Introductory Gist on Flex Mortar in Construction

How often have you wondered about the secret behind the longevity and resilience of structures? Today, I’d like to share an insight into a key player in the construction industry: Flex Mortar.

As its name suggests, flex mortar is a type of mortar known for its superior flexibility. Besides its elasticity, it lends excellent adhesion, making it instrumental in securely placing tiles. But that’s not all. In the paragraphs to follow, we’ll explore its properties, understand its various applications, and learn some tips for its application. We’ll also compare flex mortar with standard mortar and examine what makes the former a popular choice in construction.

So, are you ready to uncover the mystery behind flex mortar? Let’s get started!

Understanding the Use of Flex Mortar in Construction

Introduction to Flex Mortar

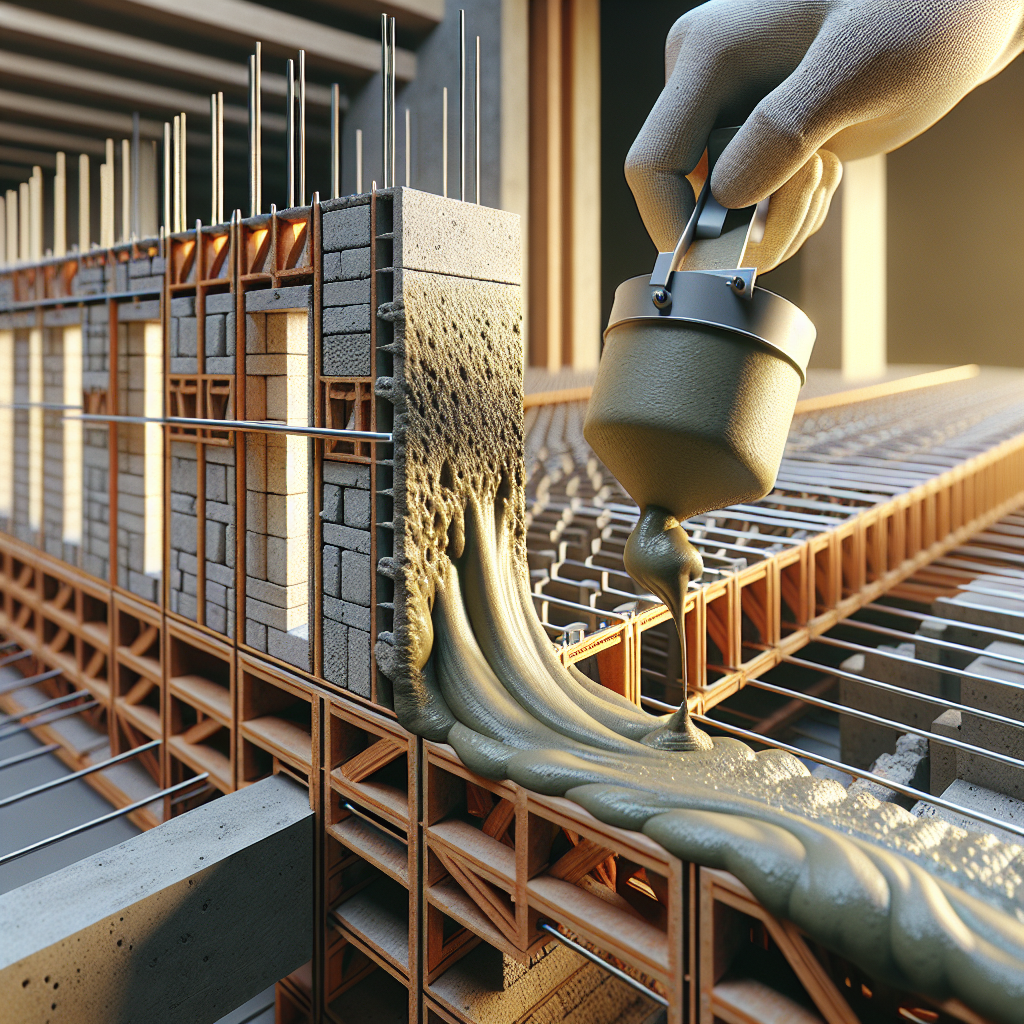

Flex mortar is a composite building material widely used in construction for its superior flexibility and adhesive properties. It’s specially formulated to accommodate movement and thermal expansion in ceramic tiles and natural stones.

Key Properties of Flex Mortar

- High elasticity helps prevent cracks.

- Excellent adhesion promotes secure tile placement.

- Resistant to water and temperature fluctuations.

- Suitable for both interior and exterior applications.

Where Is Flex Mortar Used?

Flex mortar is primarily employed in specific situations where standard mortar may not suffice:

- Heated Flooring Systems: Ideal for underfloor heating, flex mortar prevents tile cracks due to thermal cycling.

