Introduction to Vacuum Interrupters and Their Utility

Ever wondered why it isn’t lights out each time there is an electrical malfunction within the grid?

That, my friend, is thanks to ingenious devices like vacuum interrupters. They’re like the superheroes of the electrical world, swooping in to prevent potential disasters. But what exactly are these devices, and how do they contribute to the smooth operation of our electrical systems?

In this article, we’ll explore the world of vacuum interrupters, filled with arcs, vacuum-sealed chambers, and electrical contacts. We’ll explain what they are, how they work, their key components, as well as where and why they’re used, including cost-effectiveness and environmental impact.

Additionally, we’ll shed light on their close relatives—the vacuum fault interrupters (VFIs), explain their functionality, and categorize the different types of interrupters in use.

Let’s hit the switch and get into it.

Table of Contents

What is a Vacuum Interrupter?

Understanding the Basics

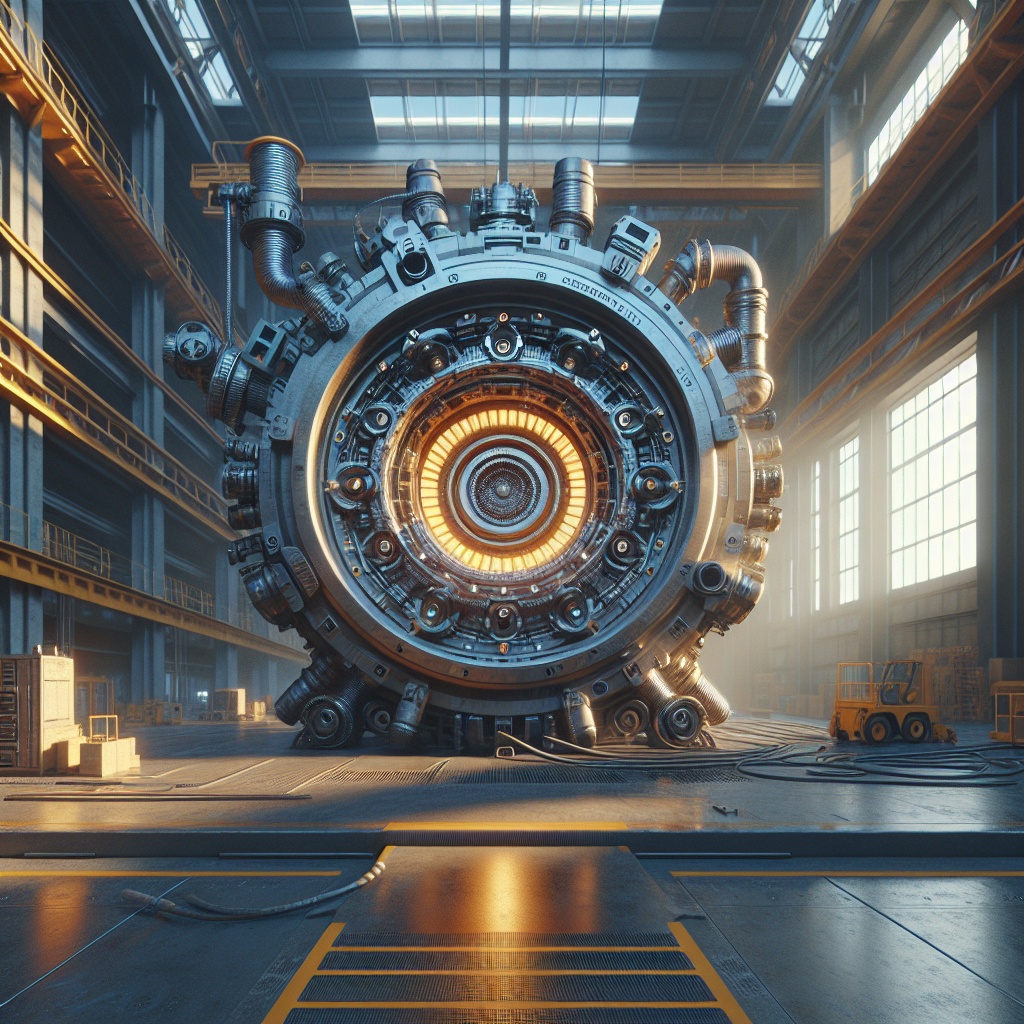

A vacuum interrupter is a device used in electrical switchgear to provide short-circuit protection and load switching. It utilizes a vacuum to extinguish the electrical arc that occurs during circuit interruption.

How It Works

Arc Quenching

In conventional interrupters, an arc is formed when the circuit is broken. Here’s how a vacuum interrupter handles it:

- The contact points within the interrupter are separated.

- An arc forms between the contacts.

- The vacuum environment removes any ionizable material, quenching the arc.

