Demystifying Induced Current in Construction

An interesting term often heard in the construction field is “Induced Current.” This term refers to the generation of an electric current in a conductor due to the changing magnetic field around it.

How does this apply in construction, you might ask? Well, it is an essential principle when designing and installing electrical systems in buildings.

Part of the construction process is ensuring that such systems are correctly installed to prevent electrical interference or system failure due to induced currents.

Understanding Induced Current in the Construction Field

Understanding the concept of induced current within the construction realm isn’t as complex as it might initially seem when broken down into simple terms. Let’s dive into what it means and how it impacts construction.

What is Induced Current?

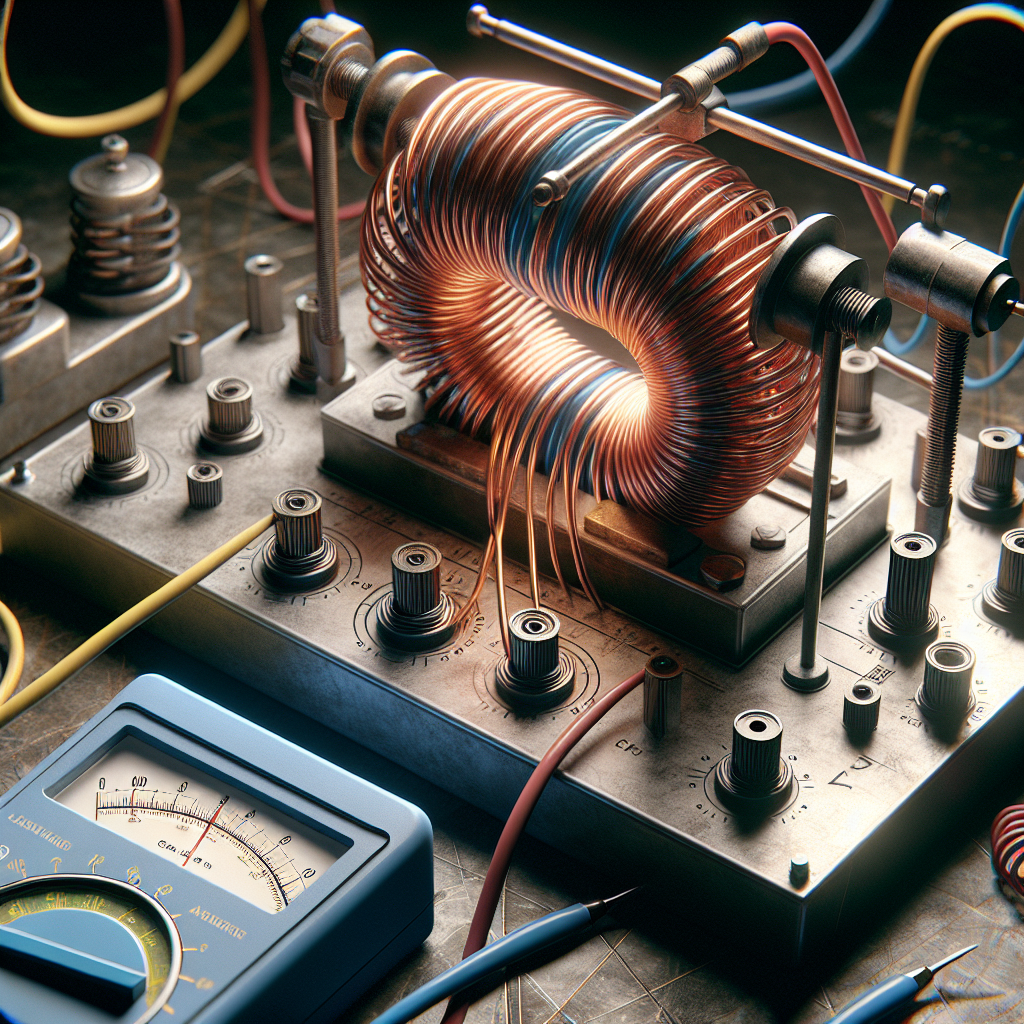

When we talk about induced current, we’re essentially discussing how a change in a magnetic field within a closed loop of wire can produce or ‘induce’ a current. This occurrence is also referred to as electromagnetic induction, a principle closely linked to the operation of many devices used in construction work.

The Science Behind Induced Current

You might recall from your high school physics class Faraday’s Law of Electromagnetic Induction. Michael Faraday, a scientist in the 19th century, discovered this principle, stating that a change in the magnetic field within a loop of wire induces an electromotive force (EMF) in the wire[1](http://hyperphysics.phy-astr.gsu.edu/hbase/electric/farlaw.html). In simpler terms, you can generate electricity using magnetism and some wire – that’s induced current!

