Pushing Boundaries with Remote Control Points

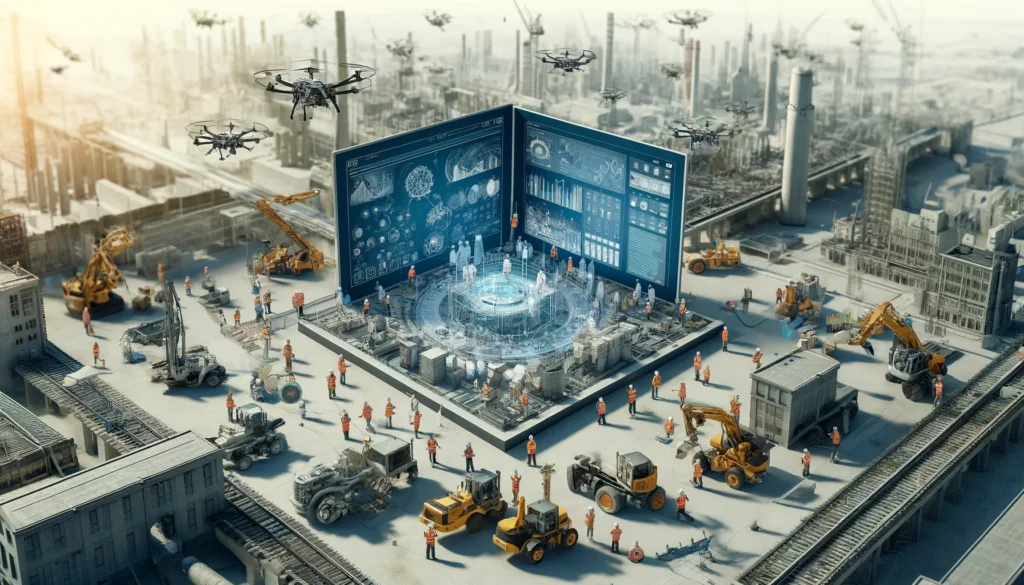

Can you imagine construction sites that hum with the precision of a well-rehearsed ballet rather than the chaos that is traditionally associated with them?

That future is here, thanks to the advent of Remote Control Points (RCPs).

RCPs have proven to be game-changers in the construction field. Machines operating in harmony with each other, seamlessly completing tasks assigned to them, all under the watchful eye of an operator at a safe distance.

No more human lives at risk, no more errors due to hand-operated machinery.

The power of RCPs lies in their ability to control machinery on construction sites from afar, thereby improving safety, efficiency, and precision.

It’s a far cry from the perilous and unpredictable scenarios workers often faced in the past.

Ready to explore how this advancement is reinventing the construction industry?

Let’s tune in.

Table of Contents

The Tool Changing Construction Sites

When you walk by a construction site, chances are you’ve seen large machines drilling holes or moving rocks.

But did you know that some of these machines might not even have a human operator inside them?

That’s right – welcome to the world of Remote Control Points (RCPs).

Your Guide to Remote Control Points

Remote Control Points unlock a new level of efficiency and safety in construction. By allowing construction machines to be controlled remotely, they not only reduce the risk to human operators, but also offer advantages in terms of precision, efficiency, and productivity.

Breaking Down the Concept

Let’s make sure we’re all on the same page when it comes to what actually constitutes a Remote Control Point.

- Remote: This part of the term refers to the ability to operate the tool or machine from a distance, whether that be a few feet or miles apart. It’s the same concept as using a TV remote from the comfort of your couch.

- Control: This indicates the ability to dictate the machine’s operations – to start, stop, move, or perform certain tasks.

- Point: This term might be a little confusing. It doesn’t refer to a physical location, but rather the source of the control – the device in the operator’s hand or the computer at their desk.

Getting Practical with RCPs

Now that you know the basics of what a Remote Control Point is, let’s take a look at how they’re deployed in the field.

Types of Machines Using RCPs

Remote Control Points are being incorporated into numerous types of construction machines. Let’s take a look at some of the most common:

- Demolition Robots

- Excavators

- Drilling Rigs

- Crushers

- Loaders

The Power of RCPs in Solving Problems

RCPs have been a game changer for the construction industry, solving a number of challenges facing modern construction sites.

| Problem | Solution |

|---|---|

| Worker Safety | By allowing operators to control machines from a safe distance, RCPs reduce the risk of accidents and injuries. |

| Efficiency and Productivity | RCPs allow for seamless operation of machines, cutting out downtime and improving productivity. |

| Precision | The precise controls of an RCP ensure accurate task execution, minimizing errors and reducing waste. |

Remote Control Points have revolutionized construction, making it safer, more efficient, and more precise. So, next time you pass by a construction site, take a moment to appreciate the high-tech wizardry at work.