Components

A typical vacuum interrupter consists of several key elements:

| Component | Function |

|---|---|

| Interrupter Chamber | Houses the contacts in a vacuum-sealed environment. |

| Contacts | Open and close to allow or interrupt electrical flow. |

| Arc Shield | Protects the chamber walls from the arc. |

Applications

Vacuum interrupters are commonly found in:

- Medium voltage circuit breakers

- Load break switches

- Reclosers

Advantages of Vacuum Interrupters

Reliability

Vacuum interrupters offer high reliability due to fewer moving parts and a sealed environment. They require less maintenance compared to other interrupters.

Environmentally Friendly

Since vacuum interrupters do not need gas or oil for arc quenching, they pose less risk to the environment.

Cost Efficiency

Due to their durability and low maintenance requirements, vacuum interrupters can be cost-effective over their lifespan.

For additional detailed information, you can learn more about vacuum interrupters from Electronics For You.

The Design of a Vacuum Interrupter

The Creation of Vacuum

The key to the function of a vacuum interrupter lies within its vacuum-sealed chamber. This enclosed space is purposely void of any gas molecules, which prevents any potential for conduction. Producing a high-quality vacuum in an interrupter is a complex process involving precise craftsmanship.

Evacuation and Sealing

The chamber is initially filled with gas or air during assembly. It’s then subjected to a process known as evacuation, where the gas or air is sucked out by a vacuum pump. Following this, the chamber is permanently sealed to maintain the vacuum environment.

Importance of Contact Material

The contacts play an integral role in the function of a vacuum interrupter. The material used to manufacture these contacts significantly affects the performance of an interrupter. Among the popular materials are copper and chromium, praised for their low melting points and good thermal conductivity.

The Use of Copper-Chromium Contacts

Copper-chromium (CuCr) is a common material used in the contacts of vacuum interrupters. The advantages of this material lie in its unique characteristics:

- Excellent electrical and thermal conductivity: This ensures a quick heat dissipation, preventing any potential damage to the interrupter caused by the heat produced during arcing.

- Low chopping current: CuCr contacts, due to their low chopping current, reduce the possibility of secondary arcing, promoting a more efficient and safe operation.

Vacuum Interrupter in High Voltage Settings

Use in High Voltage Circuit Breakers

While vacuum interrupters are often found in medium voltage applications, they are also used in high voltage circuit breakers. The vacuum technology contributes to the reduction of the potential impact on the environment, given the reduction in the use of Sulphur hexafluoride (SF6) gas, which is typically used in high voltage switchgear and is a potent greenhouse gas.

Operation in High Frequency Situations

Vacuum interrupters also operate seamlessly under high-frequency conditions due to their fast response times. Their minimized arc duration contributes to reducing the thermal effect on the system, ensuring stable operation during a fault occurrence.

With these properties, vacuum interrupters prove to be a highly efficient tool for managing complex electrical operations in various settings, from power supply utilities to factories and transportation. To appreciate their breadth of application, one can learn more about their usage in high pressure and medium voltage applications in this IEEE research paper.

The Function of a Vacuum Fault Interrupter (VFI)

Short-Circuit Protection and Load Switching

Vacuum fault interrupters (VFIs) are specialized devices within electrical systems that ensure the fault management is versatile and efficient. They provide both short-circuit protection and load switching capabilities.

Core Functions of VFIs

Short-Circuit Interruption

VFIs are essential for interrupting high current flows that occur during short-circuits. This prevents potential damage to the electrical system and ensures safety:

- Upon detecting a short-circuit, the VFI immediately separates its contacts.

- Similar to standard vacuum interrupters, an arc forms between these contacts.

- The vacuum in the chamber quickly extinguishes this arc, interrupting the current flow.

Load Break Switching

Load break switching allows the VFI to handle and interrupt normal load currents:

- When load switching is required, the VFI separates the contacts under lower current conditions compared to a short-circuit.

- The vacuum environment ensures that the arc is successfully extinguished even with smaller currents.

Emergence of Advanced Features

Fault Detection Mechanisms

Modern VFIs often come with sophisticated fault detection algorithms that enhance their effectiveness in grid management. These algorithms can differentiate between temporary and permanent faults, reducing downtime and improving reliability.

Improved Operational Safety

VFIs contribute to enhanced safety in electrical systems due to their enclosed, arc-free operation. The elimination of explosive gases or harmful chemicals makes them suitable for sensitive environments.

Impact on Grid Reliability

VFIs add a level of redundancy and reliability to the electrical grid by promptly addressing faults and switching operations. This minimizes the risk of prolonged outages and equipment damage.

| Component | Function |

|---|---|

| Fault Sensor | Detects abnormal currents and signals the interrupter to operate. |

| Controller | Processes fault data and commands the interrupter to open or close. |

| Actuator | Executes the open or close action of the contacts. |

Broader Use Cases for VFIs

Protection in Utility Networks

VFIs are commonly employed in utility distribution networks where they protect transformers and feeders. They allow for the continuous management of electrical flows even under fault conditions.

Industrial Applications

In industrial settings, VFIs protect critical infrastructure such as motors, production lines, and other machinery. Their reliable operation ensures minimal disruption in production processes.