- Moisture-Prone Areas: Because of its water resistance, flex mortar is perfect for bathrooms, kitchens, and swimming pools.

- Outdoor Installations: The flexibility and durability make it optimal for patios, balconies, and terraces exposed to varying weather conditions.

- Large-Format Tiles: It is suitable for use with large tiles which require additional support due to their weight and dimensions.

Application Tips for Flex Mortar

While using flex mortar, consider the following:

- Always mix according to the manufacturer’s guidelines to ensure optimal performance.

- Allow adequate time for curing; avoid heavy traffic until the mortar is fully set.

- Ensure surface compatibility: flex mortar can be used on concrete, cement board, and proper backer substrates.

Comparing Flex Mortar with Standard Mortar

| Property | Flex Mortar | Standard Mortar |

|---|---|---|

| Elasticity | High | Low |

| Water Resistance | High | Medium |

| Application Areas | Both interior and exterior, specialized conditions | Primarily interior, general usage |

Conclusion

Understanding the distinct applications and benefits of flex mortar can significantly enhance the longevity and performance of your construction projects. For more detailed insights and guidelines, consult a comprehensive resource like This Old House, which provides practical advice on building materials and techniques.

Exploring the Components of Flex Mortar

What Makes Flex Mortar Flexible?

Flex mortar’s increased flexibility compared to standard mortar is largely derived from special additives present in its formulation. These additives might include polymers like latex or other types of flexible synthetic resins. Addition of these components dramatically improves the mortar’s ability to withstand physical stress and temperature fluctuations without cracking or losing adhesive strength.

Flex Mortar Components

A typical flex mortar might include:

- Portland cement: A common ingredient in most mortars and concretes, Portland cement forms the basic structural matrix of the product.

- Special Additives: The inclusion of synthetic polymers or similar compounds greatly enhances the flexibility of the mortar.

- Aggregate: As with traditional mortar, aggregate materials give bulk and body to flex mortar. These typically include finely ground stones or sand.

- Water: As in all cement mixes, water activates the cement and allows the product to be worked and applied.

In-Depth Look at Flex Mortar Application Tips

Surface Preparation for Flex Mortar

Before applying flex mortar, a key facet to consider is proper surface preparation:

- Cleanliness: The area to be mortared should be clean and free of dust, grease, or other loose particles that could impair adhesion.

- Moisture: The surface should ideally be slightly damp, but not overly wet. This can help achieve a better bond.

- Condition: The surface should be in sound condition; any crumbling or weak points should be addressed prior to application.

Safety Tips When Using Flex Mortar

Handling flex mortar, like any other construction material, requires certain safety precautions:

- Protective Equipment: While mixing and applying flex mortar, it’s advisable to wear protective equipment such as gloves, goggles, and a dust mask.

- Ventilation: If working indoors, ensure you have enough ventilation. While flex mortar isn’t typically highly toxic, it’s always better to maintain good airflow.

- Proper Disposal: Unused mortar and cleanup water should be disposed of responsibly, in compliance with local regulations.

Further Comparing Flex Mortar and Standard Mortar

Cost Differences

An important factor to consider when choosing between flex mortar and standard mortar is cost. Due to its specialized formulation and additives, flex mortar is often more expensive than its standard counterpart. Therefore, while flex mortar may be superior in terms of performance characteristics, the additional cost could be prohibitive for some projects.

Considerations for Bulk Purchasing

When purchasing flex mortar in bulk for larger projects, consider:

- Storage conditions: Flex mortar should be kept in a cool and dry location.

- Shelf life: Use the mortar before the manufacturer’s recommended expiry date to ensure its performance.

- Measurements: Accurately measure the quantities required to avoid wastage or shortage.

That said, when it comes to understanding the potential benefits and considerations of flex mortar, no resource will offer more comprehensive advice than This Old House.

What is the Best Flexible Mortar Mix?

Choosing the Right Flexible Mortar Mix

Selecting the best flexible mortar mix depends on your specific project requirements, the conditions under which the mortar will be used, and the materials involved. Here are a few criteria to aid your decision-making:

- Type of Tiles or Stones: Determine if you are working with ceramic, porcelain, or natural stone as different blends may be best suited for these materials.

- Environmental Conditions: Consider whether the mortar will be exposed to moisture, temperature fluctuations, or direct sunlight.

- Surface Compatibility: Choose a mix that adheres well to the substrate material such as concrete, wood, or cement board.

Popular Brands and Products

A few recognized brands offer high-quality flexible mortar options. Ensure you review product specifications and consult with retailers to find the best fit for your needs.

- Mapei: Known for its diverse range of adhesive products, offering mortar mixes suitable for a variety of applications.

