Introduction to Masonry Levels and Their Importance in Construction

Have you ever wondered how buildings and structures remain perfectly level during construction? It’s astonishing to know that a small tool called a masonry level plays a significant role.

In this blog post, we’re covering everything you need to know about masonry levels. We’ll start by defining a masonry level, understanding its key features, and exploring the different types available.

We’ll then show you how to effectively use a masonry level. You’ll learn when this instrument is necessary and discover useful tips for maintaining your tool for optimum condition and accuracy.

By the end of this post, you’ll be equipped with the fundamentals of masonry levels – ready to fully utilize them for your construction needs.

Ready? Let’s begin!

Table of Contents

Understanding Masonry Levels in Construction

What is a Masonry Level?

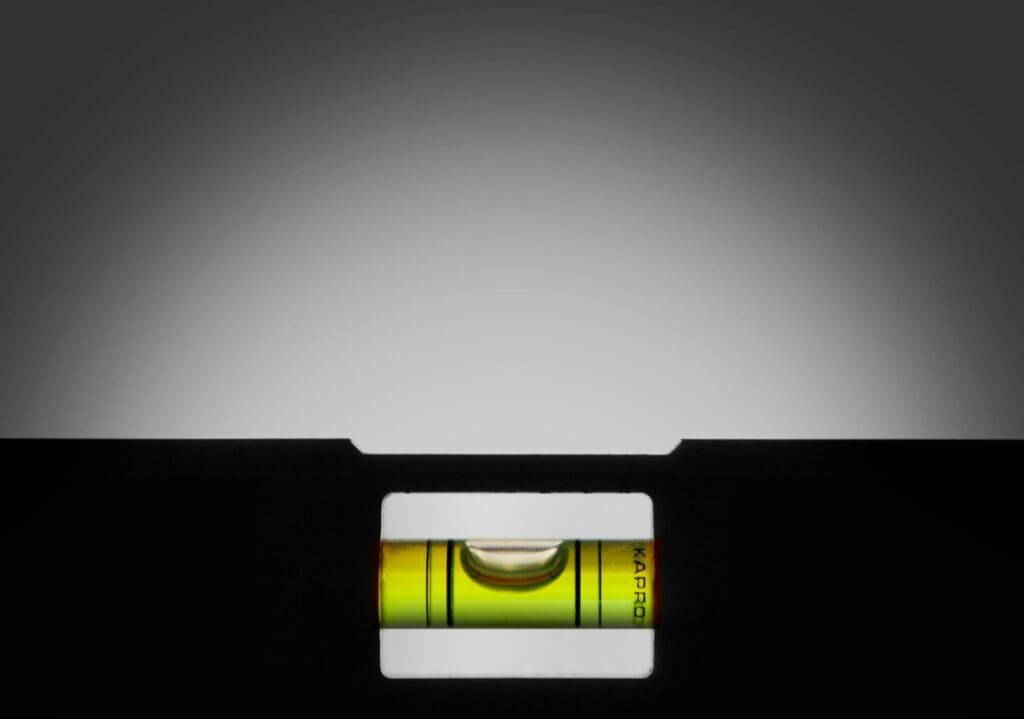

A masonry level is a specialized tool used in construction to ensure that surfaces, structures, or components are perfectly horizontal or vertical during the building process.

Key Features of a Masonry Level

- Material: Typically made of high-durability materials such as aluminum or wood.

- Accuracy: Includes bubble vials for precise leveling.

- Length: Usually ranges from 24 to 48 inches, but can vary based on the project’s requirements.

- Design: Often features a magnetic base to adhere to metal surfaces.

Types of Masonry Levels

Standard Masonry Level

- Basic model with bubble vials.

- Commonly used for general construction tasks.

Torpedo Level

- Smaller, more compact level.

- Used for tight spaces and smaller projects.

Digital Level

- Provides digital readouts for more precision.

- Features include backlighting and sound alerts.

How to Use a Masonry Level

Horizontal Leveling

- Place the level on the surface to be checked.

- Observe the bubble vial. The bubble should be centered between the lines for a level surface.

- Adjust the surface as needed.

Vertical Leveling

- Hold the level vertically against the surface.

