Air Blast Breakers: A Crucial Component in Construction

The term ‘Air Blast Breakers’ sounds complex to the untrained ear, but it’s simple when broken down. In the world of construction, this term is key.

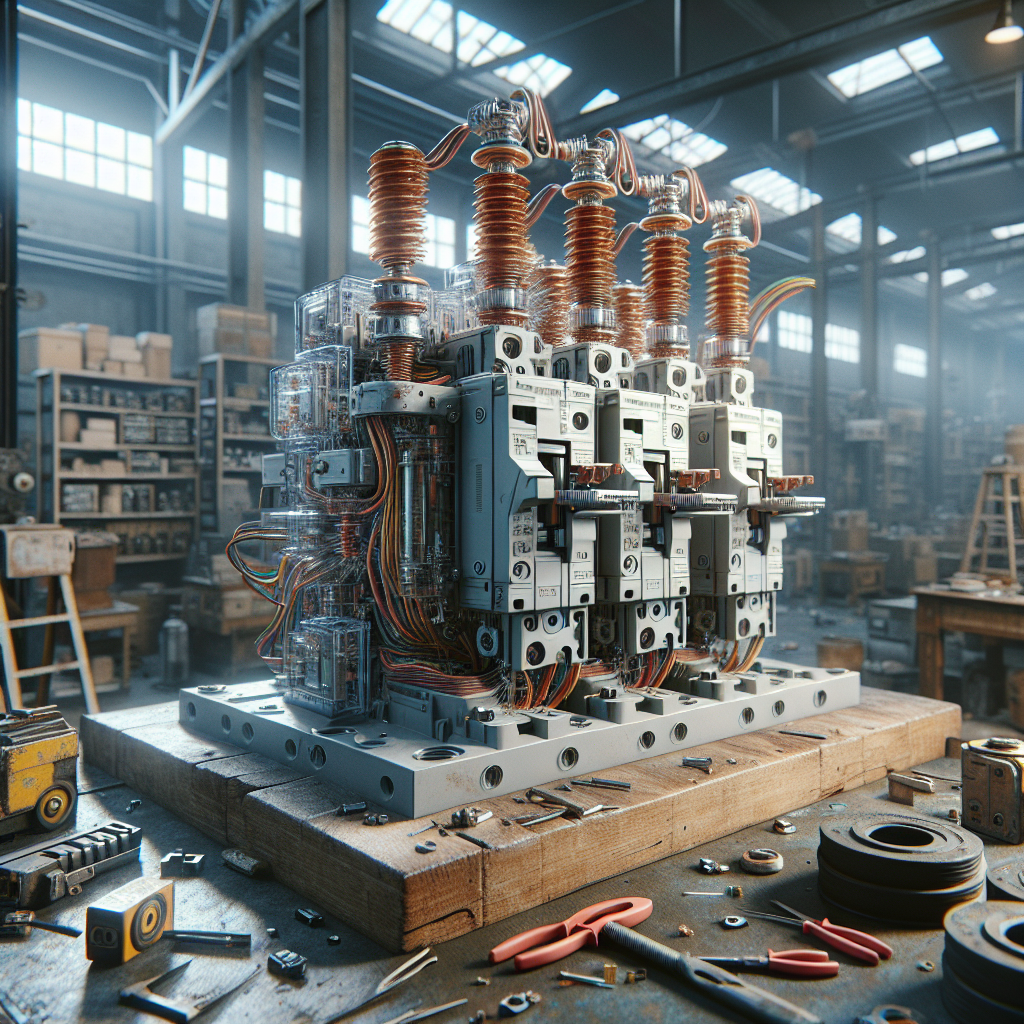

Air Blast Breakers are specialized circuit breakers. They utilize a blast of compressed air to extinguish the electric arc when the circuit is broken.

Think of it as a firefighter of sorts, extinguishing the electrical ‘fire’ during a circuit disruption. This crucial tool helps keep the construction site safe and efficient.

