Intro To the Cement Spacing Factor

The cement spacing factor (CSF) is an essential construction term that requires attention. It refers to the gap or space filled with cement between the casing and the borehole in a well construction.

This technical variable plays a crucial role in well integrity. It ensures stability and reduces the risk of structural failure. Moreover, the CSF prevents detrimental environmental impacts like ground contamination.

In its practical application, accurate calculation and application of the CSF can lead to long-term durability and safety in construction projects. The correct CSF offers a foundation for solid and long-lasting structures.

Table of Contents

Understanding the Spacing Factor for Concrete

What Is The Spacing Factor?

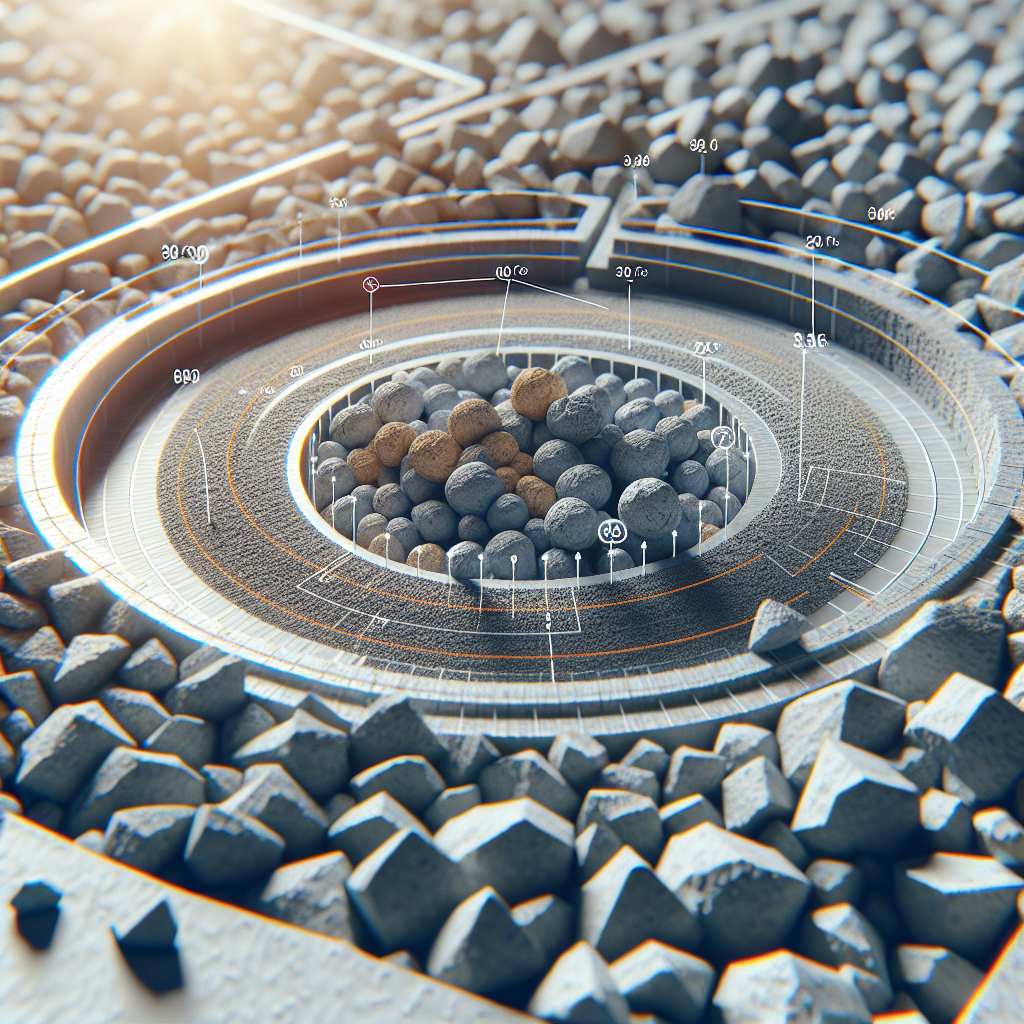

In the simplest of terms, the spacing factor is a measurement used to evaluate the distance between the particles of cement paste within the concrete. This is closely related to the concentration and connectivity of the paste’s microscopic pores, which impact not only the strength but also the permeability of the concrete.

Importance of Spacing Factor in Concrete

The spacing factor plays a fundamental role in controlling the rate of chloride diffusion into concrete, which is crucial for the durability and longevity of concrete structures particularly in environments where deicing salts get used or in marine conditions. A lower spacing factor indicates that the capillary pores are smaller and more closely spaced, which leads to decreased permeability, improving the long-term performance of the concrete [source].

How Is Spacing Factor Calculated?

The spacing factor is usually calculated using the Powers model, an empirical model proposed by T.C. Powers in the 1960s. By this calculation, it is primarily influenced by water-cement ratio and air content. Other factors like aggregate characteristics and admixtures may also impact the spacing factor indirectly.

Key Factors Impacting Spacing Factor

There are several key parameters that can influence the spacing factor of concrete. These include:

- Water-cement ratio: The proportion of water to cement in the mix significantly impacts the porosity and hence the spacing factor.

- Air content: The volume of entrained air alters the pore structure of the cement paste which in turn affects the spacing factor.

- Aggregate characteristics: By modifying the packing of the cement paste, the shape and size distribution of aggregates can indirectly impact the spacing factor.

