What is Corner Reinforcement In Construction?

Did you know that poorly reinforced corners are among the most common causes of structural failures in buildings?

That’s right. Without proper reinforcement, corners can easily crack and lose stability.

In this article, we’ll take a close look at what corner reinforcement is and why it’s so essential in construction.

We’ll explore its importance, various types, and the benefits it provides.

Armed with this knowledge, you’ll understand how to ensure your structures remain stable and long-lasting.

Table of Contents

Understanding Construction Terms: Corner Reinforcement

Introduction to Corner Reinforcement

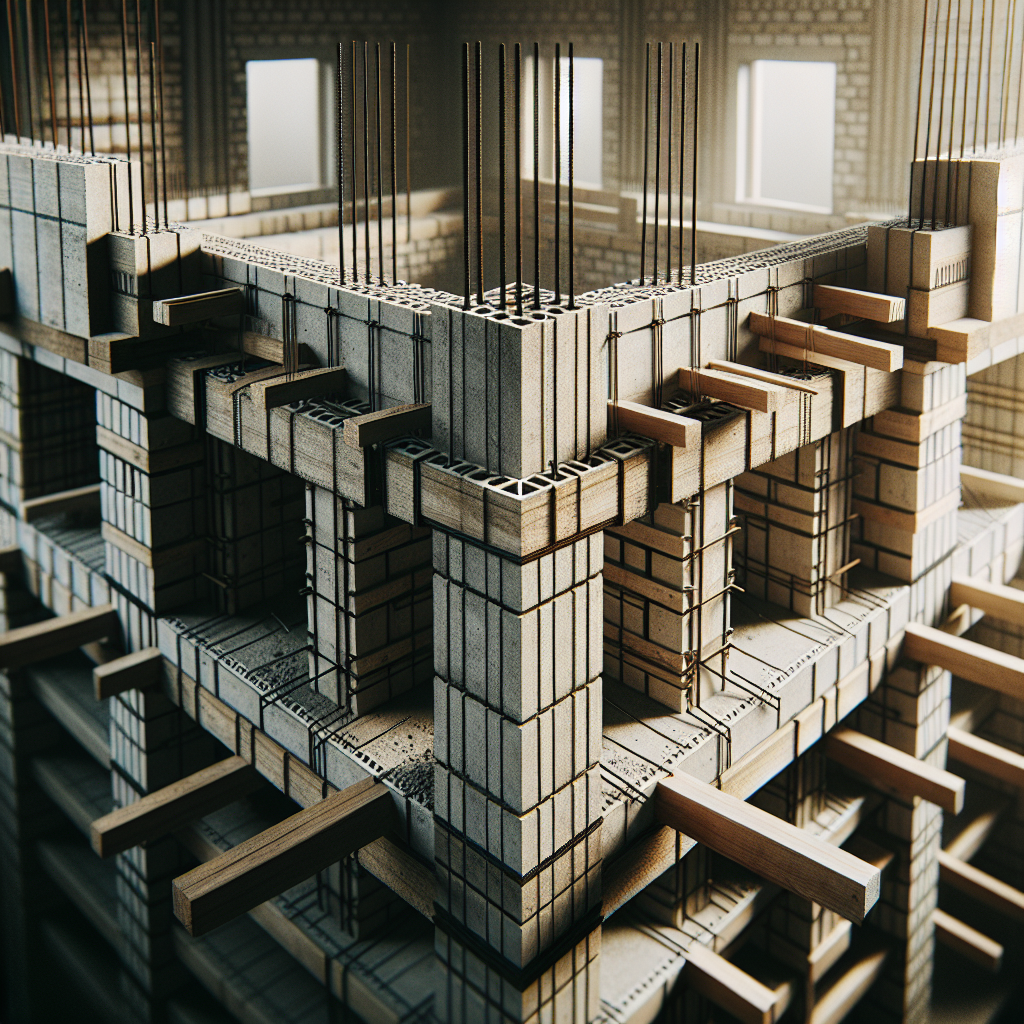

Corner reinforcement is a key aspect of construction, particularly in masonry and concrete work. It involves strengthening the corners of a structure to prevent cracking, ensure stability, and extend the lifespan of the building.