Remote Control Points in Construction Networks

A stroll past a construction site at present showcases not just the traditional symphony of swinging cranes and buzzing jackhammers, but a slew of smart machines operating independently – or seemingly so.

These units, controlled by Remote Control Points (RCPs), symbolize the advent of networked construction and the incredible leaps technology has helped the industry take.

Digging Deeper into Remote Control Points

While our forefathers in construction worked under considerably more precarious conditions, the era of advanced technology and automation brings the promise of safer, faster, and more efficient results.

Let’s go into how RCPs make this a reality.

RCPs: Tech Titans in Tiny Packages

Just as a television remote control governs channels, volume, and more while you lounge on your best-loved spot on the sofa, a Remote Control Point in construction directs the functionalities of a machine, albeit from a greater distance and with far more precision.

Here are the inner workings:

- The Remote: Inclusively, this aspect can operate over “short and sweet” distances (a few feet, perhaps) or substantial separations (possibly miles), leading a digital dance between the operator and the machinery.

- The Control: The pulse of the term, this element facilitates manipulation of a machine’s start, stop, movement, and task protocols. It’s the rhythm to the “remote’s” melody – the brains behind the brawn.

- The Point: Surprisingly, this doesn’t refer to a physical point per se but symbolizes the “Alpha” of the process – the handheld device or operator’s computer setting the remote-control dance into motion.

Deploying RCP Magic on Site

Having outlined what an RCP stands for and its functionality, let’s bring the concept down to the ground and observe its application in the construction field.

Construction Machinery and RCP Harmony

In practice, Remote Control Points seamlessly integrate themselves into several types of construction machinery, playing pivotal roles in tasks ranging from simple to complex:

- Pile Boring Rigs

- Concrete Mixers

- Material Handlers

- Laser Screed Machines

- Backhoe Loaders

Bringing Resolution with Remote Control

RCPs have sprung onto the construction scene as a problem-solver par excellence, tackling numerous issues plaguing contemporary construction zones.

| Problem | Solution |

|---|---|

| Hazardous Operations | RCPs allow for the safe maneuvering of dangerous tasks, reducing the risk of life-threatening situations. |

| Operational Errors | Through precision in operations, RCPs significantly lower the risk of costly mistakes or inefficiencies. |

| Waste Reduction | By cutting back on errors, RCPs also reduce resource waste, leading to a more sustainable operational mode. |

Remote Control Points, paired with adept human operators, present an unrivaled technological advancement in the construction industry. Witness this marvel the next time you navigate past a construction site buzzing with efficient, precise, and safe activity, all thanks to RCPs.

Linking Devices to a Remote Control Point: A Construction Game-Changer

The wonder of Remote Control Points (RCPs) doesn’t end with their use in controlling machinery on construction sites. Adding to the magic, an impressive range of devices can be linked to RCPs, opening up new dimensions of efficiency, safety, and effectiveness.

The Mechanics of Device-to-RCP Connectivity

In the realm of networked construction, the potential of Remote Control Points reaches its pinnacle when linked to varied devices. Before delving into specifics, let us understand the core principle of this connectivity.

Technological Symphony – when Devices meet RCPs

Inter-connectivity between different devices and RCPs is orchestrated by network protocols and software programming. Essentially, the device and the RCP should understand the same ‘language’ – the transmission protocols – for this interaction to occur. This ‘dialogue’ between the connected devices and the RCP facilitates seamless command execution, enhancing productivity on the construction site.

Array of Devices that pair well with RCPs

Now that we have a grip on the fundamental concept, let’s uncover the types of devices that can get hooked up with RCPs in the construction field.