Role of Induced Current in Construction

Although it may seem a bit too far into the realm of physics, the concept of induced current isn’t just theory; it’s a practical principle used in various construction applications.

Power Tools

Power tools used in construction primarily operate on the principle of electromagnetic induction. Drill machines, power saws, and concrete vibrators are all examples where induced current plays a fundamental part. These tools use electromagnets and a rapidly changing magnetic field to produce a powerful, controlled current.

Electromagnetic Testing

In the construction industry, nondestructive testing methods often leveraged include Electromagnetic Testing (ET). These methods use induced current to inspect the integrity of materials and structures, helping contractors identify any potential issues early.

Utility Detection

Finding hidden utilities without causing damage is critical within construction. The industry uses ground-penetrating radar equipment that leverages induced current to locate buried utilities, ensuring a safer excavation process.

Takeaway

Even if you didn’t realize it, the principle of induced current is at work in many familiar construction scenarios, from the operation of your power tools to the integrity checks via nondestructive tests. Understanding this concept can enhance your knowledge of these everyday tools and methods, improving safety and efficiency on the job site.

Induced Current: AC or DC?

The nature of induced current, whether it’s AC (Alternating Current) or DC (Direct Current), is a common question when taking a deeper look into this subject. Let’s explore the concept further to clarify the distinction.

Understanding AC and DC

At the most fundamental level, AC and DC represent different methods by which electricity flows.

AC (Alternating Current)

AC is the type of electricity in which the direction of electric charge periodically reverses. This type of current is used prominently in households and business establishments, most notably to power appliances. Its chief benefit lies in its ability to change voltage levels easily, which is essential for long-distance transmission[2](https://www.energy.gov/articles/war-currents-ac-vs-dc-power).

DC (Direct Current)

On the other hand, DC, as the name implies, is electricity that flows in a constant direction. It’s frequently used in low-voltage applications such as battery-operated devices. DC is most famous for powering small devices like remote controllers, flashlights, and electric vehicles.

Induced Current: AC or DC?

Here lies the answer to our original question: is induced current AC or DC?

To put it simply, the nature of the induced current depends on the magnetic field changes. If the magnetic field changes polarity (direction) periodically, i.e., it alternates, the induced current is AC. However, if the magnetic field changes in intensity but remains unidirectional, the induced current is DC[3](https://www.physicsforums.com/threads/ac-or-dc-magnetic-field-induces-ac-or-dc-current.657939/).

Effects on Construction Applications

The alternating or direct nature of induced current doesn’t change much in terms of its practical application in the construction industry. Construction devices designed to utilize induced current — from power tools to detection equipment — work effectively regardless of whether the current is AC or DC. The engineers designing these devices take care to use components that are appropriate for the type of current used.

Takeaway

Understanding whether the induced current is AC or DC is as simple as analyzing the nature of magnetic field changes. While the theory may seem complex, its applicability in construction remains constant and practical, driving the functioning of several essential tools and devices. If you’re working with or creating devices that utilize induced current, understanding these concepts can contribute significantly to crafting more efficient and reliable tools.

Induction Transformers in Construction

Diving deeper into the implications of induced current in the construction industry, let’s shed some light on a device that’s quite omnipresent yet often overlooked – transformers. More specifically, let’s discuss induction transformers and their role in powering our construction sites.

What are Induction Transformers?

Induction transformers, also known as magnetic transformers, work under the same principle of electromagnetic induction. They transfer electrical energy from one circuit to another through the process of electromagnetic induction[4](https://www.electronics-tutorials.ws/transformer/transformer-basics.html). These transformers often step up (increase) or step down (decrease) voltage levels as per requirements, ensuring a safe and efficient distribution of power.

Construction Sites and Induction Transformers

Construction sites are complex environments where power tools, lighting, machinery, and other electrical needs coexist. Given the high energy demands and safety concerns, stable and well-controlled electricity supply is crucial. Here, induction transformers play a crucial role.

Safe Voltage Levels

Construction sites feature a mix of equipment, each with different voltage requirements. Induction transformers help to adjust the voltage supply accordingly, ensuring that the connected devices receive suitable electrical levels. They effectively step down high voltages to safer levels for use in tools and appliances[5](https://www.electrical4u.com/transformer-basics-and-transformer-principles/).

Isolation and Protection

Induction transformers, particularly isolation transformers, can provide an additional level of safety on construction sites. They separate primary and secondary circuits physically, helping control possible electrical faults or reduce ground loops, which can be harmful to both operators and equipment[6](https://www.americantechsupply.com/Isolationtransformers.htm).