Importance of Corner Reinforcement

Corners are typically the most vulnerable parts of a structure due to stress concentrations. Proper corner reinforcement:

- Prevents cracks in the corners.

- Enhances structural stability.

- Reduces maintenance costs over the building’s lifetime.

Types of Corner Reinforcement

Concrete Corner Reinforcement

In concrete construction, corner reinforcement is achieved using specific engineering techniques. Key methods include:

- Using additional rebar (reinforcing bars) in the corner areas.

- Applying reinforcing meshes.

- Incorporating steel angles or plates.

Masonry Corner Reinforcement

In masonry work, corner reinforcement involves using various techniques such as:

- Inserting metal ties or mesh at the corners.

- Positioning additional brick or block units in a staggered manner.

- Applying structural adhesives or bonding agents.

Benefits of Corner Reinforcement

| Benefit | Description |

|---|---|

| Durability | Extends the life of the structure by minimizing damage from stresses and cracks. |

| Safety | Ensures the building remains safe and sound by maintaining its integrity. |

| Cost-Effective | Reduces the need for costly repairs and maintenance over time. |

Real-World Application

In real-world scenarios, corner reinforcement is used in various construction projects such as:

- Residential buildings

- Commercial properties

- Infrastructure projects like bridges and tunnels

For more detailed guidance on construction practices, check resources like Concrete Network for comprehensive information.

Always consult with a construction engineer to choose the right type of corner reinforcement for your specific project.

Why Corner Reinforcement is Important in Masonry Construction

Impact on Structural Integrity

Masonry structures, including buildings and load-bearing walls, are subject to various external and internal forces. Without proper corner reinforcement, these structures can become susceptible to severe damage. Here’s why it’s critical:

- Stress Distribution: Corners experience concentrated stresses, which can lead to cracking and failure. Reinforcement helps distribute these stresses more evenly.

- Wind and Seismic Forces: Buildings face lateral forces from wind and seismic activities. Reinforced corners better absorb and withstand these forces, preventing structural collapse.

Methods of Masonry Corner Reinforcement

Rebar Addition

The addition of reinforcing bars (rebars) is one of the most effective ways to strengthen masonry corners. This method involves inserting rebar into the masonry units before pouring mortar, providing additional tensile strength.

Use of Lintels and Bond Beams

Lintels and bond beams incorporate horizontal reinforcements that link the masonry units, offering added stability. They are essential for areas subject to dynamic loads, such as door and window openings near corners.

Grouted Cells

Grouting the hollow cells of masonry units with concrete provides additional solidity to the corners. This technique makes the structure more cohesive and less prone to cracking.

Building Codes and Standards

Adhering to building codes and standards is critical for ensuring structural safety. Most building codes have specific requirements for corner reinforcement in masonry construction:

| Code/Standard | Requirement |

|---|---|

| ACI 530/ASCE 5/TMS 402 | Specifies minimum reinforcement amounts and placement for masonry structures. |

| IBC (International Building Code) | Includes guidelines for reinforcement in various construction types, including masonry. |

| Local Building Codes | May have additional requirements specific to geographic hazards like earthquakes and high winds. |

Innovations in Corner Reinforcement

Innovative materials and technologies are continually being developed to enhance the effectiveness of corner reinforcement. Here are a few cutting-edge options:

- Fiber-Reinforced Polymers (FRP): These materials offer high tensile strength and corrosion resistance, making them ideal for reinforcing masonry corners.

- Self-Healing Concrete: This technology uses bacteria embedded within the concrete to heal cracks automatically, significantly reducing the need for maintenance.

- 3D Printing: Advances in 3D printing allow for the creation of complex reinforcement shapes tailored to specific stress patterns in corners.

For further insights into the latest techniques and materials, check out resources such as Concrete Network, which offers a wealth of information on innovative construction practices.

