Introduction

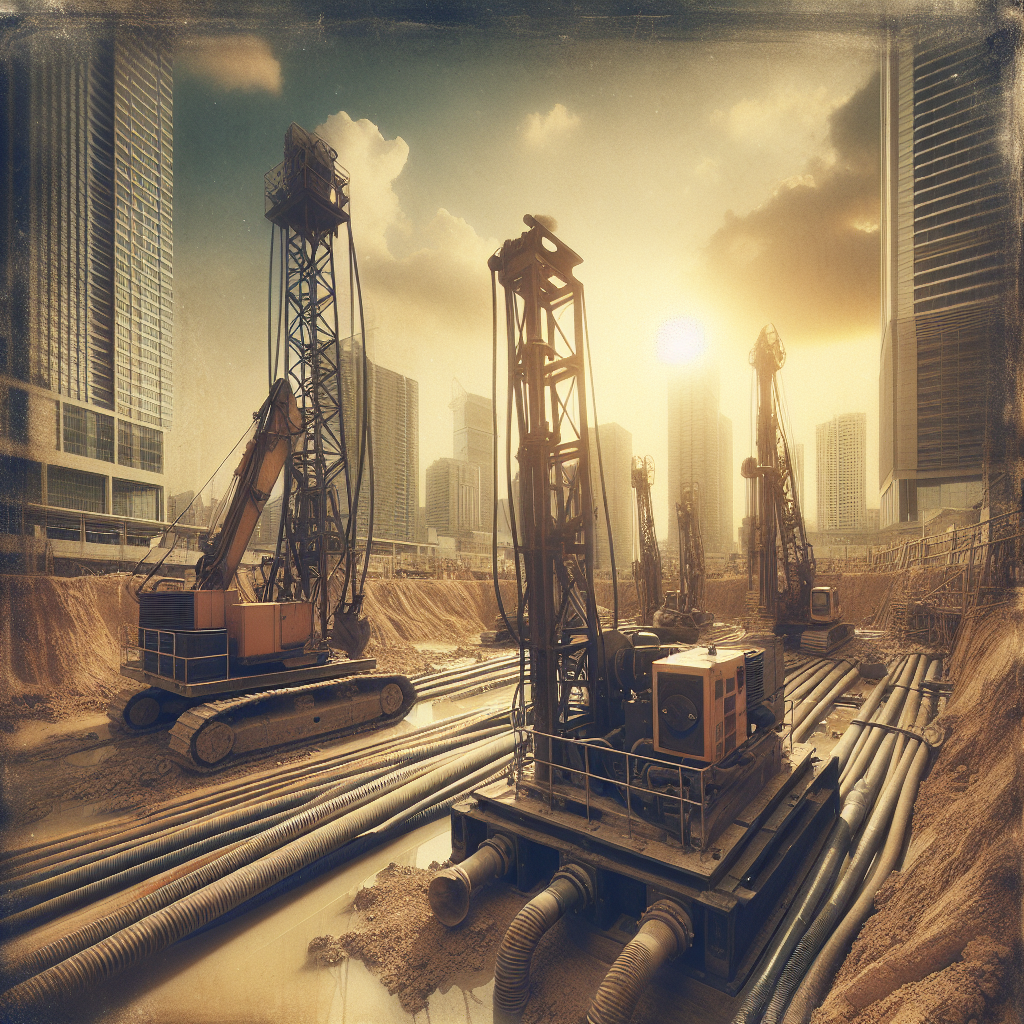

Every construction worker knows the struggle of managing groundwater. Did you know, according to a report by Imagine H2O and 11th Hour Project, almost $64bn has to be spent annually to manage water infrastructure in the US? In this blog post, we’re going to unravel the somewhat complicated, but incredibly important, concept of dewatering in excavation. We’ll explore its meaning, the array of methods used, its significance, factors that influence which method is used, and plenty more! Ready to get started?

Why Is Dewatering Important?

Dewatering is essential for several reasons:

- Prevents soil erosion.

- Reduces the risk of hazards, like flooding.

- Ensures the stability of excavation walls.

- Allows for safe and dry working conditions.

Dewatering is an essential part of the excavation process, ensuring that sites remain safe, efficient, and environmentally compliant. It encompasses various techniques, each suited to different conditions and influenced by factors like soil type, water table level, excavation depth, and environmental impact.

Dewatering pumps play a significant role, requiring careful selection based on the volume of water, its type, and the power source availability. Understanding the key differences between water pumps and dewatering pumps is crucial for optimal choices.

The implementation of dewatering systems in construction showcases their critical function in minimizing groundwater impact, ensuring foundation stability, reducing delays, and managing costs effectively. Furthermore, keeping pace with technological advancements in dewatering can provide enhanced efficiency and sustainability, while addressing common challenges essential to maintain operational productivity and environmental responsibility.