- Again, the bubble should be centered to ensure vertical alignment.

When to Use a Masonry Level

- Laying Bricks and Blocks: Ensures each layer is level for overall stability.

- Installing Flooring: Makes sure the floor is even and secure.

- Framing Walls: Ensures the walls are plumb and straight.

For further reading on tools commonly used in masonry and construction, check out this helpful guide on The Home Depot website.

Using a Masonry Level for More Complex Projects

- Checking Angles: Some masonry levels come with multiple vials set at different angles (such as 45 degrees). Utilize these to ensure accurate measurements for complex structures like staircases or ramps.

- Direct Mounting: When working with large metal frameworks, use a masonry level with a magnetic base to attach directly to the metal, giving you hands-free leveling and increased stability.

- Continuous Leveling: For extended surfaces, employ a longer masonry level (48 inches or more) to ensure consistency over a larger span. For even greater accuracy, consider using a laser level in conjunction with your masonry level.

Maintaining Your Masonry Level

- Regular Cleaning: After each use, clean your masonry level to remove any debris. Dirt and grime can affect the accuracy of your readings.

- Calibration: Periodically check the calibration of the bubble vials. Some digital levels include self-calibration features, but manual levels may require professional calibration.

- Storage: Store in a dry place to avoid warping or damage. Consider using a protective case if transporting it frequently.

When to Use a Masonry Level

- Laying Bricks and Blocks: Ensures each layer is level for overall stability.

- Installing Flooring: Makes sure the floor is even and secure.

- Framing Walls: Ensures the walls are plumb and straight.

- Setting Up Beams and Joists: Essential for ensuring that structural elements are appropriately aligned and balanced.

For further reading on tools commonly used in masonry and construction, check out this helpful guide on The Home Depot website.

Key Advantages of Using Masonry Levels

While understanding what a masonry level is and how to use one is crucial, recognizing the benefits it brings to construction projects can further underscore their importance.

Ensures Precision and Accuracy

- Prevents Errors: Using a masonry level minimizes the chances of errors during construction, ensuring perfect alignment.

- Professional Quality: Achieving level surfaces and walls can significantly enhance the overall quality and appearance of the construction project.

Increases Efficiency

- Streamlines Workflow: With accurate leveling, builders can proceed with confidence, avoiding the need for frequent adjustments.

- Reduces Material Waste: Proper leveling reduces the need for corrections, thus saving materials and costs.

Choosing the Right Masonry Level for Your Project

Different projects may require different types of masonry levels. Here’s how to select the best one for your needs:

Project Size and Scope

- Small Projects: For minor tasks like hanging pictures or installing shelves, a torpedo level will suffice due to its compact size.

- Medium Projects: Standard masonry levels are ideal for tasks like constructing small walls or installing cabinetry.

- Large Projects: For extensive or professional projects, digital levels provide the precision necessary for large-scale construction.

Material and Environment

- Outdoor vs. Indoor: Aluminum levels are rust-resistant and better suited for outdoor use, whereas wood levels may be more suitable for indoor projects.

- Magnetic Base: If working predominantly with metal structures, a level with a magnetic base can provide added stability and convenience.

Advanced Techniques for Using Masonry Levels

These advanced methods can help you get the most out of your masonry level:

Setting a Benchmark

- Start by setting a benchmark level on your primary working surface. This serves as a reference point for all subsequent leveling tasks.

Using Multiple Levels

- For extensive areas, use multiple levels to check and recheck surfaces, ensuring no gradual deviations occur over longer distances.

Common Mistakes to Avoid

Being aware of potential pitfalls can help maintain the accuracy of your work:

Ignoring Calibration

- Ensure that your level is properly calibrated before each use. Failing to do so can result in misleading readings and compromised work quality.

Improper Storage

- Storing your levels improperly can lead to damage. Always keep them in a protected, dry place to maintain their integrity and accuracy.

Complementary Tools to Use with Masonry Levels

While masonry levels are essential, other tools can complement their use:

Laser Levels

- Laser levels: Provide a laser beam for long-distance leveling, which can be particularly useful for large construction sites.

Plumb Bobs

- Plumb Bobs: Useful for ensuring vertical alignment in conjunction with a masonry level.

