A Quick Guide to Polymer Modified Mortar

Ever find yourself staring at a mortar mix, wondering how it could possibly withstand the pressures of the modern architectural era?

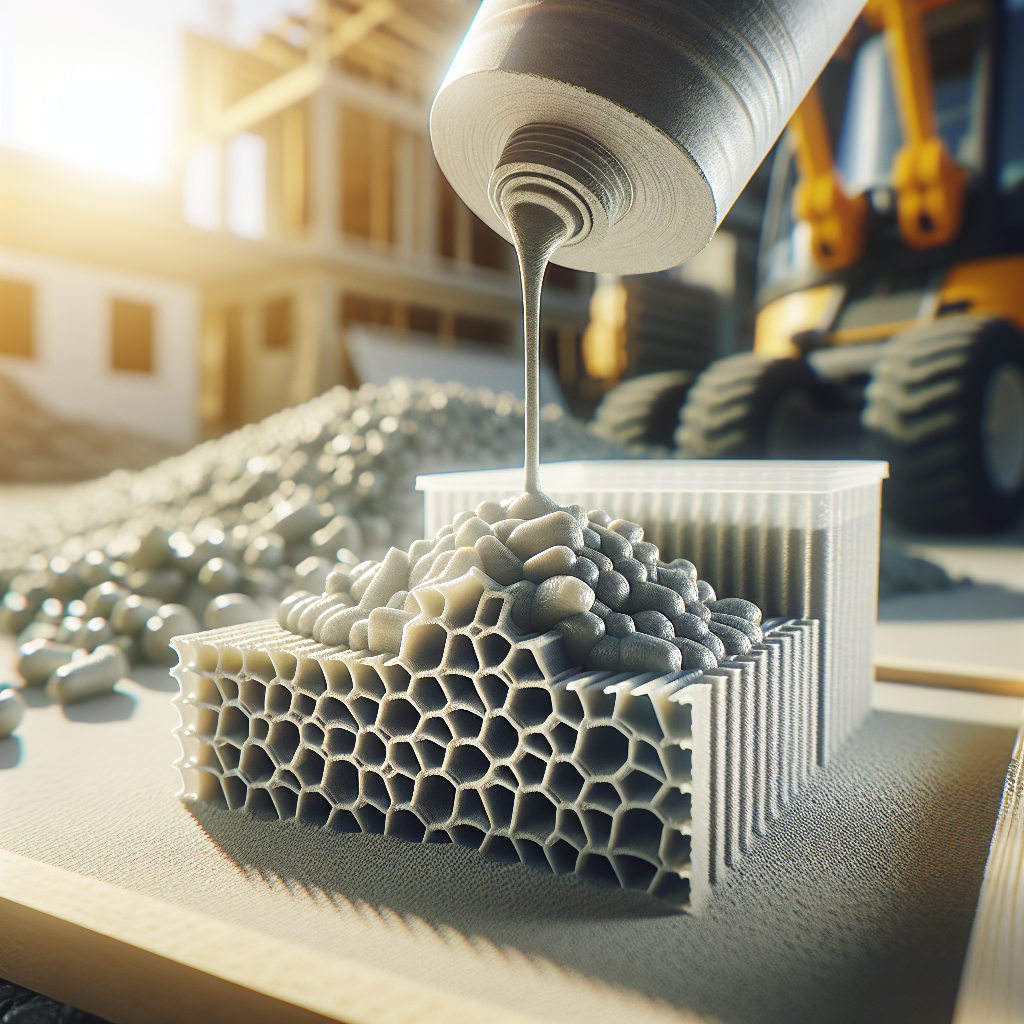

Well, that’s where Polymer Modified Mortar enters the scene. Did you know that when polymers are added to the traditional mix of mortar, it can significantly boost its performance?

In this blog post, we’re going to specifically discuss what polymer modified mortar is and why this is a game-changer in the construction industry. We’ll explore its key components, the plentiful benefits it brings to the table, and how it is commonly used in construction applications.

We’ll also touch upon its technical specifications, and finally, we’ll link you to some external resources for an even more comprehensive understanding of this versatile, durable product.

So, are you ready to learn more about polymer modified mortar?

Let’s get started.

Table of Contents

Understanding Polymer Modified Mortar in Construction

Definition of Polymer Modified Mortar

Polymer modified mortar is a type of mortar enhanced with polymer additives to improve its properties. These additives significantly improve the mortar’s flexibility, durability, and adhesion properties, making it a preferred choice for various construction applications.

Key Components

- Traditional Mortar Mix: Typically composed of cement, sand, and water.

- Polymer Additives: These can include latex, acrylic, and other synthetic materials.

Benefits of Using Polymer Modified Mortar

- Enhanced Flexibility: These mortars can accommodate better structural movements and stress without cracking.

- Improved Adhesion: They bond better to various surfaces, including concrete, brick, and even some non-porous materials.

