to Achieve a Bucket Handle Joint

- Apply mortar in the joints between the bricks as usual.

- Run the jointer tool along the joints while the mortar is still pliable, pressing it to create the concave shape.

- Ensure consistent pressure for uniformity across all joints.

- Clean up any excess mortar with a brush.

Benefits of a Bucket Handle Joint

Strength: The concave shape helps in shedding water, reducing the chances of water penetration and enhancing durability.

Appearance: This type of joint offers a neat and uniform finish, contributing to the aesthetic appeal of brickwork.

Resistance: It is more resistant to weathering compared to other joint types like the flush or struck joints.

Common Applications

This joint type is popular in both residential and commercial building projects. It is prevalent in exterior walls, garden walls, and any situation where weather resistance is a priority.

Comparison with Other Joint Types

| Type of Joint | Shape | Water Resistance | Application |

|---|---|---|---|

| Bucket Handle Joint | Concave | High | Exterior and aesthetic applications |

| Struck Joint | Downward Angle | Moderate | More common in historic restorations |

| Flush Joint | Flat with Brick | Low | Primarily in interior walls |

Exploring the Raked Joint in Brick Masonry

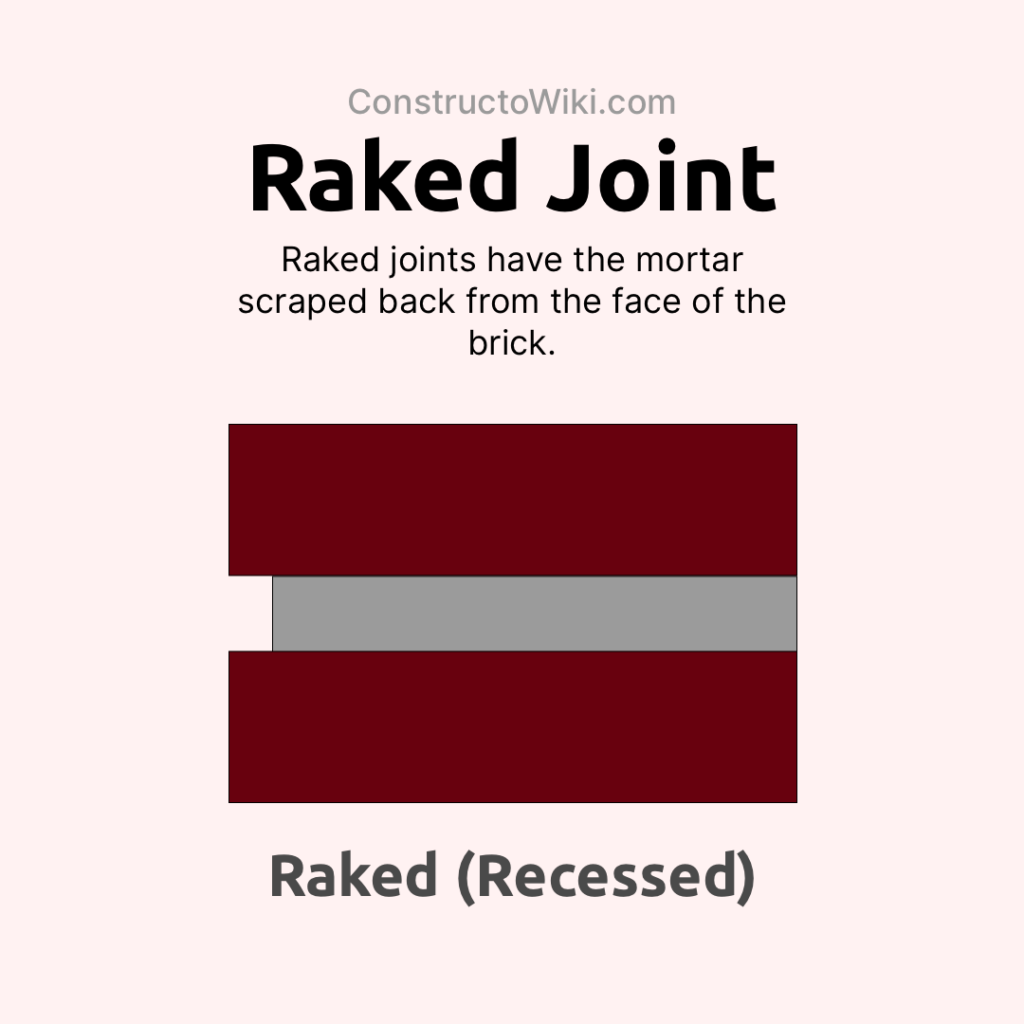

What is a Raked Joint?

A raked joint in brick masonry is a type of finish wherein the mortar is raked or scraped back from the face of the brick. The result is a recessed mortar joint that creates a distinctive shadow line and accentuates the individual bricks.

How is a Raked Joint Created?

Required Tools

- Joint raker or tuck pointer tool

- Wire brush or broom

Steps to Form a Raked Joint

- Mortar is applied between the bricks in the usual manner.