Angle Finders

- Angle Finders: Assist in measuring and checking angles, helping to ensure precision for projects that require non-90-degree angles.

Difference Between Flatness and Levelness

Understanding flatness and levelness is crucial in construction to achieve precise results. Although they are related, they are distinct concepts.

Flatness

Flatness refers to making a surface even, without any dips or high spots. This is crucial in several construction tasks, such as laying a concrete slab or ensuring the evenness of a countertop.

- Measurement: Generally measured with a straightedge, feelers, or laser equipment to detect any deviations across a surface.

- Purpose: Ensures that materials or components laid on the surface sit evenly without wobbling.

- Applications: Flooring installation, countertop set-up, and any other tasks requiring a consistent surface.

Levelness

Levelness is about ensuring a surface is at a consistent height relative to the horizon. It is critical in structural integrity and alignment.

- Measurement: Achieved using tools like masonry levels, laser levels, and transit levels.

- Purpose: Ensures an entire surface is at the same elevation, crucial for stability and proper load distribution.

- Applications: Building foundations, framing walls, and mounting fixtures that demand exact horizontal or vertical alignment.

Comparative Analysis: Flatness vs. Levelness

| Aspect | Flatness | Levelness |

|---|---|---|

| Purpose | Ensure an even surface with no bumps or dips | Ensure a surface is uniformly aligned with the horizon |

| Measurement Tools | Straightedge, feelers, laser equipment | Masonry levels, laser levels, transit levels |

| Typical Applications | Flooring, countertops, steel plates | Foundations, walls, fixtures |

| Importance | Prevents wobbling and ensures even support | Ensures stability and proper load distribution |

Advanced Techniques for Ensuring Flatness and Levelness

Laser Equipment

Using laser equipment can help achieve both flatness and levelness over larger areas with more precision.

- Rotary Lasers: Used for leveling over vast surfaces, ensuring both flatness and horizontal alignment.

- Line Lasers: Useful for smaller tasks like tiling or framing, ensuring straight, level lines.

Shim and Grind Techniques

For flatness, especially in renovation work, using shims can help adjust surfaces. Grinding down high spots also ensures a flatter result.

- Shimming: Adding thin pieces of material to low spots to level out a surface.

- Grinding: Removing high points for a more even surface, often used in concrete work.

For further reading on tools commonly used in masonry and construction, check out this helpful guide on The Home Depot website.

In Conclusion

In the construction world, masonry levels play a significant role in ensuring that surfaces and structures are perfectly horizontal or vertical.

They come in various designs, lengths, and types including standard masonry levels, torpedo levels, and digital levels, each catering to different project requirements. Usage of these tools isn’t confined to a single process, they find their applications in laying bricks, installing flooring, and framing walls.

Accuracy of your project can be ascertained by masonry levels only when they are maintained properly and calibrated regularly.

The article also effectively differentiates between two important concepts in construction, ‘flatness’ and ‘levelness’. Both critical but distinct, these play an imperative role in ensuring precision in construction tasks.

At the end of the day, understanding and implementing the use of these tools and concepts in your construction project can significantly raise the efficiency and quality of your work.

Frequently Asked Questions – FAQs

What’s the purpose of a masonry level in construction?

A masonry level is used to ensure that surfaces, structures, or components are perfectly horizontal or vertical during the construction process.

Can masonry levels be used for all construction tasks?

Please refer to the ‘Types of Masonry Levels’ section in the article for specific uses of each type of level. However, generally, they are used across various tasks in construction including, but not limited to, laying bricks, installing flooring, and framing walls.

How do we differentiate between ‘levelness’ and ‘flatness’?

While both are critical in construction, ‘flatness’ deals with the evenness of the surface without dips or high spots. ‘Levelness’, on the other hand, ensures that all points of the surface are at a consistent height relative to the horizon. Levelness is key in maintaining structural integrity and alignment.

What is the importance of maintaining a masonry level?

Maintaining your masonry level is crucial as the accumulation of dirt and grime can affect the accuracy of readings. Regular cleaning, proper calibration, and careful storage in a dry place all contribute to the consistent functionality of the masonry level.