Understanding the Function of the Air Blast in Construction

In the field of construction and several other industries, the term ‘air blast’ carries critical significance. Misunderstanding its function can detrimentally affect the overall efficiency and safety of a job. So, what exactly is the function of the air blast?

The Definition of Air Blast

Essentially, an air blast refers to a powerful blast or gust of air produced artificially. It’s used in a variety of applications, one of those being the construction sector, particularly in the application of blasting rock and other hard elements, in surface cleaning, and airblast sprayers.

Applications of Air Blast in Construction

The versatility of the air blast tool makes it a must-have in any serious construction arsenal. Its primary uses are as follows:

- Rock blasting

- Surface cleaning

- Applying sprayers or coatings

1. Rock Blasting

Air blast plays a crucial role in rock blasting, where shock waves generated by explosives are used to fragment rock, then, the resulting rock fragments are removed by the air blast produced. This application is commonly found in mining and quarrying operations.

2. Surface Cleaning

Another common use of Air blast is in surface cleaning. It is applied to remove dirt, grime, paints, and other unwelcome substances from surfaces, preparing them for further finishing or painting.

3. Applying Sprayers or Coatings

When it comes to applying sprayers or coatings, air blast sprayers provide efficient and uniform application. This is particularly useful in purposeful, protective coatings in construction.

The Impact of Air Blast

The influence of the air blast extends well beyond construction, and its contribution towards efficiency and sustainability in the industry has been regarded as crucial. According to a study published in the Construction and Building Materials Journal, using an air blast can reduce the energy consumption of key construction processes by up to 50%.

In conclusion, the function of the Air Blast in construction spans across various applications, making it a multi-functional tool that contributes significantly to efficiency in the industry.

Diving Deeper into the World of Air Breakers

Just as ‘air blast’ carries its weight in the construction world, another term worth highlighting is ‘air breaker.’ Essentially, an air breaker is a type of circuit breaker that utilizes air as an insulating material. Let’s delve deeper into this critical piece of machinery.

Unveiling the Air Breaker

An air breaker, also known as an air circuit breaker (ACB), is an overcurrent protection device that uses air as the dielectric medium to quench the arc when the high voltage circuit is broken. Employed in both low and high-voltage networks, air breakers prevent damage to the circuit that can occur due to excessive current from an overload or short circuit.

The Intricacies of Operation

Here’s how an air breaker performs its function. Like any circuit breaker, it detects a fault condition and subsequently interrupts the flow of current to protect the electrical circuit. When an overload or short circuit occurs, the air breaker breaks the connection and a ‘trip’ mechanism is activated. Once the fault has been addressed, it can be manually or automatically reset to its usual operation.

The Varied Uses of Air Breakers

The versatility of an Air Breaker makes its applications quite extensive. Here are some of its critical uses:

- Power generation plants

- Electrical substations

- Industrial and large buildings

1. Power Generation Plants

Exceptionally high currents flow through power generation plants. As such, the ACBs are installed to protect the electrical circuits from getting damaged due to an overcurrent or short-circuit condition, thereby ensuring smooth, undisrupted functioning.

2. Electrical Substations

Electrical substations, which are intermediary stations in the power supply grid, rely on air circuit breakers to prevent electrical faults. These breakers also support the efficient distribution of electricity.

3. Industrial and Large Buildings

In most substantial industrial structures and large buildings, air circuit breakers are utilized. They regulate high-value electric loads and protect the circuitry, ensuring the safety of the entire electrical system.

Importance and Impact of Air Breakers

Air breakers are instrumental in maintaining the overall integrity and safety of an electrical circuit, particularly in an industrial environment. According to a report by Grand View Research, the growing emphasis on efficient and reliable power supply is further driving the demand for air circuit breakers. Therefore, recognizing the role and function of an air breaker is crucial in relevant industries.