- Once the mortar is thumbprint-hard, use the joint raker or tuck pointer tool to scrape back the mortar approximately 1/4″ from the face of the brick.

- Ensure an even depth across all joints for a consistent appearance.

- Brush away excess debris with a wire brush or broom.

Advantages and Disadvantages of a Raked Joint

Visual Impact: The raked joint accentuates the individual bricks, creating a dramatic visual effect. It enhances the texture and depth perception of the wall.

Increased Vulnerability: Despite its aesthetic value, a raked joint is more susceptible to water penetration due to its recessed nature. Studies show that raked joints can lead to wall degradation, especially in regions with harsh weather conditions.

Areas of Application

Raked joints are often used for interior purposes or in regions with moderate weather conditions due to their decreased water resistance. They are commonly seen in non-load bearing walls, decorative elements, and architectural features where aesthetics are important.

Raked Joint vs Other Brick Joints

| Type of Joint | Shape | Water Resistance | Application |

|---|---|---|---|

| Raked Joint | Recessed | Low | Interior and aesthetic applications |

| Bucket Handle Joint | Concave | High | Exterior and aesthetic applications |

| Struck Joint | Downward Angle | Moderate | More common in historic restorations |

| Flush Joint | Flat with Brick | Low | Primarily in interior walls |

For additional insights into the pros and cons of different types of brick joints, take a look at the resources found on Bricks R Us.

Exploring the Weather Struck Joint in Masonry

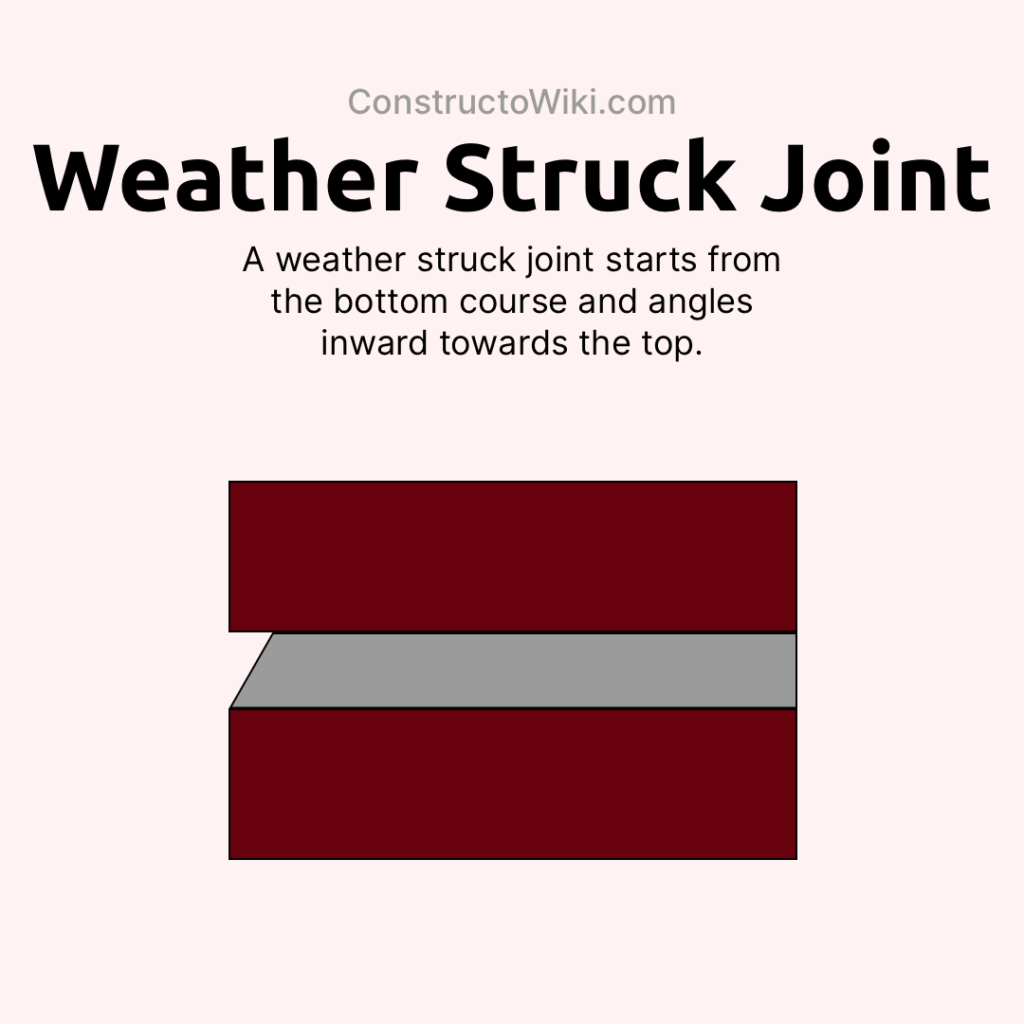

What is a Weather Struck Joint?