- Increased Durability: More resistant to water, chemicals, and environmental wear and tear, leading to longer-lasting structures.

Applications in Construction

Common Uses

Polymer modified mortar is employed in a variety of construction applications, such as:

- Tiling and Flooring: Enhances the bond between tiles and substrates.

- Repair and Restoration: Ideal for fixing cracks and joints in different surfaces.

- Waterproofing: Often used in waterproof barriers due to its resistance to water penetration.

Special Requirements

To achieve the best results with polymer modified mortar, particular attention needs to be given to:

- Mixing: Follow manufacturer instructions closely to ensure proper proportions.

- Application: Ensure the surface is clean, dry, and free of contaminants for optimal adhesion.

- Curing: Proper curing times and conditions must be followed to achieve desired properties.

Technical Specifications

| Property | Traditional Mortar | Polymer Modified Mortar |

|---|---|---|

| Flexibility | Low | High |

| Adhesion | Moderate | Excellent |

| Durability | Standard | Enhanced |

| Water Resistance | Limited | High |

Understanding the role and advantages of polymer modified mortar in construction can help in selecting the right materials for specific needs. For further reading on the topic, please refer to this guide by Concrete Construction.

Polymer Additive for Mortar: Going Beyond Basic Compositions

Overview of Polymer Additives

Polymer additives, when incorporated into the base of a traditional mortar mix, alter the performance capabilities of the mortar, enhancing attributes such as strength, flexibility, and adhesion. This, in effect, results in a substance more resilient to the hardships of weather elements, chemical degradation, and mechanical stress.

Types of Polymer Additives

- Elastomers: This polymer additive, including substances like SBR and EVA, significantly enhances mortar’s flexibility and adhesion properties.

- Resins: Including substances like PVA and PMMA, these additives are known for enhancing mortar’s durability and resistance to chemical degradation.

- Thermoplastics: Additives like PVC and PE improve the flexibility of mortar, therefore increasing the tolerance to structural movement.

Essential Role of Polymer Additives in Mortar

Improving Functional Performance

The incorporation of polymer additives introduces engineered functionalities to the mortar beyond the capabilities of traditional cement-sand-water mixtures. These improved attributes include:

- Load Bearing: Enhanced tensile strength and compression resistance make the structure more enduring.

- Frost Resistance: Mortar with polymer additives are more tolerant to cold, delaying the freezing point of water within its composition.

- UV Resistance: Certain polymer additives can shield the mortar from harmful UV degradation, enhancing overall longevity.

Optimizing Behavior and Response

Polymer addiction not only improves the performance of the mortar but also slightly modifies the behavior and response of the mortar to environmental stimuli:

- Viscosity: Change in flow behavior upon the addition of polymers allows easier shaping and smoother application.

- Thermal Expansion: Polymers can reduce the rate of expansion and contraction due to temperature changes, thereby reducing the chance of cracking.

- Shrinkage: Polymer additives lessen the shrinkage rate, improving the stability of the structure.

Diving into Polymer Modified Mortar

Polymer additives for mortar extend the possibilities and deepen the complexities of mortar application in construction. To fully realize the potential of this novel technology, precise understanding, and meticulous application of these materials are required.

What is Polymer Cement Mortar Used For?

Primary Applications in Construction

Polymer cement mortar (PCM) is a versatile material used in numerous construction activities. Below are some key areas where PCM proves to be most effective.

Structural Strengthening

Polymer cement mortar is often used to restore and enhance the structural integrity of buildings and infrastructure. It increases the tensile strength of the repaired sections and provides a durable bond between the old and new materials.

- Bridge Repairs: Increases longevity and load-bearing capacity without extensive downtime.

- Column and Beam Strengthening: Enhances load distribution and provides added resilience to structural elements.

Flooring Solutions

PCM is a popular choice for industrial and commercial flooring due to its enhanced wear resistance and durability. It is perfect for applications demanding high performance and long-term reliability.

- Warehouse Floors: Withstands heavy machinery and traffic, reducing maintenance costs.

- Commercial Kitchens: Resistant to chemicals and impact, ideal for high-use areas.

Special Properties for Varied Applications

Polymer cement mortar can be tailored for specific conditions by adjusting the type and proportion of polymers used in the mix.

Waterproofing and Moisture Resistance

One of the standout features of PCM is its superior waterproofing capabilities.

- Swimming Pool Coatings: Prevents water seepage and resists chlorine and other pool chemicals.

- Basement Water Barriers: Provides a robust waterproof layer to prevent moisture ingress.

Resistance to Environmental Degradation

Polymer cement mortar’s resistance to environmental wear and tear makes it suitable for use in harsh conditions.

- Marine Structures: Protects against saltwater and marine life, enhancing the longevity of piers and docks.

- Industrial Zones: Resists chemical spills and high temperatures, making it ideal for heavy-duty industrial applications.

Considerations for Effective Use

To leverage the benefits of polymer cement mortar fully, several practices must be followed.

