Intro To Raked Joints

Brickwork is an essential element of many buildings.

Did you know that small details like the way bricks are joined can significantly impact both a wall’s look and strength? One such concept is a ‘raked joint’.

But what exactly is a raked joint?

In this article, we will be exploring the specifics of raked joints. We will discuss the definition, characteristics, pros, and cons, plus where and when to use them. We’ll also examine the role they play in the maintenance of both residential and commercial buildings.

The aim is to enlighten you about the significance of raked joints, how to rake them out, and finally, we will compare raked joints with flush joints.

So, if you’re keen to learn about the role of joints in masonry, read on!

Table of Contents

Understanding the Construction Term: What is a Raked Joint?

Definition of a Raked Joint

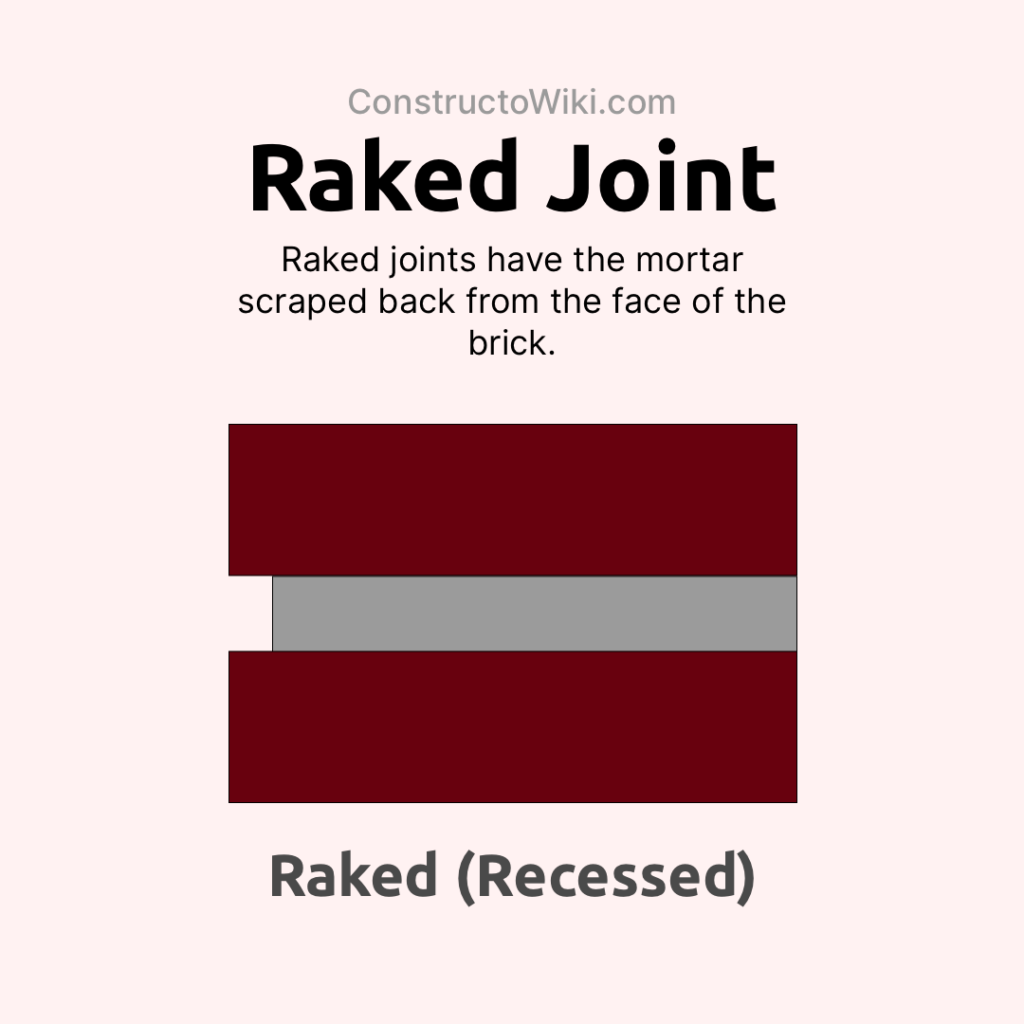

A raked joint is a type of mortar joint used in masonry. The mortar is recessed to create depth, highlighting the brickwork pattern.

Characteristics of Raked Joints

- Depth: The mortar is recessed typically by 1/4 inch to 1/2 inch from the face of the bricks.

- Appearance: Creates crisp shadows and a clear distinction between the bricks.

- Application: Mostly used in brick walls and facades to enhance visual appeal.

- Tooling: Achieved using a raking tool or chisel.

