A Brief Insight into the World of Retrofitting

What does retrofitting old structures with reinforced concrete entail?

It’s a method commonly employed within the construction industry, aimed at enhancing the durability and safety of an existing structure. This is done by integrating reinforcing elements into the original framework.

Let’s take a deeper look.

Table of Contents

Retrofitting Old Structures with Reinforced Concrete

In the construction industry, the concept of retrofitting old structures with reinforced concrete is fairly common.

But what exactly does this mean?

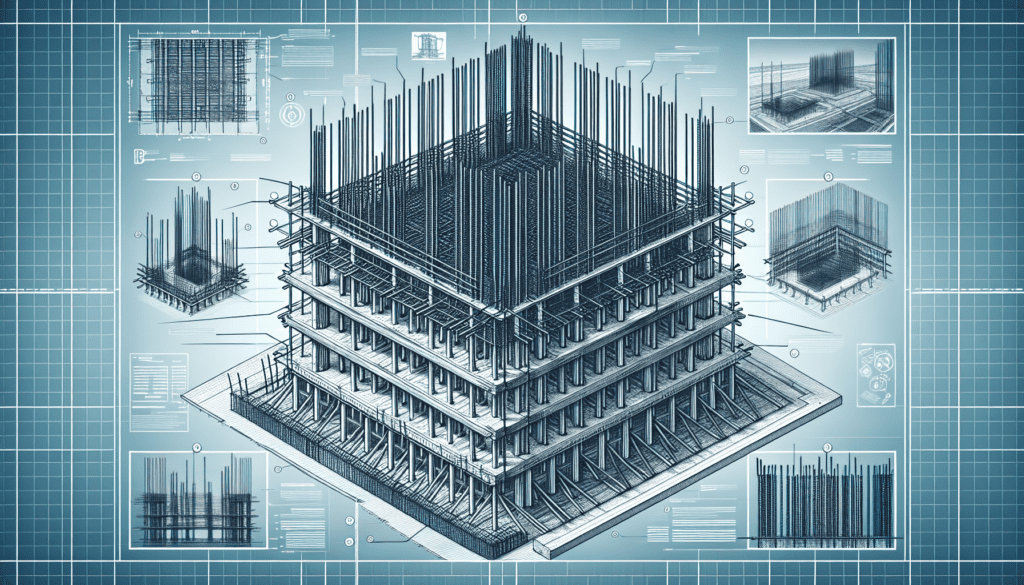

In essence, it refers to the process of enhancing the structural integrity of an existing building by incorporating reinforcement elements into the original framework.

What Does Retrofitting Mean?

Retrofitting, from a structural perspective, means upgrading an existing building or facility’s structure to withstand specific conditions such as seismic activities, to adhere to modern safety standards, or to enhance its durability and function.

Why Use Reinforced Concrete?

Reinforced concrete, a composite material that consists of concrete and steel rebars, provides exceptional strength and ductile behavior under load conditions. This makes it an ideal material for structural enhancement.

Process of Retrofitting Old Structures with Reinforced Concrete

The process of retrofitting old structures involves several key steps outlined below:

- Evaluation of Existing Structure

- Determination of Retrofitting Needs

- Development of Retrofitting Plan

- Implementation of Retrofitting Plan

- Final Inspection and Approval

Evaluation of Existing Structure

Before moving forward with the retrofitting process, an in-depth evaluation of the existing structure is carried out. The evaluation helps determine the structure’s weaknesses and strengths alike that will influence the retrofitting method to be used.

Determination of Retrofitting Needs

After a thorough evaluation, the need for retrofitting is identified. Case in point, should the building show signs of vulnerability to seismic activities, the upgrade will focus on enhancing the structural integrity to withstand such stresses.

Development of Retrofitting Plan

A comprehensive retrofitting plan is developed, taking into consideration the existing structure’s conditions, the budget, and the desired outcomes.

Considerations in Retrofitting Old Structures with Reinforced Concrete

Retrofitting an old structure with reinforced concrete involves plenty of factors that constructors must bear in mind.

Structural Assessment

A critical initial step is to properly assess the structural merit of the existing building. This requires knowledge and expertise from structural engineers.

Regulatory Compliance

Each jurisdiction has specific building codes and regulations. It is essential that any retrofitting works meet these legal requirements.

Cost

The cost of materials, labor, and other expenses related to the retrofitting process should also be considered, ensuring the project’s feasibility and practicality.