In a nutshell, the air breaker, like the air blast, is a multifunctional tool vital to safe and effective operations in its respective field.

Comparing Air Breakers and Oil Circuit Breakers

While the functionality of both air breakers and oil circuit breakers remains the same i.e safeguarding the electronic circuits against damages induced by overcurrent or short circuits, there are key differences in their operation, applications, and overall effectiveness. This discussion aims to explore the differences between the two and determine which one is better.

Understanding Oil Circuit Breakers (OCB)

Oil Circuit Breakers, similar to air breakers, are overcurrent protection devices but use mineral oil or other insulating oil as an interrupt medium instead of air. When high voltage circuit is broken, the arcing is extinguished by the insulating oil which turns the ionized gas back into its original state. This prevents excessive sparking and eliminates the danger of fire or explosion. Oil circuit breakers are mostly used in power distribution networks.

The Operational Differences

When an overload or short circuit occurs, an oil circuit breaker breaks the circuit and shifts the arc to a chamber filled with oil. The intense heat of the arc vaporizes the oil and creates a gas shield, restricting the arc. Once the arc is extinguished, the oil cools and transforms into its liquid state, thereby providing a fresh supply of oil for the next operation.

On the other hand, air circuit breakers use air as the medium to detach the arc. When a short circuit or overload occurs, the breaker trips and detaches the circuit. This action produces an arc in the air, which is then cooled and dispersed by the surrounding air, breaking the circuit.

Advantages and Disadvantages

Just like any tool, air circuit breakers and oil circuit breakers have their strengths and weaknesses. Here is a brief summary:

Air Circuit Breakers

- One of the most substantial advantages of ACBs is the reduced fire risk as compared to OCBs, due to the use of air as an interrupt medium.

- Another significant benefit is their capacity for high current ratings and high fault current withstands capacity.

- However, ACBs are prone to mechanical wear and tear as they rely on air for the extinction of the arc which might not be as effective as oils.

Oil Circuit Breakers

- The key advantage of using oil as an arc extinguishing medium lies in its high cooling effect, promoting better interrupting performance.

- OCBs are also less prone to wear and tear due to the reapplied layer of oil for every operation.

- However, oil presents the risk of a fire hazard, particularly in enclosed spaces.

- Another downside is the maintenance and replacement cost of oil, especially if the oil gets contaminated or loses its dielectric strength.

Which is better Air Circuit Breaker or Oil Circuit Breaker?

Deciding which circuit breaker is superior depends largely upon application specifics, risk tolerance and maintenance resources. Air Circuit Breakers (ACB) are preferred due to their low fire risk, making them ideal for installations in proximity to flammable materials or enclosed spaces. In contrast, Oil Circuit Breakers (OCB) exhibit superior arc extinguishing capabilities due to the use of oil but are accompanied by a higher fire risk and require regular oil maintenance.

So, while each breaker has its own set of advantages and disadvantages, the choice will typically be dictated by the specific requirements of the situation at hand.

Introduction to Air Blast Circuit Breakers

Building on the insightful discussions about air breakers and oil circuit breakers, we delve into the realm of another commonly used circuit breaker: the Air Blast Circuit Breaker. Equipped with mechanisms nearly identical to the Air Circuit Breakers, the Air Blast Circuit Breaker differs in that it uses a blast of high-pressure air to extinguish the arc formed in circuit-breaking, hence its name.

Unpacking the Air Blast Circuit Breaker

The Air Blast Circuit Breaker (also known as an “air blast”), similar to the Air Circuit Breaker, uses air as its arc quenching medium. However, it quenches the arc by blasting a high-pressure air stream towards the arc during the circuit-breaking process. This high-pressure air blast rapidly decreases the ionization around the arc, cooling and extinguishing it, thereby interrupting the circuit flow.