Proper Mixing Techniques

The performance of PCM is highly dependent on the quality of mixing. Following the manufacturer’s instructions ensures consistent results.

- Consistent Mixing Ratios: Ensures uniform properties in the final mix.

- Use of Mechanical Mixers: Provides thorough blending, reducing the likelihood of weak spots.

Surface Preparation

Proper preparation of the surface to which the polymer cement mortar is applied is crucial for optimal adhesion and performance.

- Cleaning: Remove any dust, grease, or other contaminants.

- Roughening: Create a suitable texture for better mechanical bond.

Is Polymer Modified Mortar the Same as Micro Concrete?

Comparing Polymer Modified Mortar and Micro Concrete

While both polymer modified mortar and micro concrete provide enhanced performance attributes for construction, they serve distinct roles and have unique compositions.

Below, we’ll break down the key aspects that differentiate these two materials.

Composition Differences

- Polymer Modified Mortar: As discussed, this type of mortar is made by adding polymers such as latex, acrylics, or other synthetic materials to traditional mortar (cement, sand, and water). These polymers improve flexibility, adhesion, and durability.

- Micro Concrete: Micro concrete typically consists of a blend of high-strength cement, very fine aggregates, and special admixtures. Unlike polymer modified mortar, micro concrete does not usually contain polymers. Instead, it includes materials designed to enhance flowability and strength.

Key Properties and Benefits

| Property | Polymer Modified Mortar | Micro Concrete |

|---|---|---|

| Flexibility | High | Moderate |

| Adhesion | Excellent | Good |

| Durability | Enhanced | High |

| Strength | Moderate | High |

| Flowability | Moderate | Excellent |

Typical Applications in Construction

Polymer Modified Mortar Applications

Polymer modified mortar is often used in situations where enhanced adhesion and flexibility are critical:

- Tiling: As an efficient adhesive for tiles in indoor and outdoor settings.

- Repair Work: Ideal for fixing cracks and joints due to its flexural capacity.

- Waterproofing: Effective in creating water-resistant barriers in bathrooms, kitchens, and basements.

Micro Concrete Applications

Micro concrete is typically employed in areas requiring high strength and excellent flowability:

- Structural Rehabilitation: Used in repairing and strengthening load-bearing structures such as beams, columns, and slabs due to its high compressive strength.

- Void Filling: Micro concrete’s excellent flow properties allow it to fill intricate voids and gaps in structural elements effectively.

- Underwater Applications: Because of its high flowability, micro concrete can be pumped into underwater structures with minimal disruption.

Special Considerations

When deciding whether to use polymer modified mortar or micro concrete, it is important to consider the specific requirements of your project:

- Structural Flexibility: If your application demands flexibility and the ability to handle structural movements, polymer modified mortar may be the better choice.

- High Strength Requirements: For applications demanding high compressive strength and comprehensive filling capabilities, micro concrete is typically the more suitable material.

For further details on material differences and application techniques, the resource page at Portland Cement Association provides in-depth information and guidance.

In Conclusion

Polymer modified mortar has emerged as a powerful tool in the construction industry, largely owing to its superior flexibility, adhesion, and durability compared to traditional mortar. The addition of polymer additives to the standard mortar matrix notably augments the material’s capacity to withstand environmental stressors, such as water infiltration and chemical exposure.

A notable benefit of using this technologically advanced mortar is its usage versatility; from flooring applications to repair and restoration projects, it caters to a wide array of construction needs. Correct mixing procedures and diligent attention to the application process can significantly enhance the end result, leading to robust structures that stand the test of time.

Whether it’s standing strong through inclement weather or withstanding heavy loads, polymer modified mortar has indeed fortified construction protocols, making structures safer and long-lasting.

Frequently Asked Questions – FAQs

What exactly is polymer modified mortar?

It is a type of mortar that is reinforced with unique polymer additives to enhance its properties substantially. This amplification majorly improves the mortar’s flexibility, durability, and adhesion to other surfaces, making it an advantageous choice for various construction applications.

What can polymer modified mortar be used for?

Generally, polymer modified mortar is suitable for a range of construction applications. Its high flexibility and bonding capabilities make it ideal for a range of purposes, such as tiling, flooring, repair and restoration work, and even waterproofing applications.

Why should I choose polymer modified mortar over traditional mortar?

Polymer modified mortar is more adept at handling movement and stress without cracking, and its ability to bond with varied types of surfaces is significantly superior to traditional mortar. It’s also highly resistant to water, chemicals, and general wear and tear, making it the choice for longer-lasting structures.

How to achieve the best results using polymer modified mortar?

To get the best out of the polymer modified mortar, the mixing should always be in accordance with the manufacturer’s instructions. The surface to which it will be applied should be clean, dry, and free of contaminants for optimal adhesion. Additionally, proper curing times and conditions should be followed to achieve the desired properties.