Ensuring that your masonry structures are well-reinforced at the corners is paramount for long-term durability and safety. Always seek professional advice to select the most appropriate reinforcement method for your specific needs.

Types of Reinforcement in Masonry Construction

Reinforcement Techniques in Masonry Construction

Adding reinforcement to masonry construction is critical to improve the strength and durability of the structure. There are several methods to reinforce masonry walls depending on the specific requirements and conditions of the building. Here’s an overview:

Vertical Reinforcement

Vertical reinforcement involves inserting steel reinforcing bars (rebar) vertically into the masonry walls, typically within grouted cells. This method increases the vertical load-bearing capacity of the walls and enhances their stability against lateral forces such as wind and earthquakes.

- Standard Rebar: Commonly used in residential and commercial masonry construction.

- Post-Tensioned Rebar: Used in situations requiring high tensile strength and minimal deformation.

Horizontal Reinforcement

Horizontal reinforcement includes placing steel bars or wire mesh horizontally within the mortar joints. This technique is essential for distributing loads uniformly and reducing the risk of cracking.

- Ladder Reinforcement: Consists of parallel steel wires welded to cross wires, placed in the mortar bed layers of masonry walls.

- Truss Reinforcement: A triangulated wire design that provides additional resistance to shear forces.

Grouting and Bond Beams

Grouting involves filling the hollow cores of masonry units with concrete, which increases the material’s compressive strength. Bond beams are horizontal reinforcements integrated into the masonry structure to provide additional support.

- Standard Grouting: Used to fill the voids in concrete masonry units (CMUs) to strengthen the entire structure.

- Bond Beams: Placed at specific intervals along the height of the wall, especially above door and window openings, to add rigidity and reduce stress concentrations.

Reinforcement Materials

Steel Reinforcement

Steel is the most common material used for masonry reinforcement due to its high tensile and compressive strength.

- Standard Steel Rebar: Widely used and available in various grades and sizes.

- Galvanized Steel: Provides improved resistance to corrosion, making it suitable for structures exposed to moisture.

Fiber Reinforcement

Fiber reinforcement, including fiber-reinforced polymers (FRPs), is becoming popular due to its lightweight and high tensile strength.

- Carbon Fiber Reinforcement: Offers superior strength and stiffness with minimal weight.

- Glass Fiber Reinforcement: Provides excellent tensile strength and resistance to corrosion.

Composite Materials

Composite materials combine different substances to optimize the properties required for structural reinforcement.

- Glass Fiber-Reinforced Polymer (GFRP): Balances affordability and performance, commonly used in various applications.

- Carbon Fiber-Reinforced Polymer (CFRP): Offers exceptional performance for high-load applications but can be costlier.

Common Applications of Reinforcement in Masonry

Reinforcement techniques are applied in several essential parts of masonry structures to enhance their performance:

- Load-Bearing Walls: To support vertical loads and improve resistance to lateral forces.

- Shear Walls: Designed to resist horizontal forces and prevent structural failure during seismic events.

- Retaining Walls: To withstand the lateral pressure from soil and prevent displacement.

For more information on the latest methods and materials for masonry reinforcement, consult resources such as Concrete Network.

What is Corner Bar in Masonry Construction?

Introduction to Corner Bars

In masonry construction, corner bars, also known as corner reinforcement bars, play a vital role in the structural integrity of masonry units. These bars are specifically designed to reinforce and stabilize the corners of a masonry structure, providing additional strength in areas that are prone to stress and cracking.

Purpose of Corner Bars

Corner bars are implemented in masonry construction to achieve various critical objectives:

- Improve Structural Stability: They provide additional support to the corners of masonry walls, helping to maintain the shape and stability of the structure.

- Prevent Cracks: By reinforcing the corners, these bars help to mitigate the development of cracks due to stress concentration.

- Enhance Load-Bearing Capacity: Corner bars increase the load-bearing capacity of the structure, ensuring it can support additional weight and stress without deteriorating.

Types of Corner Bars in Masonry

Standard Steel Corner Bars

Standard steel corner bars are commonly used due to their high tensile strength and durability. They are typically made of reinforced steel and are available in various sizes to suit different construction needs.