A weather struck joint is a form of mortar joint where the top edge of the joint is angled downward and inward, forming a slope. This directional sloping ensures that rainwater is efficiently directed away from the face of the brick, helping to avoid water infiltration that could otherwise compromise the integrity of the wall.

Steps to Create a Weather Struck Joint

Required Tools

- Pointing trowel

- Level or straight edge

- Mortar hawk

- Brush for cleaning up

Creation Process

- Apply the mortar mix into the joints as usual, filling them completely.

- Using the pointing trowel, press the mortar at an angle so the top edge is sloped downward toward the brick. This sloping helps in shedding water effectively.

- Maintain a consistent angle throughout the application for uniformity.

- After the initial set, gently brush away any excess mortar to ensure a clean finish.

Benefits of a Weather Struck Joint

Water Resistance: The downward angle of the joint enhances the wall’s ability to shed water, increasing its resistance to water penetration.

Durability: By reducing water infiltration, this joint type contributes to the overall durability of the structure, minimizing the risks of moisture-related damage like efflorescence and freeze-thaw cycles.

Appearance: When executed proficiently, it gives a sharp, clean look to the brickwork, often preferred for contemporary or modern building designs.

Common Uses

Weather struck joints are a popular choice for exterior walls and any building surfaces exposed to harsh weather conditions. They also find application in garden walls and boundary walls where water drainage is a concern. The functionality and aesthetic appeal of this joint make it suitable for both residential and commercial settings.

Comparison with Other Joint Types

| Type of Joint | Shape | Water Resistance | Application |

|---|---|---|---|

| Weather Struck Joint | Angled Downward | High | Exterior walls, boundary walls |

| Bucket Handle Joint | Concave | High | Exterior and aesthetic applications |

| Struck Joint | Downward Angle | Moderate | More common in historic restorations |

| Flush Joint | Flat with Brick | Low | Primarily in interior walls |

Understanding the V-Joint in Brick Masonry

What is a V-Joint?

A V-joint, also known as a weathered or weather-struck V-joint, is a type of mortar joint where the mortar is shaped into a noticeable “V” shape, recessed at the center and pointing outward. This profile aids in rainwater runoff, preventing water retention and potential damage to the masonry.

How is a V-Joint Created?

Required Tools

- Pointing trowel with a V-shaped tip

- Level or straight edge

- Mortar board

- Brush for cleanup

Creation Process

- Apply the mortar into the joints as usual, ensuring the joints are fully filled.

- While the mortar is still pliable, use the V-shaped trowel to create a concave V-profile by running the tool through the joints.

- Maintain consistent depth and profile across all joints to ensure uniform appearance and function.

- Clear any excess mortar using a brush once the joints are partially set.

Benefits of a V-Joint

Water Resistance: The V profile effectively channels water away from the brick face, reducing water infiltration.

Durability: By preventing moisture buildup, the V-joint helps to extend the lifespan of the masonry structure.

Visual Appeal: The distinct shape adds a decorative element to brickwork, enhancing its overall aesthetics.

Common Applications

V-joints are typically employed in exterior walls and structures where enhanced water runoff is crucial. They are favored in garden walls, retaining walls, and facades subject to heavy rain or severe weather conditions, combining functionality with added visual detail.

Comparison with Other Joint Types

| Type of Joint | Shape | Water Resistance | Application |

|---|---|---|---|

| V-Joint | Concave V | High | Exterior walls and decorative uses |

| Weather Struck Joint | Angled Downward | High | Exterior walls, boundary walls |

| Bucket Handle Joint | Concave | High | Exterior and aesthetic applications |

| Struck Joint | Downward Angle | Moderate | More common in historic restorations |

| Flush Joint | Flat with Brick | Low | Primarily for interior walls |

Conclusion: The Role of Different Joint Types in Masonry

In summary, masonry involves much more than simply laying and arranging bricks or blocks.

The type of mortar joint selected plays a significant role in both the visual appeal and functional durability of the structure. The Bucket Handle Joint, popular for its water-shedding ability, and the pleasing aesthetic of the Raked Joint, despite its increased vulnerability to water, are both prime examples.

We covered the Weather Struck Joint and its defensive downward angling against water infiltration as well as the recessed V-Joint, often used in harsh weather conditions for its effective water channeling.

Each of these joint types possesses unique characteristics. Their selection and application depend on various factors such as location, weather conditions, and the desired aesthetic look.

Frequently Asked Questions – FAQs

What factors should be considered when selecting a joint type for masonry?

Primary factors to consider include the type of structure, its location, prevailing weather conditions, and the desired aesthetic outcome.

Which joint type is best for weather resistance?

While every situation is different, the Bucket Handle Joint, Weather Struck Joint, and V-Joint are all known for their weather resistance and water-shedding properties.

Are certain joints better for particular visual looks?

Yes. For instance, the Raked Joint accentuates individual bricks, creating a dramatic visual effect, while the V-Joint adds particular decorative detail to a structure.

What joint is often used in historical restorations?

The Struck Joint, with its downward angle, is often used in historical restorations.