Pros and Cons of Raked Joints

| Pros | Cons |

|---|---|

| Enhanced visual design | Can expose the mortar joint to weather |

| Makes brick colors stand out | Requires more precision and skill |

When and Where to Use Raked Joints

Residential Buildings

- Brick facades on homes

- Fireplace surrounds

Commercial Buildings

- Storefronts with brickwork

- Exterior office walls

Maintenance Tips for Raked Joints

- Regular Inspection: Check for mortar erosion and refill as needed.

- Weatherproofing: Apply a sealant to protect against water penetration.

- Cleaning: Use mild cleaning agents and soft brushes to remove dirt without damaging the joints.

For more comprehensive details, you can refer to this useful guide on mortar joints that provides in-depth insights into various types of mortar joints used in construction.

The Importance of Raking Joints in Masonry

The Role of Raking Joints in Structural Integrity

While the aesthetic appeal of raked joints is undeniable, an overlooked element is the significant role raked joints play in the structural integrity of a masonry piece. When done correctly, raking creates more friction and adhesion between the brick and mortar, which can increase the overall strength of the structure. Yet, it’s a delicate balance. Too deep a rake can expose the joint to potential weather damage and weaken the structure, as mentioned earlier.

Raking for Mortar Replacement

Periodically, a masonry structure might need a refurbishment in the form of a repointing process. Repointing is the renewing of the mortar joints in brickwork. Before repointing, the existing, usually damaged, mortar must be removed to a certain depth. This is where raking comes in. Raking is a technique used to remove the old mortar. Thus, raking prepares the brick structure for the refreshing mortar.

The Practicality of Raking Joints

While the process requires skill and precision, raked joints do offer practical benefits. The recessed mortar provides a clear separation between bricks which assists professionals and DIY enthusiasts alike in visualizing the process of wall construction or repair. It delivers a mental map of the work as the project progresses.

Loss of Insulation and the Need for Raked Joints

Over time, bricks and mortar can wear, leading to a loss of insulation in a structure. Raked joints can play an essential part in restoring some of that lost insulation. When old, weather-worn mortar is raked out and replaced, the newly-filled joints provide better thermal resistance, helping keep buildings warm in winter and cool in summer.

Limitations of Raked Joints on Different Brick Types

Faced Bricks

- Raked joints tend to highlight any irregularities in the brick size or colour, making them unideal for faced bricks which often exhibit such variations.

Soft Bricks

- The process of raking can sometimes damage softer bricks. Hence, caution is advised while applying this technique on such materials.

For additional information on different mortar joint types and their impact on brickwork, visit this comprehensive guide on Architecture Lab.

How to Rake Out a Mortar Joint

Raking out a mortar joint involves removing the old or damaged mortar to a specified depth to make way for fresh mortar. The process is essential for repointing work, ensuring that the new mortar adheres well and maintains the structural integrity and appearance of the brickwork.

Tools Required for Raking Out a Joint

Effective raking involves using the right tools. Here’s a list of tools you’ll need:

- Raking Tool: A specialized tool used to remove the mortar cleanly from the joint.

- Hammer and Chisel: For deeper or more stubborn mortar, a hammer and chisel can help break it out.

- Angle Grinder: For large-scale projects, an angle grinder with a mortar rake attachment can expedite the process.

- Brush: A stiff brush to clean out the debris from the joints.

- Safety Gear: Goggles, gloves, and a dust mask are essential to protect yourself from debris and dust.

Step-by-Step Process

Here are the steps to rake out a joint:

Step 1: Safety First

Before starting, put on your safety goggles, gloves, and a dust mask to protect yourself from debris.

Step 2: Choose the Right Tool

Depending on the scale and condition of your project, select either a manual raking tool, a hammer and chisel, or an angle grinder. Manual tools are suitable for smaller, more delicate work, while an angle grinder is better for larger, tougher tasks.

Step 3: Rake the Joint

Start by placing the raking tool at the joint and applying steady pressure to remove the mortar. If using an angle grinder, ensure it’s set at the correct depth (typically 1/4 to 1/2 inch) to avoid damaging the bricks.

Step 4: Clean the Joints

Once the mortar is removed, use a stiff brush to clean out any remaining debris. This step ensures that the new mortar adheres correctly and looks neat.

Step 5: Inspect Your Work

Check the joints to ensure that all the damaged or old mortar has been adequately removed. The depth should be consistent to create a solid bed for the new mortar.

Considerations and Best Practices

- Consistency: Aim for consistent depth across all joints to avoid weak spots.

- Avoid Over-Raking: Removing too much mortar can weaken the structure. Stick to the recommended depth.

- Weather Conditions: Avoid raking and repointing in extreme weather. Cold or rainy conditions can affect the new mortar’s setting process.

