Introduction To Perpends In Masonry

Ever wondered how the bricks in a wall stay perfectly aligned and stable?

The secret lies in something as simple as a “perpend” (sometimes called a “head joint”).

In this blog post, we’ll break down what a perpend is, its importance in masonry, and even compare it with other construction terms like bed joints and laps.

We’ll also discuss good practices and common problems associated with perpends to ensure your masonry work stands the test of time.

By the end of this article, you’ll have a solid understanding of this often-overlooked, yet essential, element of construction.

Table of Contents

Understanding the Construction Term: Perpend

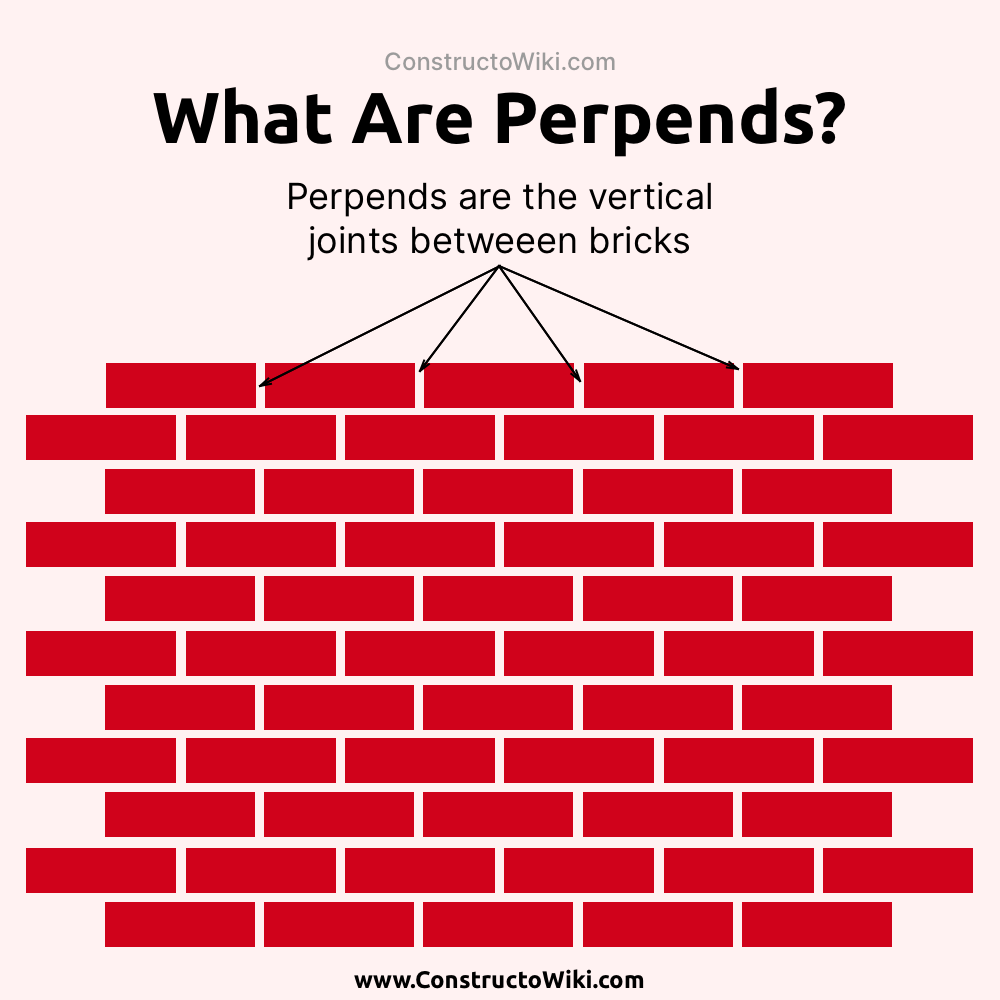

Definition of Perpend

A perpend is a vertical joint between bricks in masonry construction. It is essential in ensuring the structural integrity of walls and even distribution of loads.