- Dimensions: Standard steel corner bars come in different diameters and lengths, tailored for specific applications within the masonry structure.

- Installation: These bars are usually embedded within the mortar joints or inserted into pre-drilled holes in the masonry units and then grouted for stability.

Galvanized Steel Corner Bars

Galvanized steel corner bars are coated with zinc to prevent corrosion, making them suitable for structures exposed to moisture or corrosive environments.

- Corrosion Resistance: The galvanization process helps protect the steel from rust and environmental damage, extending the lifespan of the masonry structure.

- Applications: Commonly used in coastal areas, industrial buildings, and structures exposed to harsh weather conditions.

Fiber-Reinforced Polymer (FRP) Corner Bars

Fiber-reinforced polymer corner bars are made from composite materials that offer high tensile strength and flexibility while being lightweight.

- Lightweight and Strong: These bars provide significant reinforcement without adding excessive weight to the structure, making them ideal for high-stress applications.

- Corrosion Resistance: FRP materials are resistant to corrosion, making them suitable for use in various environments, including marine and chemical industries.

Installation Techniques for Corner Bars

Embedding in Mortar Joints

One method involves embedding the corner bars directly into the mortar joints between masonry units.

- Method: The bars are placed in the corner areas during the construction process before the mortar sets, ensuring they are well anchored.

- Benefits: This technique ensures that the reinforcement is integral to the structure, providing consistent support and stability.

Grouting in Pre-Drilled Holes

Another method is inserting the corner bars into pre-drilled holes in the masonry units and then filling the holes with grout.

- Method: Holes are drilled at the corners of the masonry units, the bars are inserted, and then grout is poured to secure them in place.

- Benefits: Ensures a strong bond between the corner bars and the masonry units, enhancing the overall integrity of the structure.

Regulations and Best Practices

Adhering to building codes and standards is crucial when incorporating corner bars in masonry construction. These guidelines ensure that the reinforcement meets the necessary safety and performance requirements.

| Code/Standard | Requirement |

|---|---|

| ACI 530/ASCE 5/TMS 402 | Specifies minimum reinforcement requirements and placement for masonry structures. |

| IBC (International Building Code) | Provides guidelines on the use of reinforcement in various construction types, including masonry. |

| Local Building Codes | May have additional requirements, especially in areas prone to specific environmental hazards. |

For more detailed information on the use of corner bars in masonry construction, consult reliable sources like the Concrete Network. Always involve a professional engineer to determine the most appropriate reinforcement strategy for your specific project.

Conclusion On Corner Reinforcement

Corner reinforcement plays a vital role in the structural integrity of masonry and concrete construction.

By effectively dispersing stress, preventing cracks, and enhancing durability, different methods of corner reinforcement, from steel rebar to innovative materials like fiber-reinforced polymers, ensure long-lasting and stable structures.

Don’t overlook this critical component—consult a construction engineer to select the best reinforcement method for your project.

Frequently Asked Questions – FAQs

What is corner reinforcement?

Corner reinforcement involves strengthening the corners of a structure to prevent cracking and ensure stability. This is particularly important in masonry and concrete work.

Why are corners vulnerable in construction?

Corners experience concentrated stresses, which make them more susceptible to cracking. Proper reinforcement helps distribute these stresses evenly.

What are some common methods of corner reinforcement in concrete construction?

Common methods include using additional rebar, applying reinforcing meshes, and incorporating steel angles or plates.

How is corner reinforcement achieved in masonry work?

Techniques include inserting metal ties or mesh at the corners, positioning additional bricks in a staggered manner, and applying structural adhesives or bonding agents.

What are the benefits of corner reinforcement?

It extends the structure’s lifespan, enhances safety by maintaining structural integrity, and reduces long-term maintenance costs.

What innovative materials are used in corner reinforcement?

Novel materials include fiber-reinforced polymers, self-healing concrete, and advanced 3D printing techniques for tailored reinforcement shapes.