- Laticrete: Offers flexibility-focused products that cater to both residential and commercial environments.

- Custom Building Products: They provide a variety of flexible mortar solutions tailored to different tile and stone installations.

Key Features of a Good Flexible Mortar Mix

When evaluating specific mixes, look for these essential features:

- Polymer Enrichment: Ensures high elasticity, preventing cracks in tiled surfaces.

- Waterproofing Abilities: Essential for installations in bathrooms, pools, and outdoor areas.

- Easy Mixing and Application: Smooth workability is crucial for achieving a level and consistent application.

It’s important to reference well-regarded resources when selecting building products. For additional insight on choosing mortar mixes, consulting a guide from This Old House can be invaluable.

Understanding the Difference Between Thin Set Mortar and Regular Mortar

Thin Set Mortar Basics

Thin set mortar is a type of adhesive mortar made from a blend of cement, fine sand, and a water retention compound that allows the cement to properly hydrate. Commonly used for installing ceramic tiles, thin set mortar provides a strong bond in a thin application—usually no more than 3/16 inch thick.

- Composition: Includes cement, sand, and polymers for improved flexibility and adhesion.

- Usage: Ideal for setting tiles on walls and floors, primarily for residential and light commercial applications.

- Application Thickness: Typically 3/16 inch or less, providing a thin yet effective adhesive layer.

Regular Mortar Fundamentals

Regular mortar, often referred to as thick set or simply mortar, consists of sand, a cementing material like Portland cement or lime, and water. It’s primarily used for construction applications such as laying bricks and stone.

- Composition: Generally made with a mixture of sand, cement, and lime.

- Utilization: Used for building block and stone walls, and other structural components.

- Application Thickness: Typically applied thicker than thin set, often in layers of at least 3/8 inch.

Key Differences Between Thin Set and Regular Mortar

The primary differences between thin set mortar and regular mortar lie in their composition, application, and suitability for various uses.

| Feature | Thin Set Mortar | Regular Mortar |

|---|---|---|

| Primary Use | Tile installations | Structural work with bricks and stones |

| Application Thickness | Up to 3/16 inch | Typically 3/8 inch or more |

| Adhesive Properties | High adhesion for tiles | Lower adhesion, primarily structural bond |

| Composition Additives | Polymers for flexibility | Lime for binding |

Choosing the Right Mortar for Your Project

Selecting between thin set and regular mortar largely depends on the specifics of the construction task at hand:

- Tile Installation: Opt for thin set mortar due to its adhesive properties and suitable thickness.

- Brick and Stone Walls: Regular mortar is better suited for its thicker application and structural integrity.

- Weather Resistance: Consider flex or thin set mortar with supplemental additives for outdoor tile applications for their enhanced durability.

For a trusted source on selecting the correct mortar for your project, check resources like This Old House, which offers reliable guidance on various building materials.

Conclusion: The Key Benefits and Applications of Flex Mortar

In conclusion, Flex mortar is an essential building material that provides a new level of durability, adaptability, and security in construction work. It excels in areas where standard mortar falls short due to its flexibility, water and temperature resistance, and ability to handle large-format tiles.

Notable applications of flex mortar include heated flooring systems, moisture-prone areas, outdoor installations, and large-format tiles. This versatile material’s properties are made possible by its composition, which includes special additives – typically polymers that enhance flexibility and thermal stability.

Choosing between standard mortar and flex mortar depends on the specific needs of your project. When additional elasticity, water resistance, and flexibility are required, flex mortar proves to be the superior choice. Additionally, understanding the differences between different mortars such as thin set and regular mortar can significantly shape project outcomes. Consult reliable resources like This Old House for further insights and advice.

Frequently Asked Questions – FAQs

What is flex mortar used for?

Flex mortar is primarily used in construction situations where standard mortar may not be efficient, such as heated flooring systems, moisture-prone areas, outdoor installations, and large-format tiles. Its high elasticity and excellent adhesion make it ideal for these applications.

What are the key properties of flex mortar?

Flex mortar is known for its high elasticity, excellent adhesion, resistance to water and temperature fluctuations, and suitability for both interior and exterior applications.

What makes flex mortar flexible?

Flex mortar’s flexibility comes from special additives in its formulation, typically polymers, which help the mortar to withstand physical stress and temperature fluctuations without cracking or losing adhesive strength.

How does flex mortar compare to standard mortar?

Flex mortar has higher elasticity and water resistance compared to standard mortar. It can be used for both interior and exterior applications, particularly under specialized conditions, while standard mortar is typically used for general interior applications.

Is flex mortar more expensive than standard mortar?

Yes, due to its specialized formulation and additives, flex mortar is often more expensive than its standard counterpart.