Understanding Warping Joints in Construction

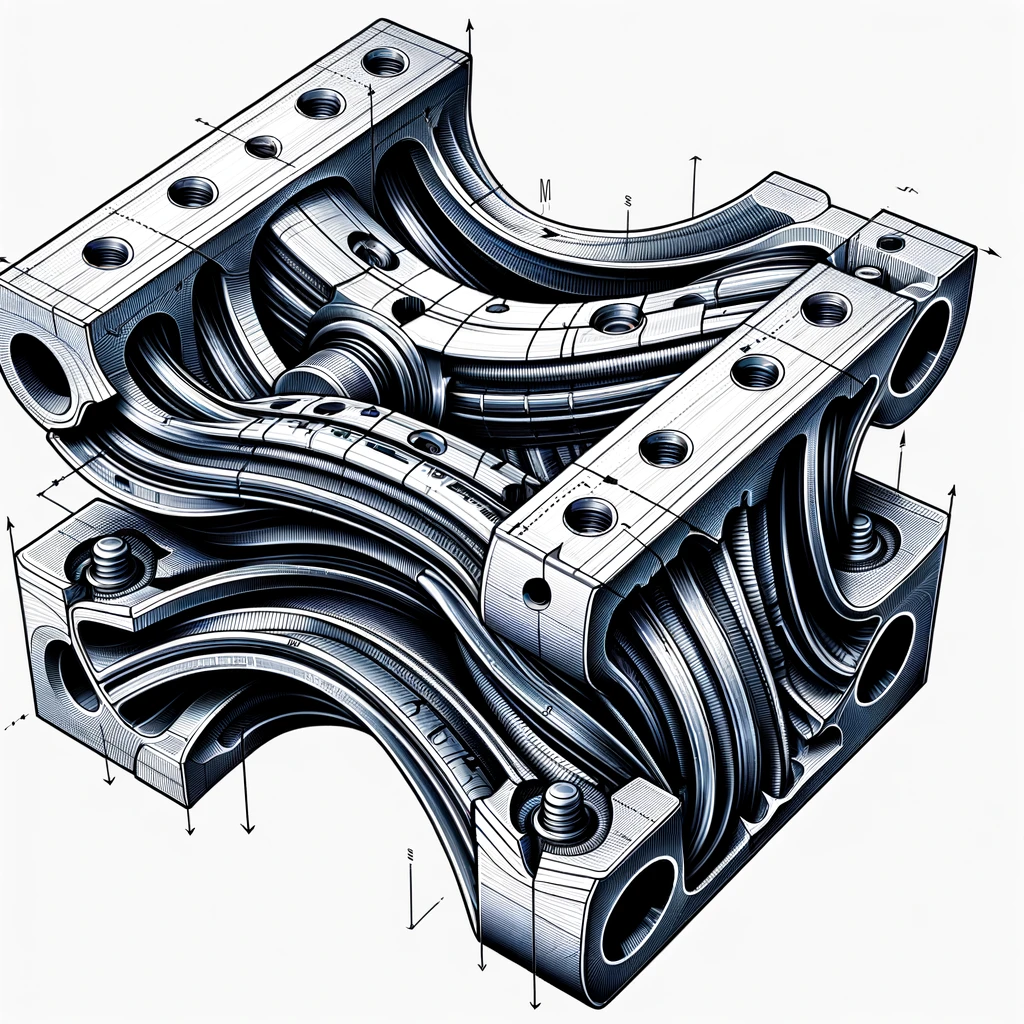

A “warping joint” is a purposely implemented feature in construction that accounts for natural shifts in structures due to changes in climate, substrate movements or curing.

They provide flexibility to a structure, reducing the risks linked with rigidity such as cracking or warping under environmental stress.

Within the field of construction, the utility of warping joints is paramount – integral to durability and subsequent longevity of the built object.

Table of Contents

Let’s Explore More: What is a Warping Joint?

Definition of a Warping Joint

A warping joint, in the simplest of terms, is a joint or connection that allows for warping or twisting without causing damage or structural impairment.

In other words, it’s designed to withstand and accommodate the natural shifts and movements that occur within a structure.

When is a Warping Joint Used?

A warping joint is commonly used in long, continuous construction objects such as pipelines, roads, railways and building frames that need to allow for changes due to temperature variations, humidity, or other environmental factors.

- Buildings: Often used in larger building frames, especially in skyscrapers or in buildings prone to high wind pressures.

- Pipelines: These joints are frequently found in long, linear pipeline systems that traverse through geographic areas with varying temperatures.

- Roadways and Railways: Similarly, these joints are integrated into long roadways or railway tracks to allow for safe expansion and contraction due to temperature changes.

Benefits of Using a Warping Joint

The use of a warping joint in construction projects offers a number of benefits:

- Flexibility: Enables structures to withstand changes without damage.

- Safety: Increases the overall safety of a structure by reducing risk of failure due to environmental changes.

- Longevity: Can potentially increase the lifespan of a structure by allowing for natural movement.

In conclusion, the warping joint plays an essential role in the construction industry, allowing structures to flex and move as needed while still maintaining their structural integrity.