Where Perpends Are Found

Perpends are found in:

- Brick Walls

- Stone Masonry

- Concrete Block Walls

Importance of Proper Perpends

- Structural Integrity: Ensures that vertical loads are properly transferred down the wall.

- Alignment: Maintains straight and level lines in wall construction.

- Aesthetic Appeal: Contributes to the visual symmetry of the wall.

Spacing of Perpends

The spacing and alignment of perpends are essential for both function and aesthetics.

| Type of Masonry | Perpend Spacing |

|---|---|

| Brick | A typical spacing is every 4 inches |

| Concrete Blocks | A typical spacing is every 8 inches |

| Stone | Varies depending on the size of the stone |

Good Practices for Perpends

- Consistency: Ensure perpends are consistently spaced for uniformity.

- Mortar Joints: Fill vertical joints thoroughly with mortar to avoid weak spots.

- Weather Protection: Adequate mortar joints help protect against water ingress.

Common Problems with Perpends

- Cracking: Improper alignment can lead to cracking along the joints.

- Water Ingress: Poorly filled perpends can allow water penetration, leading to damp walls.

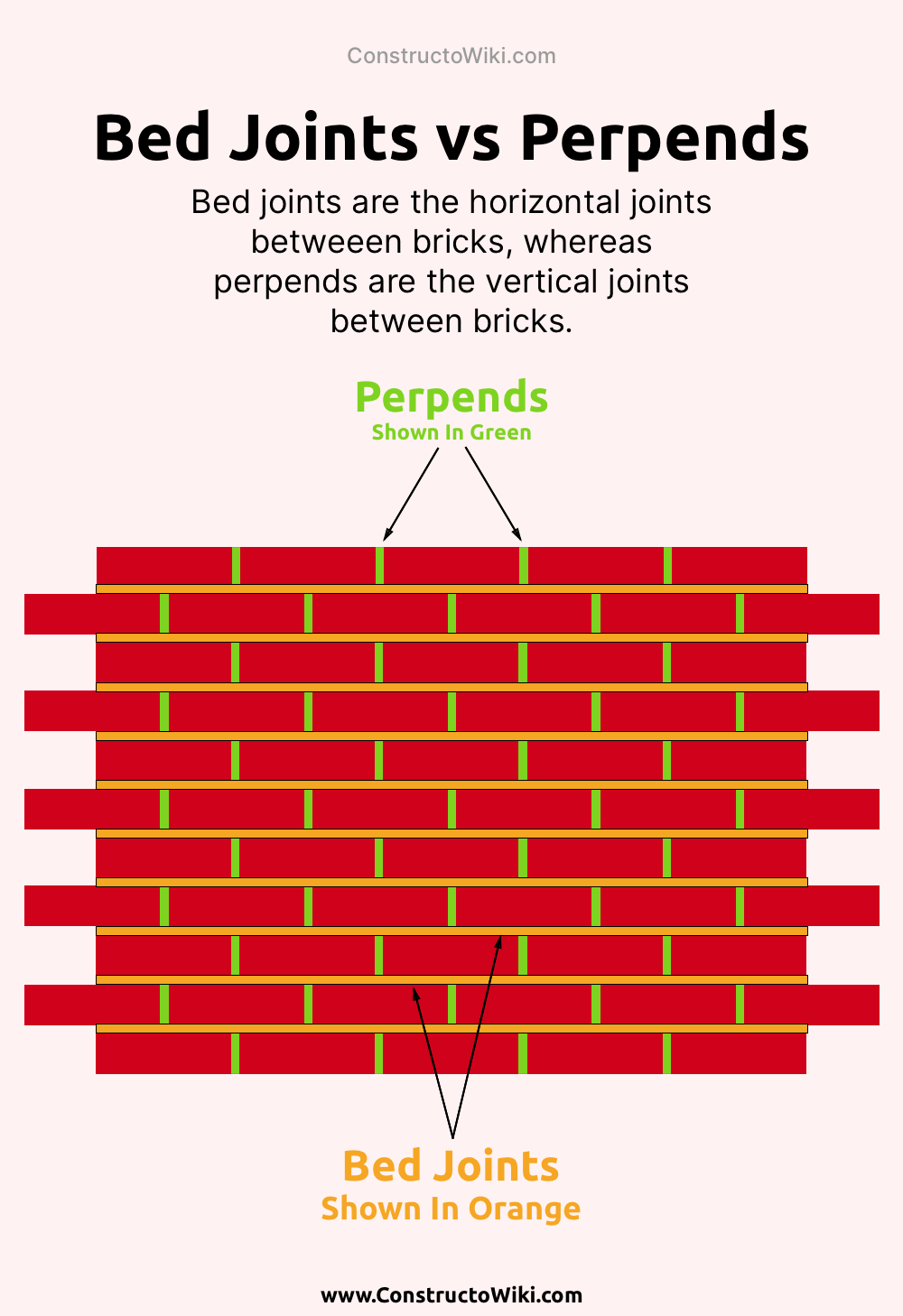

The Differences Between Perpends and Bed Joints

Definition of Bed Joint

A bed joint is the horizontal mortar joint between two bricks or stones. Bed joints ensure that the horizontal layers in masonry construction remain level and evenly spaced.

Where Bed Joints Are Found