The RCP-Compatible Device Library

In a world where technology knows no bounds, a variety of devices can be connected to RCPs to maximize their utility. Here are some examples:

- Handheld Remote Control Devices

- Laptops or Desktop Computers

- Tablets and Smartphones

- Specialty Devices (such as joysticks)

- Sub-control boards (for complex machinery)

Enhancing Construction Outcomes with Linked Devices

Each of these devices, when linked to an RCP, brings unique advantages to the table, transforming the way construction tasks are planned and executed.

| Device | Benefit |

|---|---|

| Handheld Remote Control Devices | Provides mobility and ease of use for operators. |

| Laptops or Desktop Computers | Promotes precise control over complex tasks with diverse functionalities. |

| Tablets and Smartphones | Enables monitoring and control on the go, improving responsiveness. |

| Specialty Devices | Allows for specialized control requirements (like maneuvering complex machinery). |

| Sub-control Boards | Facilitates controlling multiple machines simultaneously, augmenting productivity. |

The universe of Remote Control Points has expanded far beyond being merely a remote control for machinery. By embracing interconnectivity with a plethora of devices, RCPs are reshaping the construction landscape with every drill, every move, and every stone turned.

Tinkering with Troubles in Remote Control Points

Like any sophisticated technology, Remote Control Points (RCPs) may hit occasional hitches. However, don’t fret! In this age of technological advancement, pragmatic solutions are within your grasp and understanding these common problems can make all the difference.

Cracking the Code of Remote Control Point Problems

Emerging from the shadows of traditional construction methods, RCPs have simplified construction tasks but also brought their own set of unique challenges. Let’s begin by identifying these issues.

RCP Troubles Unlisted

From myriads of potential difficulties, certain issues with Remote Control Points make frequent appearances. Here’s a glimpse:

- RCP Connectivity Interruptions

- Command Transmission Delays

- Machine Misoperations

- RCP Device Malfunctions

Dissecting Remote Control Point Difficulties

Now that we’ve outlined these common difficulties, it’s time our journey took us deeper into the root of these problems, ensuring we’re equipped to tackle them head-on.

Scenarios Behind Common RCP Problems

Drilling down into the identified issues can help us understand the common contributing factors, bringing us one step closer to resolution:

- For Connectivity Interruptions: Insufficient signal range or physical obstructions between the operator and the machine can disrupt RCP connectivity.

- For Transmission Delays: The latency in command execution might be attributed to network lags or system overloads.

- For Machine Misoperations: This could be due to inaccurate commands being sent due to operator error or software glitches.

- For RCP Device Malfunctions: Physical damages or internal faults in the controller device can electively cause malfunctions.

Debugging Your Way Out

With a clear understanding of potential problems and their origins, we’re now ready to roll up our sleeves and dive into problem-solving.

Turning Problem into Progress: RCP Troubleshooting Tips

Armed with knowledge and some proactive strategies, let’s tackle these common RCP challenges one by one and transform complications into progression.

Solving Connectivity Interruptions

If your RCP is struggling with connectivity, check the following:

- Confirm the operational range of the RCP.

- Ensure there are no physical obstructions between the operator and machine.

- Make sure the operator device and machine are properly charged and powered on.

Tackling Command Transmission Delays

When faced with transmission delays, these steps may come handy:

- Verify the network’s speed and stability.

- Ensure that the system is not overloaded with tasks.

- Consider deploying commands at non-peak times to reduce network congestion.

Addressing Machine Misoperations

If your machinery is not operating as expected, these actions may be useful:

- Make sure the commands given are accurate and complete.

- Perform a system check to identify potential software glitches.

- Ensure the operator is adequately trained and familiar with the machine’s operation.

Fixing Device Malfunctions

Finally, in the event of device malfunctions:

- Check for visible physical damage to the device.

- Ensure the device is appropriately charged and powered on.

- Contact the manufacturer or a professional for repair or replacement if necessary.

With this toolkit of solutions, you’re now ready to face the challenges that may come your way with RCP operations. With every obstacle, remember there’s an opportunity for learning and improvement. So, keep pushing forward, confident in your ability to handle and surmount Remote Control Point obstacles as they come.

Wrapping Up: The Promise of Remote Control Points

As we’ve explored, Remote Control Points are reshaping the face of the construction industry. Boosting efficiency, bolstering safety and amplifying productivity, these technological marvels are making their concrete mark in the field.

They’re not just dictating machine operations – they’re dictating a new era of construction, sweeping in much-needed change.

Games are no longer limited to the screen, they’ve found their playground in the construction arena, turning workers into remote operators guiding their players – our machines.

So, the next time you see a construction site with machines buzzing around, just remember – it’s not just a site, but a glimpse into an innovative future forged by the likes of Remote Control Points.