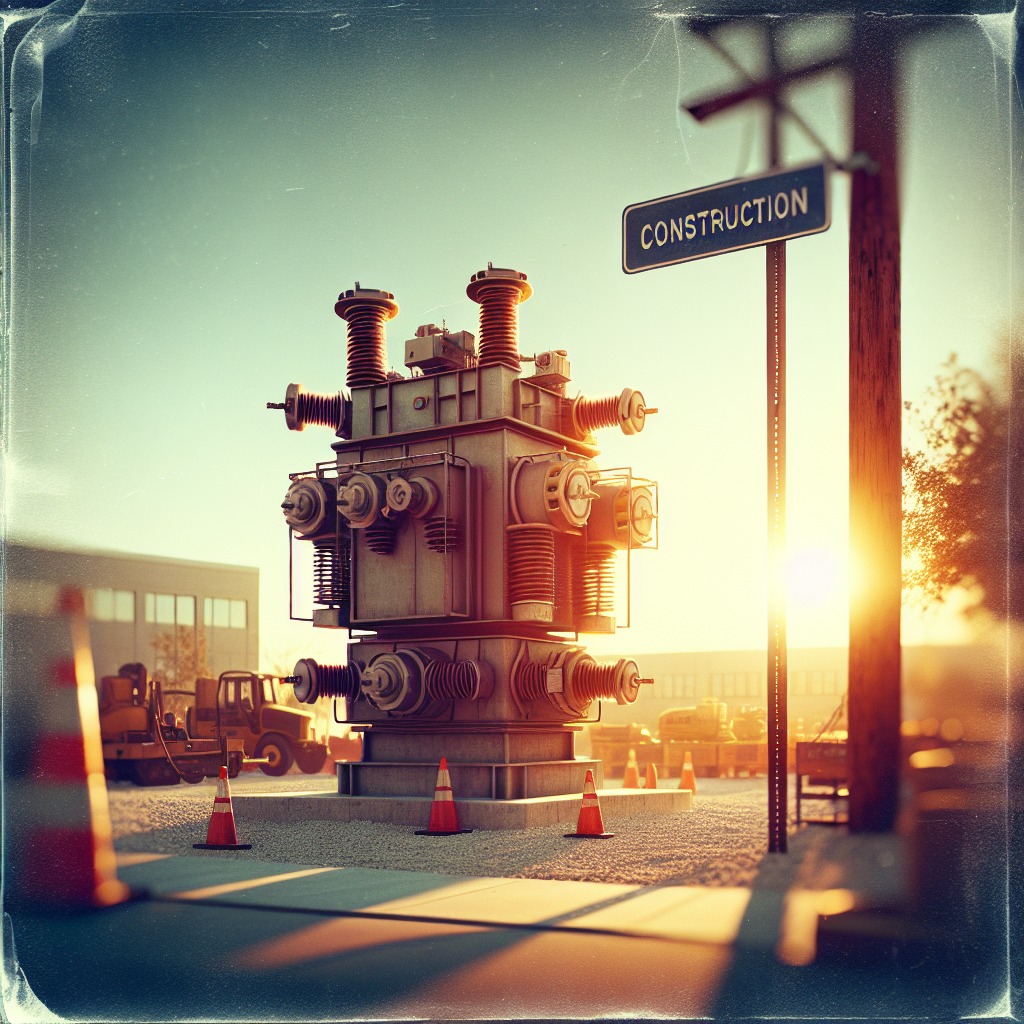

Introduction to Static VAR Compensators (SVCs) in Construction

Do you wonder how your power supply stays stable, allowing all your electronics to run smoothly? Do your eyes glaze over when you hear words like “voltage control” or “reactive power?”

Well, this article is for you!

We’re exploring the world of Static VAR Compensators (SVCs) – those amazing devices that keep the electricity flowing just right in our power systems. We’ll learn about their function, main components, and their benefits. Also, we’ll look into their application in various environments like industrial plants, electric utilities, and renewable energy systems.

So why don’t we get started?

Strap in, and let’s uncover the secrets of SVCs!

Table of Contents

Understanding Static VAR Compensators in Construction

Overview of Static VAR Compensator

A Static VAR Compensator (SVC) is a device used in electrical power systems to manage voltage control and improve the quality of electricity. It dynamically adjusts the reactive power to stabilize voltage levels within the power grid.

Main Components of a Static VAR Compensator

An SVC typically consists of several key components:

- Thyristor-Controlled Reactors (TCRs): Adjust the inductive reactance.

- Thyristor-Switched Capacitors (TSCs): Adjust the capacitive reactance.

- Control System: Monitors the power network and controls the switching of TCRs and TSCs.

Functions of a Static VAR Compensator

An SVC helps in several important aspects:

- Voltage Stabilization: Maintains steady voltage levels across the grid.

- Power Factor Correction: Improves efficiency by reducing energy losses.

- Load Balancing: Distributes electrical load more evenly in the network.