Bed joints are found in:

- Brick Walls

- Stone Masonry

- Concrete Block Walls

Importance of Proper Bed Joints

- Level Surface: Ensures a level base for each subsequent layer of bricks.

- Even Load Distribution: Distributes the weight of the wall evenly across the lower layers.

- Structural Bond: Enhances the overall stability of the structure by tying bricks together horizontally.

Spacing and Thickness of Bed Joints

Bed joints typically have specific thickness requirements to maintain structural integrity.

| Type of Masonry | Bed Joint Thickness |

|---|---|

| Brick | Typically 3/8 inch to 1/2 inch |

| Concrete Blocks | Roughly 3/8 inch to 5/8 inch |

| Stone | Varies depending on the type and size of the stone |

Good Practices for Bed Joints

- Leveling: Ensure bed joints are level to maintain the horizontal uniformity of the wall.

- Uniform Thickness: Keep bed joints at a consistent thickness to aid in load distribution.

- Proper Mortar Use: Use the appropriate type and amount of mortar to fill joints completely, avoiding voids that can weaken the structure.

Common Problems with Bed Joints

- Uneven Joints: Uneven bed joints can lead to sloping walls and compromised structural integrity.

- Differential Settling: If bed joints aren’t filled properly, different parts of the wall may settle unevenly.

- Mortar Deterioration: Poor-quality mortar or inadequate mixing can lead to the mortar crumbling and weakening over time.