Sustainability and Environmental Benefits

By avoiding the use of harmful gases like SF6, VFIs align well with environmental sustainability initiatives. Their long service life and low maintenance further reduce the environmental footprint of electrical systems.

For a more detailed understanding of VFIs, their functionalities, and their applications, you can visit this PowerGrid International article.

How Does an Interrupter Work?

Core Function of Interrupters

Interrupters are essential components in electrical systems used to disrupt the flow of current when a fault is detected or when the circuit needs to be opened or closed. They play a crucial role in ensuring the safety and reliability of electrical grids and installations.

Operating Mechanism

Detection and Response

The primary mechanism in interrupters revolves around the detection of fault conditions and the immediate response to them:

- Fault Detection: Various sensors and monitoring devices continually assess the current flowing through the circuit. If they detect abnormalities, such as overcurrent or short-circuit conditions, they send a signal to the interrupter.

- Activation: Upon receiving the fault signal, the interrupter’s actuating mechanism moves to separate the electrical contacts. The speed and efficiency of this action are critical in minimizing damage to the system components and ensuring safety.

Arc Extinguishing

When electrical contacts are separated to interrupt the current flow, an arc can form between them, which must be quenched. Different interrupter types use various methods to extinguish the arc:

| Interrupter Type | Arc Quenching Method |

|---|---|

| Air Circuit Breaker | Uses air as the arc quenching medium. |

| Oil Circuit Breaker | Immerses contacts in oil to extinguish the arc. |

| SF6 Circuit Breaker | Uses sulfur hexafluoride gas to quench the arc. |

| Vacuum Interrupter | Utilizes a vacuum environment to extinguish the arc. |

Benefits of Different Interruption Methods

Each arc extinguishing method offers unique advantages:

Air Circuit Breakers

- Durable: Suitable for low voltage applications and rugged environments.

- Simple Design: Relatively simple construction, which makes them easy to maintain.

Oil Circuit Breakers

- Heat Dissipation: Oil helps in cooling the arc and dissipating heat.

- Insulation: Provides high dielectric strength for effective arc quenching.

SF6 Circuit Breakers

- High Insulating Properties: Sulfur hexafluoride (SF6) gas has excellent insulating properties, making it effective at high voltages.

- Energy Efficient: Requires less energy to interrupt the current.

Vacuum Interrupters

- Environmentally Friendly: Avoids the use of harmful gases and oils.

- High Efficiency: Effectively quiches the arc quickly and reliably.

- Low Maintenance: Minimal moving parts reduce the need for frequent maintenance.

Advanced Features in Modern Interrupters

Innovations in modern interrupters have introduced several advanced features:

Remote Monitoring and Control

Remote technology allows operators to monitor interrupters from a distance, offering real-time data on system conditions and enabling prompt responses to faults.

Self-Diagnosis Systems

Integrated self-diagnostic tools can predict failures before they occur, improving reliability and reducing downtime.

Integration with Smart Grids

Smart grid compatibility means that interrupters can communicate with other grid components, optimizing the overall efficiency and responsiveness of the electrical network.

For further insights into how interrupters function and their application in different settings, you can explore detailed articles on Electrical Technology.

Understanding Vacuum Interrupters and Their Implications

Vacuum interrupters, VFIs, and other varieties of interrupters play a pivotal role in electrical systems. These devices, high in reliability and designed for optimal performance, offer a robust defense against power surges, short circuits, and other electrical anomalies. Both vacuum interrupters and VFIs utilize an internally generated vacuum for efficient and effective arc quenching, thus setting these types of interrupters apart from those that rely on air, oil, or SF6 gas.

These interrupters prove their worth in high voltage and high-frequency settings, balancing the environmental sustainability of the vacuum with robust performance. Furthermore, advances in fault detection, safety mechanisms, and self-diagnostic developments present new dimensions of operation in modern vacuum interrupters and VFIs. With applications spanning across utility networks, industrial settings, and other electrical systems, they play a pivotal role in reducing interruptions and ensuring stability in power systems.

Frequently Asked Questions – FAQs

What is the primary function of vacuum interrupters and fault interrupters?

Their primary role is to interrupt the flow of electric current, either when a fault is detected or during normal operations, like load switching.

What is the significance of the vacuum in these interrupters?

The vacuum within the interrupters acts as an effective medium for arc extinguishing, thus preventing the potential damage that arc could inflict on the system.

What sets a Vacuum Fault Interrupter (VFI) apart?

VFI’s can offer both short-circuit protection and load switching capabilities, making it versatile and efficient in fault management.

Are vacuum interrupters eco-friendly?

Yes. As vacuum interrupters don’t use oil or gas for quenching the arc, they present fewer risks to the environment.

Are vacuum interrupters used in high voltage applications?

Indeed, vacuum interrupters are used in high voltage circuit breakers, contributing to the reduction of potential environmental impact by minimizing the use of SF6 gas.