Operating Principle of Air Blast Circuit Breakers

When a fault is detected in the circuit, the trip coil in the Air Blast Circuit Breaker activates a mechanism which causes the moving contacts to separate. As these contacts separate, an arc is created due to ionization of the air between the contacts. The high-pressure air stream, directed towards this arc, de-ionizes the air around it, leading to arc extinction and circuit interruption. After this, the breaker is reset to its normal operation.

Key Applications of Air Blast Circuit Breakers

Owing to their unique characteristics, these specialized breakers have found fertile applications in some specific sectors. Here are some of them:

- High-voltage transmission lines

- Electrical power stations

- Substations for power distribution

1. High-voltage Transmission Lines

Where high voltages are involved, Air Blast Circuit Breakers have proven to be very effective. They are often used to protect high-voltage transmission lines from damage due to fault currents.

2. Electrical Power Stations

Similar to Air Circuit Breakers, Air Blast Circuit Breakers also find a role in power stations for controlling and limiting high currents, thereby guaranteeing the smooth and uninterrupted functioning of the stations.

3. Substations for Power Distribution

Substations often employ Air Blast Circuit Breakers to ensure the efficacious flow of electricity along the various feeders and busbars. They act as protective devices, preventing any potential fault occurrence from causing catastrophic damages to the electrical circuit.

Benefits and Drawbacks of Air Blast Circuit Breakers

Like all tools and machines, Air Blast Circuit Breakers too come with their set of pros and cons:

Advantages of Air Blast Circuit Breakers

- Significantly faster operation speed which is perfect for handling high fault currents

- Reduced maintenance needs as there are no oil or gas mediums whose properties might change over time

- Very low chances of fire ignition owing to the non-flammable air medium

Disadvantages of Air Blast Circuit Breakers

- High air pressure requirement, necessitating the need for an air reservoir or air compressor

- Less reliable in nature as compared to oil circuit breakers, as the interruption process is affected by humidity and other atmospheric conditions

- Greater mechanical stress due to high-pressure air flow, which may lead to faster wear and tear of parts

Comparison: Air Circuit Breaker (ACB) vs Air Blast Circuit Breaker

While the ACB and air blast circuit breaker seem similar, as they both use air as the arc suppression medium, some operational differences set the two apart:

Air Circuit Breaker Vs Air Blast Circuit Breaker: What’s the Difference?

In an Air Circuit Breaker, the arc is extinguished naturally as the air surrounding it cools and de-ionizes it. On the other hand, an Air Blast Circuit Breaker uses a high-pressure air stream to rapidly extinguish and cool the arc. Thus, the latter has a much higher breaking speed and can handle higher fault currents comparatively.

Comprehensive Comparison Table

| Parameter | Air Circuit Breaker (ACB) | Air Blast Circuit Breaker (Air Blast) |

|---|---|---|

| Method of Arc Quenching | Natural de-ionization and cooling of the arc by surrounding air | Rapid de-ionization and cooling of the arc by high-pressure air stream |

| Breaking Speed | Medium | Very High |

| Fire Risk | Very Low | Very Low |

| Handling of High Currents | Handles relatively moderate currents | Adept at handling very high fault currents |

| Maintenance Requirements | Relatively Low | Requires occasional servicing due to wear and tear caused by the high pressure air blast |

In conclusion, both the ACB and the air blast circuit breaker are instrumental in different sectors due to their varying characteristics. The choice of circuit breaker ultimately depends on the specific requirements and circumstances at hand.

In concluding, we’ve found that the role of the air blast in construction serves as a key player in the pursuit of efficiency and safety. Its versatility spans rock blasting, surface cleaning, and the application of sprayers or coatings. As a tool, it stands tall among its counterparts not only for its diverse usage but also for its impact in decreasing energy consumption by nearly half.

From our perspective, understanding and integrating the function of the air blast in construction practices can enhance effectiveness, energy saving and ultimately lead to a sustainable working environment. So, it’s crucial to comprehend this powerful tool’s contributions to the construction industry. It’s safe to say, the air blast is indeed an unsung hero in the construction universe.