- Brick Type: Consider the type of brick you’re working with. Some bricks, especially softer ones, can be more prone to damage during the raking process. Apply more caution if necessary.

What is the Difference Between Raked and Flush Mortar?

Definition of Flush Mortar Joint

A flush mortar joint differs significantly from a raked joint. In a flush joint, the mortar is applied level with the brick face, filling the joint completely. This creates a smooth and streamlined appearance without recesses.

Characteristics of Flush Mortar Joints

- Depth: The mortar is level with the brick face, leaving no recess.

- Appearance: Creates a seamless look, often blending the bricks and mortar together.

- Application: Commonly used in brick walls and structures where a clean and uniform look is desired.

- Tooling: Achieved using a trowel or jointing tool to smooth the mortar flush with the brick face.

Pros and Cons of Flush Mortar Joints

| Pros | Cons |

|---|---|

| Less prone to water penetration | Less pronounced brick pattern |

| Requires less maintenance | Can show cracks more visibly over time |

| Provides a uniform surface | Less visual interest compared to raked joints |

When and Where to Use Flush Joints

Residential Buildings

- Homes with a modern aesthetic

- Interior walls where a smooth finish is preferred

Commercial Buildings

- Facade renovations aiming for a sleek appearance

- Public buildings requiring durable and uniform surfaces

Maintenance Tips for Flush Joints

- Regular Cleaning: Use mild cleaning solutions to maintain the uniform look.

- Inspection: Periodically check for cracks and signs of wear.

- Repair: Address any damage promptly to maintain the integrity of the structure.

Differences in Application and Aesthetics

Visual Appeal

Raked joints emphasize the individual bricks by creating shadows and depth, making them ideal for projects where the visual complexity of the brickwork is a desired feature. Flush joints, on the other hand, create a smoother, more homogeneous look that minimizes the visibility of individual bricks.

Durability and Weather Resistance

Flush mortar joints offer better resistance to water penetration since the mortar fills the joint completely and makes it less susceptible to erosion. This makes flush joints particularly effective in regions that experience heavy rainfall or freeze-thaw cycles. Raked joints, while aesthetically pleasing, can expose the edges of the bricks to the elements more readily.

Choosing Between Raked and Flush Joints

Project Goals

- Architectural Style: Raked joints are better for traditional or rustic designs, while flush joints suit modern or minimalistic styles.

- Climate Considerations: For areas prone to heavy rains or snow, flush joints may offer better durability.

- Skill Level: Flush joints are generally easier for less experienced masonry workers, while raked joints require more precision.

Material Compatibility

- Brick Type: Softer bricks may be better suited to flush joints to prevent damage during raking.

- Mortar Type: The choice of mortar can also influence the suitability of each joint type, especially concerning weather resistance and bonding strength.

Final Thoughts on Raked Joints in Masonry

In conclusion, raked joints are an integral component in masonry, mainly emphasizing the aesthetic elements of brickwork, while also aiding the structural integrity. However, their application requires precision and skill, considering factors such as the depth of the mortar recess and the type of brick used.

They are suitable for both residential and commercial buildings, especially where the distinctiveness of the brick pattern is desired. Maintenance of raked joints involves regular inspection for mortar erosion, weatherproofing, and careful cleaning.

Raked joints play a significant role, not only in beautification but also in structural restoration, thermal insulation enhancement, and even in refurbishments during the repointing process. While they showcase the brickwork elegantly, they also underline potential brick irregularities, especially in faced and soft bricks.

Therefore, the choice between raked and flush joints in a project comes down to the architectural style, climate, individual skill level, and the type of materials used in construction.

Frequently Asked Questions – FAQs

What are raked joints in masonry?

A raked joint is a type of mortar joint in which the mortar is recessed, highlighting the brickwork pattern. This recess is typically 1/4 inch to 1/2 inch deep from the face of the bricks.

Why are raked joints important?

Raked joints improve the aesthetic appeal of brickwork by creating crisp shadows and a clear distinction between bricks. Additionally, they can increase the overall strength of masonry structures and assist in visualising construction or repair processes.

When should I use raked joints?

Raked joints are mostly used in brick walls and facades where you want to enhance the visual appeal. They can be used in both residential buildings (like home facades and fireplace surrounds) and commercial buildings (like storefronts with brickwork and exterior office walls).

What are the limitations of raked joints?

Raked joints can expose the mortar joint to weather, requiring more maintenance than some other types of joints. They also require more precision and skill to create, and they could potentially damage soft bricks or highlight irregularities on faced bricks.

What is the difference between raked and flush joints?

The main difference lies in the depth and appearance of the mortar. In raked joints, the mortar is recessed to create depth. In contrast, in flush joints, the mortar is level with the brick face, creating a smooth look and minimizing the visibility of individual bricks.