Bottom Line

Yes, old structures can indeed be retrofitted with reinforced concrete. This involves a detailed process that includes structural evaluation, designing a retrofitting plan, and execution with due consideration for regulatory, financial, and practical constraints.

Acknowledging this, the decision to retrofit must be carefully considered, ensuring it meets the needs and demands of the structure at present and in the future.

Key Factors in Deciding on Using Reinforced Concrete in Construction

What factors should be considered when deciding to use reinforced concrete? Let’s break them down.

1. Durability and Strength

One of the main reasons to choose reinforced concrete is its strength and durability.

Advantages of Reinforced Concrete

- Resistant to fire and water: Concrete has the ability to withstand fire and water, making it an excellent choice for buildings in locations prone to either of these elements.

- Withstands high pressure: With its steel reinforcement, concrete can handle high pressure, which is critical in the construction of high-rise buildings and heavy-duty infrastructure.

2. Cost-Effectiveness

Economic considerations are a key aspect when choosing building materials.

The Economic aspect of Reinforced Concrete

- Maintenance: Reinforced concrete requires less maintenance, reducing the long-term cost.

- Long-lasting: Despite the initial high cost, the long lifespan of reinforced concrete can make it more cost-effective in the long run.

3. Flexibility in Design

Reinforced concrete is favored by architects for its design flexibility.

Design Versatility of Reinforced Concrete

- Adaptability: Concrete can be poured into molds to take on any shape, allowing for creative and functional designs.

- Color and texture: Concrete’s color and texture can be manipulated, contributing significantly to the aesthetics of a design.

It is crucial, however, that while considering these advantages, one should also consider the environmental impact and sustainability of using the material.

According to the ScienceDirect, concrete production can contribute significantly to CO2 emissions. Therefore, it’s crucial to choose suppliers that use environmentally friendly manufacturing processes.

| Consideration | Advantages |

|---|---|

| Durability and Strength | Resistant to fire and water, can withstand high pressure |

| Cost-Effectiveness | Affordable maintenance, long lifespan |

| Flexibility in design | Adaptable, variable color and texture |

Remember these points the next time you’re deciding whether or not to use reinforced concrete for your construction project. It’s a flexible, strong, and cost-effective material that, when used responsibly, can contribute to sustainable construction practices.

Preparing and Installing Reinforced Concrete

Preparation of Reinforced Concrete

1. Designing the structure

The first step in the process is drafting a design for the intended structure. This blueprint determines factors like the size and placement of the reinforced steel bars.

2. Constructing the formwork

Formwork serves as the “mold” that shapes and holds the concrete during the curing process. It can be made of materials like plywood, steel, or plastic, depending on the projected outcome.

3. Positioning the reinforcement

Once the formwork is in place, steel bars are strategically placed inside to give the final product its strength. Steel bar placement has to be done with a significant amount of precision, as it significantly impacts the concrete’s final strength and stability.

Installation of Reinforced Concrete

1. Mixing and pouring the concrete

After setting the steel bars up, the concrete mix—composed of cement, aggregates, water, and sometimes additives—is prepared. This mix is then poured into the formwork containing the steel reinforcement. Adequate steps should be taken to avoid the segregation of mix components.

2. Curing

This is the crucial stage where the wet concrete hardens and gains its strength. It is achieved by maintaining the moisture content within the concrete. This process normally takes place over a period of one to two weeks.

3. Formwork removal

Once the concrete has cured and hardened, the molds (formwork) are carefully removed, unveiling the finished reinforced concrete structure.

By understanding these steps, you can better appreciate the process of preparing and installing reinforced concrete—a resilient, versatile material that forms the backbone of many structures around us.

Wrapping It Up On Reinforced Concrete

In our exploration of retrofitting old structures with reinforced concrete, we’ve found that it’s a complex process requiring careful evaluation, planning, and execution. However, the potential benefits of enhanced structural integrity and meeting modern safety standards make it a worthwhile pursuit.

Retrofitting, when properly implemented, can breathe new life into old structures, ensuring their durability and functionality for years to come.

The transformative potential of retrofitting lies not just in its practical, physical outcomes, but also in what it represents – a commitment to preservation and sustainable development.

From our perspective, it is inherently about striking a balance between honoring the past and embracing the necessity for change.

Perhaps the most important takeaway we’ve drawn from this comprehensive guide is that each retrofitting project is uniquely dependent on the specific conditions of the existing structure, with no one-size-fits-all solution. Therefore, a clear understanding of the structure’s conditions, careful budget planning, and adherence to local regulations are crucial to a successful retrofit.