- Admixtures: Certain chemical and mineral additives can affect the hydration reactions, which in turn alters the microstructure of the cement paste and affects the spacing factor.

| Parameter | Impact on Spacing Factor |

|---|---|

| Water-cement ratio | Higher ratio, higher spacing factor |

| Air content | Higher air content, higher spacing factor |

| Aggregate characteristics | Varies with size and shape |

| Admixtures | Varies with type and concentration |

Diving Deeper into the Concept of Spacing Factor in Concrete

The Science Behind the Spacing Factor

In essence, the concrete spacing factor aids in comprehending the structure of cement paste at a microscopic level. This understanding remarkably contributes to predicting significant properties of the concrete, like strength, durability and porosity. It is crucial to mention here that the assessment of the spacing factor involves various scientific methods which reveal the continuity and interconnectivity of the pores within the paste (source).

Impact of Spacing Factor On Durability of Concrete

In addition to managing the rate of chloride diffusion, the spacing factor in concrete also plays a significant role in determining the degree to which concrete may be impacted by various aggressive agents including freeze-thaw cycles, alkali-silica reaction, sulfates, among others (source). An optimal spacing factor in a concrete mix can therefore lead to enhanced resistance to these agents, resulting in prolonged service life of the concrete structures.

Parameters Associated With Calculating Spacing Factor

Beyond the Powers Model, the spacing factor can also be calculated using newer, advanced computational models that are able to provide a more customized analysis by integrating various additional factors such as time, curing conditions, type of cement, etc. These newer models have opened doors to an even broader understanding of spacing factor in concrete (source).

External Factors Modifying the Spacing Factor

Apart from key parameters like water-cement ratio, air content, aggregate characteristics, and admixtures, other poker factors can also significantly influence the spacing factor:

- Curing Conditions: The spacing factor can change with different curing procedures. For instance, a moist curing condition has been found to result in a reduced spacing factor as compared to air curing.

- Type of Cement: Different types of cement have different hydration characteristics, thereby altering the spacing factor.

- Mixing Process: The intensity, duration and pattern of mixing can influence the dispersion of the cement particles and thus, affect spacing factor.

| External Factor | Influence on Spacing Factor |

|---|---|

| Curing Conditions | Varies with different curing procedures |

| Type of Cement | Varies with hydration characteristics |

| Mixing Process | Impacts dispersion of cement particles |

To reiterate, the spacing factor’s profound impact on the durability and structural integrity of concrete makes it an integral part in the planning and execution of concrete mixes. A comprehensive understanding of the spacing factor is imperative to build sustainable, long-lasting structures.

Exploring the Role of Air Content in Concrete

What Is Air Entrainment?

Air entrainment, or the intentional creation of tiny air bubbles in concrete, is a critical factor that affects the longevity and durability of the concrete structure.

While the spaces left behind by air bubbles undoubtedly alter the overall spacing factor in the concrete mixture, these can also influence strength, workability, and the material’s resistance to weathering and chemical attack.

Why is Air Content in Concrete Important?

Incorporating air into a concrete mixture creates an interconnected network of voids that allows for the contraction and expansion of water within the concrete. This reduces the risk of catastrophic failure during freeze-thaw cycles, improving overall durability. Also, entrained air can improve workability and cohesion in the fresh concrete mix, leading to better quality concrete placements (source).

Impact of Air Content on Spacing Factor

An increase in air content generally means an increase in the spacing factor, as air voids manifest as larger and more widely dispersed capillary pores in the concrete. This can boost permeability, which might lead to compromised strength and durability unless the size and distribution of these air voids are carefully managed.

Acceptable Air Content Range in Concrete

The recommended air content in concrete ranges from 4 to 7 percent for concrete that will be exposed to freeze-thaw conditions and de-icing chemicals. For non-air-entrained concrete, the total air content should be less than 2 percent (source). The exact amount usually depends on a combination of factors, including the desired workability of the concrete, the size and gradation of the aggregate, and the environmental conditions to which the concrete will be exposed.

Monitoring and Adjusting Air Content in Concrete

Maintaining and adjusting air content in concrete during the mixing process is critical. Several methods can be used to measure the air content in both the fresh and hardened state, such as pressure methods, volumetric methods and the hardened air void system analysis.

- Admixtures: Air-entraining admixtures can be added to control the creation of air voids.

- Modified Mixing Process: Care should be taken during the mixing process as excessive or insufficient mixing can alter the targeted air content.

- Appropriate Sizing of Aggregates: Proper size and distribution of aggregates can aid in maintaining the air content within acceptable limits.

| Method | Purpose |

|---|---|

| Admixtures | Controls the creation of air voids |

| Modified Mixing Process | Avoids drastic shifts in air content |

| Appropriate Sizing of Aggregates | Maintains the air content within limits |

The balance of the air content in concrete significantly influences the performance characteristics of the final product, including its reliability, durability and sustainability. A thorough understanding of air content and its impact on the spacing factor is integral to the successful production of competent and durable concrete structures.

Wrapping It All Up

After unpacking the ins and outs of the spacing factor for concrete, we’ve found that its understanding is critically significant for the durability and longevity of concrete structures. As seen, the spacing factor is not just a single component; rather, it is a complex amalgamation of the water-cement ratio, air content, aggregate characteristics, and admixtures, all of which influence concrete’s structural integrity in varying ways.

From our perspective, taking into account the spacing factor in the concrete design process allows for a proactive approach to achieve improvements in the concrete’s long-term performance and adjust to different environmental conditions, such as deicing salts or marine exposure. Spacing factor calculation, therefore, becomes an essential tool for engineers and contractors to ensure the excellent quality and sustainability of their concrete structures.