Benefits of Using a Static VAR Compensator

Using an SVC offers various benefits:

- Improved Efficiency: Enhances the overall efficiency of the power system.

- Reduced Downtime: Minimizes the risk of outages and equipment failures.

- Cost Savings: Lowers energy costs by optimizing power usage.

Examples of Static VAR Compensator Applications

SVCs are widely used in various environments:

- Industrial Plants: Maintains consistent power supply for machinery.

- Electric Utilities: Provides stable power for residential and commercial users.

- Renewable Energy Systems: Balances power fluctuations from wind and solar sources.

For more detailed information, you can refer to resources such as General Electric, which provides extensive explanations and benefits of SVCs in power systems.

Additional Advantages of Static VAR Compensators

Enhancing Grid Resilience

Beyond just correcting power factor and voltage stabilization, SVCs also contribute significantly to grid robustness. They achieve this by bolstering the grid’s ability to withstand varying loads and the intermittent nature of some power sources. Thus, they contribute to the reliability and stability of power networks.

Extending Equipment Lifespan

By managing voltage and eliminating power surges, SVCs can extend the lifespan of other connected electrical equipment. This reduction of wear and tear can save substantial costs associated with equipment maintenance and replacement over time, particularly in industries with high electricity usage.

Choosing the Right SVC

When selecting an SVC for a particular application, several factors should be considered:

- Load Type: The type of load (resistive, inductive, or capacitive) will determine the type of compensator needed.

- Grid Characteristics: The size, voltage level, and layout of the grid can influence the SVC’s effectiveness.

- Environments: The physical and climatic conditions where the SVC will be placed may affect its performance and lifespan.

Future Outlook for SVCs

With increasing demands on power systems, and the rise in use of renewable energy sources, the future looks bright for SVCs. Their ability to stabilize voltage and improve electrical network efficiency will continue to make them essential components of modern power infrastructure.

SVCs in Renewable Energy Integration

The intermittent nature of renewable energy sources presents a significant challenge for maintaining grid stability. SVCs can help manage this by smoothing out power fluctuations, thus enabling a higher penetration of renewables into the grid without compromising reliability or performance.

For a detailed guide on selecting the right SVC, consider visiting the website of companies such as Siemens, a leading provider of power and automation technologies.

Difference Between Static and Dynamic VAR Compensators

When working with electrical power systems, the key difference between Static VAR Compensators (SVCs) and Dynamic VAR Compensators (DVCs) lies in their design, operation, and the nature of their response to voltage regulation tasks.

Overview of Dynamic VAR Compensator

A Dynamic VAR Compensator, often referred to as a Dynamic Voltage Restorer (DVR), is a device that provides rapid and precise adjustments to voltage levels in electrical power systems. Unlike SVCs, which use passive components, DVCs employ active elements like voltage-source converters.

Main Components of a Dynamic VAR Compensator

A DVC typically consists of:

- Voltage-Source Converters (VSCs): Convert DC to AC power and can generate or absorb reactive power dynamically.

- Energy Storage System: Provides the necessary power to the VSC for swift voltage adjustments.

- Control System: Manages the operation of the VSCs and the energy storage system for optimal performance.

Key Functions of a Dynamic VAR Compensator

Dynamic VAR Compensators focus on:

- Voltage Sag Compensation: Quickly restores voltage levels during sudden drops.

- Power Quality Improvement: Mitigates problems like voltage flicker and harmonics.

- Transient Stability: Enhances the grid’s ability to withstand and recover from disturbances.

Benefits of Using a Dynamic VAR Compensator

DVCs offer unique advantages, including:

- Ultra-Fast Response: Provides near-instantaneous voltage correction, important for sensitive industrial processes.

- Improved Grid Stability: Helps maintain stability during abrupt changes in load.

- Flexible Reactive Power Supply: Adapts quickly to varying reactive power demands in the grid.

Key Differences in Applications

While SVCs and DVCs both serve in voltage regulation and power quality improvement, their applications differ significantly:

| Feature | Static VAR Compensator (SVC) | Dynamic VAR Compensator (DVC) |

|---|---|---|

| Response Time | Milliseconds to Seconds | Microseconds to Milliseconds |

| Best For | Steady-state voltage control and power factor correction | Dynamic voltage restoration and transient stability |

| Components | Passive Elements (TCRs, TSCs) | Active Elements (VSCs, Energy Storage) |

| Example Application | Industrial plants with stable load requirements | Areas with frequent voltage sags and spikes |

Factors in Choosing Between SVC and DVC

When deciding between SVC and DVC, consider:

- Nature of Voltage Disturbances: For rapid and transient disturbances, DVCs are more suitable.

- Cost Considerations: DVCs generally have higher initial costs but may offer savings in reducing downtime and maintenance.

- Application Requirements: Evaluate whether steady-state control (SVC) or dynamic response (DVC) is more critical.

For more details on Dynamic VAR Compensators and their advantages, you can visit authoritative sources like ABB, which provides in-depth resources on these devices.