Inductive Power Transfer

Another exciting aspect of induced current in construction lies in inductive power transfer (IPT). This technology enables wireless energy transfer based on the principle of electromagnetic induction. Though still nascent, IPT has immense potential in construction, for example, in charging of battery-operated tools or even wireless power transfer for mobile machinery.

Wireless Charging of Tools

In construction sites, where finding a nearby power outlet can be a challenge, wireless charging of battery-operated tools can be a boon. By positioning the tool over a designated charging surface, the device recharges automatically without requiring connectors or cables. The system operates thanks to the electromagnetic fields between the tool battery and charging pad[7](https://www.sciencedirect.com/science/article/pii/S2352484716301259).

Potential Future Applications

While the technology is still emerging, we can anticipate other future applications within construction. For example, the induction-based wireless power transfer might be explored for powering small construction bots or autonomous vehicles on site, adding another layer of efficiency and adaptivity[8](https://www.nist.gov/sites/default/files/documents/el/isd/subcommittee-Reports/2019-24-1-F_Group1_Inductive_Power_Transfer_Interoperability.pdf).

Takeaway

Embracing induced current in the form of induction transformers or inductive power transfer can open up new possibilities within the construction industry. It’s another testament to the versatility of this physical phenomena and its real-world implications. By understanding these principles, construction industry personnel can harness these technologies to create safer and more efficient work environments.

Induction Cooking and Induced Current

While the construction industry heavily employs the concept of induced current through tools and transformers, this principle has found application in a unique and perhaps surprising field: induction cooking.

What is Induction Cooking?

Induction cooking refers to a cooking method that uses magnetic fields to heat cookware directly, rather than through an electric or gas-burning heat source[9](https://www.explainthatstuff.com/induction-cooktops.html). This cooking method owes its effectiveness and efficiency to the principle of electromagnetic induction, the same physics concept we’ve been exploring.

How Does Induction Cooking Work?

In an induction cooktop, an electromagnetic coil beneath the glass surface produces a magnetic field when the appliance is turned on. When compatible cookware is placed atop the induction burner, the fluctuating magnetic field induces an electric current in the cookware’s material. This current causes resistance, leading to heat within the cookware that cooks the food[10](https://www.finecooking.com/article/how-induction-cooking-works).

This might seem quite different from power tools and transformers but the concept beneath, i.e., “electric current produced due to change in magnetic field” is the universal principle that binds these diverse applications.

Induction Cooking in Commercial Construction

Commercial establishments like restaurants, cafeterias, and catering services often use induction cooking. It provides several benefits that make it an attractive choice in commercial kitchens:

Efficiency

Because the induced current directly heats the pot or pan, not the cooktop, less heat is lost to the environment. This makes induction cooking more energy-efficient, which is a valuable trait in commercial settings where extensive cooking takes place[11](https://www.energy.gov/eere/buildings/building-technologies-office).

Safety

As the cooktop itself remains reliable, the chances of burns or other heat-related accidents are significantly reduced, providing a safer cooking environment[12](https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4121912).

Speed

Induction cooking heats food faster because of the direct transfer of heat. The elimination of intermediary heating steps lets establishments serve food more quickly, a crucial factor in the food industry.

Induction Cookware Required

Just as specific power tools and transformers are needed to make effective use of induced current in the construction industry, induction cooking also demands compatible cookware. The pots and pans must contain iron, an inductive material, to effectively respond to the electromagnetic field from the cooktop. Therefore, kitchen utensils comprised of materials like glass, ceramic, or copper are typically unsuitable for induction cooking[13](https://www.sciencedirect.com/science/article/abs/pii/S0306456515001301).

Takeaway

The principle of induced current stretches far beyond the boundaries of the construction domain into everyday areas like cooking. Understanding the theory and applications of induced current can empower us to make informed decisions, whether in selecting efficient cooking methods or building safer workspaces. As explored with induction cooking, induced current continues to shape our daily routines in innovative, efficient, and practical ways.

In conclusion, induced current, or electromagnetic induction, plays a pivotal role in the construction industry’s day-to-day operations.

From powering various necessary power tools such as drill machines and concrete vibrators, to nondestructive inspection methods like Electromagnetic Testing (ET), and even in the vital process of utility detection, the science of induced current is at the core.

In our experience, understanding this principle refines not only the understanding of these common tools and methods, but also enhances safety and efficiency on the job site. From our perspective, the concept of induced current isn’t just a theory; it’s indeed a practical pillar underpinning multiple construction applications.