Understanding lesser-known terms like this can equip construction professionals with the knowledge they need to create safer, more durable structures.

Digging Deeper: What is Warping Stress?

Now that we’ve examined what a warping joint is, it’s a good time to take a look at another related concept in the construction industry: warping stress.

An Overview of Warping Stress

In essence, warping stress refers to the strain that irregular bending forces can place on a structural object.

This stress is often the result of differences in temperature, material properties, or loading, which may cause parts of the structure to expand, contract, twist or distort in different ways.

Nature of Warping Stress

Warping stress can be tremendously damaging to a structure if it’s not adequately addressed.

For instance, it could lead to cracks, fractures, and even collapse in severe cases. It’s inherently complex because it can vary greatly depending on the material, dimensions of the structural parts, and the actual forces applied.

Relation of Warping Joint to Warping Stress

The warping joint and warping stress are closely intertwined concepts.

A warping joint has its role in the process of mitigating the adverse effects of warping stress. By allowing flexibility and movement in specific parts of a structure, a warping joint can aid in reducing the overall stress and protect the structure from potential damage.

Managing Warping Stress with Warping Joints

Deploying warping joints can help manage the effects of warping stress in the following ways:

- Distribution of Stress: These joints can help distribute the stress across a wider area, reducing the risk of concentrated stress points that can lead to structural damage.

- Limiting Distortion: By allowing controlled movement, warping joints can limit distortion and maintain the structure’s shape and orientation.

- Avoiding Material Damage: Proper use of warping joints can minimize damage to the material, thus preserving the overall structural integrity.

Wrapping It Up On Warping Stress

While they may be complex concepts, understanding warping joints and warping stress can provide key insights for any construction professional.

These terms underscore the importance of considering and accommodating structural movement and stress in the design and construction process, thereby ensuring the longevity and safety of the structures.

As the industry looks forward to advancements in technology and material science, the principles of handling warping stress and effective utilization of warping joints will remain paramount.

Exploring Contraction Joints in Construction

With an understanding of warping joints and warping stress, we can expand our horizon to another essential element utilized in construction – the contraction joint.

What is a Contraction Joint?

Contraction joints, also known as control joints, are deliberate gaps placed between concrete slabs to control where cracks, caused by concrete’s tendency to shrink as it dries and hardens, occur.

Essentially, they are pre-planned breaks in the continuity of the structure that allow for shrinkage movement, minimizing the risk of random cracking.

Significance of Contraction Joint

The purpose of a contraction joint is inherently different from a warping joint. While both entail designed flexibility, a contraction joint aims to manage the contraction of material, particularly concrete.

As concrete structures dry and harden, shrinkage occurs – typically in an unpredictable way. Contraction joints are the construction industry’s successful design response to this issue – they guide these cracks along a specified path, away from areas of structural concern.

When are Contraction Joints Used?

Contraction joints are most commonly implemented in long, linear construction structures where concrete shrinkage due to drying can cause aesthetic and structural damage.

These include but are not limited to:

- Roadways: Control joints are used in concrete roads to induce cracks at specific locations, preventing random and unsightly cracking.

- Pavements and Sidewalks: Sidewalks and pavements also utilize these joints to prevent cracks from forming at irregular places.

- Foundations: Many building foundations require contraction joints, particularly if the foundation uses larger expanses of concrete.

Types of Contraction Joints

There are different types of contraction joints, each with its own unique features and uses including hand-tooled joints, sawed joints, and formed joints.

The choice of the type of joint to use depends on several factors including the thickness of the concrete, the type of structure, and the expected shrinkage of the concrete.

Benefits of Using Contraction Joints

The inclusion of contraction joints in a construction project offers several advantages:

- Prevention of Random Cracking: By providing a predefined path, contraction joints prevent random cracking in the concrete caused due to shrinkage.

- Maintaining Aesthetic Appeal: In addition to structural benefits, they also maintain the visual appeal of the structure by preventing unsightly random cracks.

- Structural Preservation: They help preserve the structural integrity of the concrete by managing shrinkage effectively.

A Conclusion On Contraction & Warping Joints

To wrap up, both warping joints and contraction joints play a massive role in the construction industry, albeit serving different purposes.

While the former deals with flexibility and warping stress management, the latter focuses on managing shrinkage, preventing excessive and random cracking in concrete structures. Understanding these terms is pivotal for construction professionals aiming to create durable, safe, and aesthetic structures that can withstand the test of time and the elements.

In decoding the often complex language of construction terminology, we’ve found that a warping joint is standout. Not only does it provide functionality by enabling structures to withstand alterations without damage, but also improves safety and longevity of a construction project.

Crucially, these joints are used in a range of structures – buildings, pipelines, roadways, and railways – all benefiting from the inherent flexibility they offer.

From our perspective, the utilization of a warping joint bridges the gap between construction robustness and the unavoidable impact of environmental change.

From skyscrapers standing tall against high wind pressures to expansive roadways adapting to fluctuating temperatures, the benefits are clear. Hence, this knowledge is vital for every construction professional aiming to create resilient, lasting structures in an ever-changing world.