Expanding Upon Static VAR and Dynamic VAR Compensators

Integration in Smart Grids

Both Static VAR Compensators (SVCs) and Dynamic VAR Compensators (DVCs) play an important role in the functionality of smart grids. In a smart grid environment, the demand for real-time voltage regulation and reactive power control becomes even more important.

Applications in Smart Grids:

- Real-Time Monitoring: Both SVCs and DVCs can be integrated with advanced monitoring systems to provide continuous real-time data about grid conditions.

- Enhanced Scalability: These devices make it easier to adapt to changing load conditions, which are common in smart grid applications.

- Seamless Integration with Renewable Energy: Both SVCs and DVCs can be tailored to manage the intermittency of renewable energy sources effectively.

Cost and Maintenance

The cost and maintenance requirements differ significantly between SVCs and DVCs. Understanding these differences can guide decision-making processes:

| Cost Aspect | Static VAR Compensator (SVC) | Dynamic VAR Compensator (DVC) |

|---|---|---|

| Initial Cost | Moderate | High |

| Operational Cost | Low to Moderate | Moderate to High |

| Maintenance Needs | Low due to passive elements | High due to active components |

Thermal Management

Thermal management is another essential factor, especially in high-demand scenarios. Overheating can lead to device failure and increased maintenance costs.

- SVCs: Passive elements like thyristors generate less heat but require adequate cooling solutions to prevent thermal overload.

- DVCs: Active components like voltage-source converters generate more heat and necessitate advanced cooling systems to ensure stable operation.

Regulatory Compliance

In the evolving landscape of power systems, regulatory standards continue to influence the deployment of SVCs and DVCs.

- Grid Code Compliance: Both devices must comply with local and international grid codes regarding voltage stability and reactive power support.

- Environmental Regulations: Modern SVCs and DVCs are designed to minimize environmental impact, aligning with sustainability goals and regulations.

Future Trends in Voltage Compensation

Artificial Intelligence and Machine Learning

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into voltage compensation devices can revolutionize their efficiency and responsiveness.

- Predictive Maintenance: AI can predict and diagnose potential failures before they occur, reducing downtime and maintenance costs.

- Optimized Performance: ML algorithms can continually learn from operational data, fine-tuning the performance of SVCs and DVCs for greater efficiency.

Hybrid Solutions

Future power systems may increasingly adopt hybrid solutions that combine the benefits of both SVCs and DVCs.

- Flexibility: Hybrid systems can provide rapid response to transient conditions while also maintaining steady-state voltage control.

- Cost-Effectiveness: Utilizing both technologies can optimize cost by balancing initial investment with long-term operational efficiency.

Wireless and IoT Integration

The rise of the Internet of Things (IoT) offers new possibilities for remote monitoring and control of VAR compensators.

- Real-Time Data Access: IoT-enabled devices can provide real-time status and performance data accessible via any internet-connected device.

- Remote Diagnostics: Facilitates remote diagnostics and troubleshooting, reducing the need for on-site visits and maintenance.

For more advanced and specific details about integrating these technologies, companies like Schneider Electric offer extensive insights into the modern power management solutions.

Concluding Thoughts on Static and Dynamic VAR Compensators

In a world where the demand for stable and reliable power supply is on the rise, Static VAR Compensators (SVCs) and Dynamic VAR Compensators (DVCs) are playing an increasingly important role.

These devices, with their respective strengths in steady-state voltage control and dynamic response, are key in meeting the needs of different load conditions and power systems. Their use extends from industrial plants and electric utilities to the rapidly growing area of renewable energy sources.

The future of both SVCs and DVCs looks promising with advances like the integration of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) set to revolutionize their efficiency and responsiveness.

Frequently Asked Questions – FAQs

What are some key uses of Static VAR Compensators (SVCs)?

SVCs are used in voltage stabilization, power factor correction, and load balancing across electrical grids. They can also extend the lifespan of connected electrical equipment.

What differentiates Dynamic VAR Compensators (DVCs) from SVCs?

DVCs are designed to make rapid and precise adjustments to voltage levels in electrical power systems. This quick response time makes them ideal for handling rapid and transient disturbances, unlike the steady-state control provided by SVCs.

How do SVCs and DVCs support the integration of renewables in the grid?

Both SVCs and DVCs can manage the intermittency of renewable energy sources effectively, thereby allowing a higher penetration of renewables into the grid without compromising reliability or performance.

How will Artificial Intelligence (AI) and Machine Learning (ML) impact the future of SVCs and DVCs?

AI and ML can help predict potential failures, reduce downtime, and continually fine-tune the performance of SVCs and DVCs for greater efficiency.

What is a potential future trend in voltage compensation?

One likely trend is the adoption of hybrid systems that combine the benefits of both SVCs and DVCs. This offers flexibility and cost-effectiveness – providing rapid response to transient conditions while also maintaining steady-state voltage control.