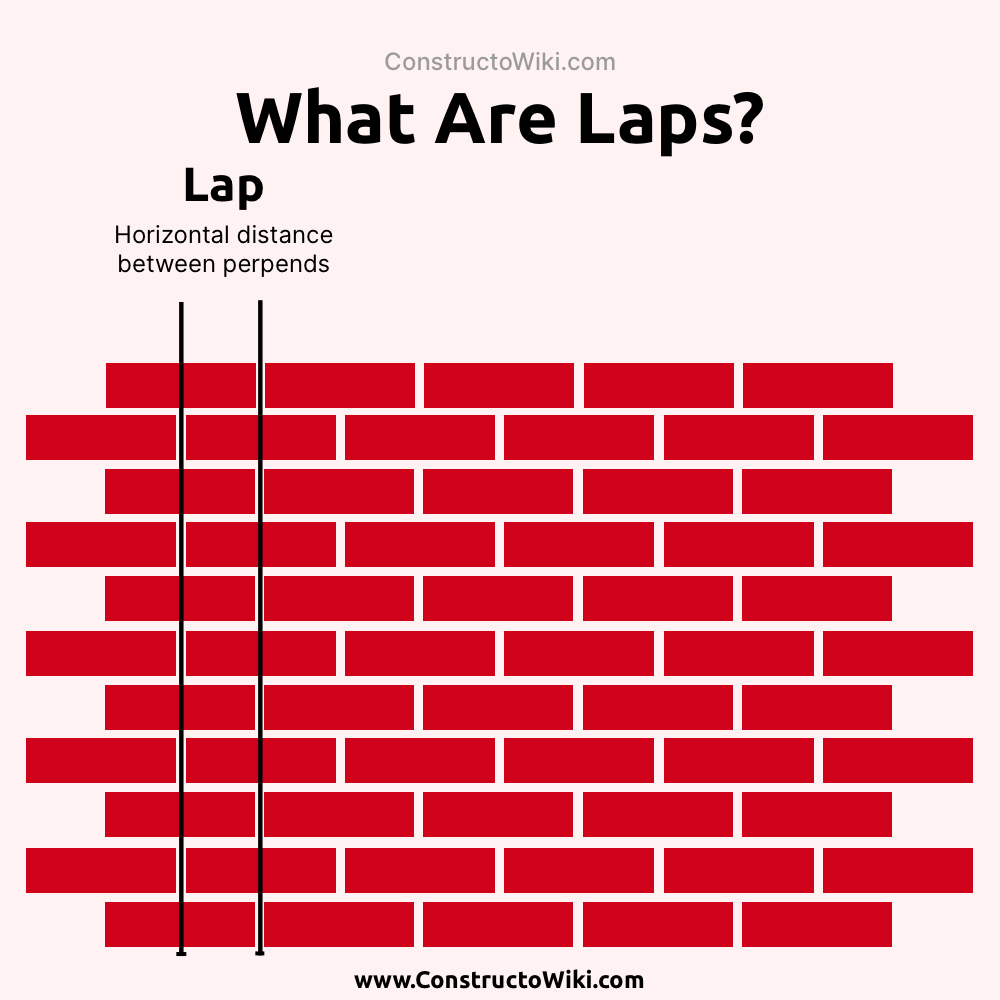

Understanding the Brickwork Term: Lap

Definition of Lap

A lap in construction refers to the overlapping of materials, often to ensure stability and continuity. Laps are commonly used in various construction elements – not only brickwork –such as roofing, reinforcing steel, and cladding.

Where Laps Are Found

Laps are frequently found in:

- Brickwork

- Roofing Shingles

- Reinforced Concrete Structures

- Wall Cladding

- Sheet Metal Work

Importance of Proper Laps

- Waterproofing: Ensures that water does not penetrate through joints, especially in roofing.

- Load Transfer: In reinforced concrete, laps help evenly distribute loads across joints.

- Structural Bond: Provides continuity of material, enhancing strength and stability.

Types of Laps

Different types of laps are used depending on the context and material.

| Type of Lap | Description |

|---|---|

| End Lap | Overlapping at the ends of the materials, often seen in steel reinforcement bars. |

| Side Lap | Overlapping along the sides, commonly used in sheet metal and roofing shingles. |

| Cover Lap | Overlapping where one material entirely covers another, typically used in waterproofing layers. |

Good Practices for Laps

- Correct Measurement: Ensure that the overlap length meets design specifications to maintain structural integrity.

- Material Compatibility: Use compatible materials to avoid potential issues like galvanic corrosion in metal works.

- Proper Fastening: Securely fasten lapping materials to prevent dislocation and ensure effective load transfer.

Common Problems with Laps

- Insufficient Lap Length: Short laps can lead to weak joints and potential structural failure.

- Water Leakage: Poorly executed laps can allow water to seep through, causing damage over time.

- Corrosion: Incompatible materials can corrode at the lap joint, leading to material degradation.

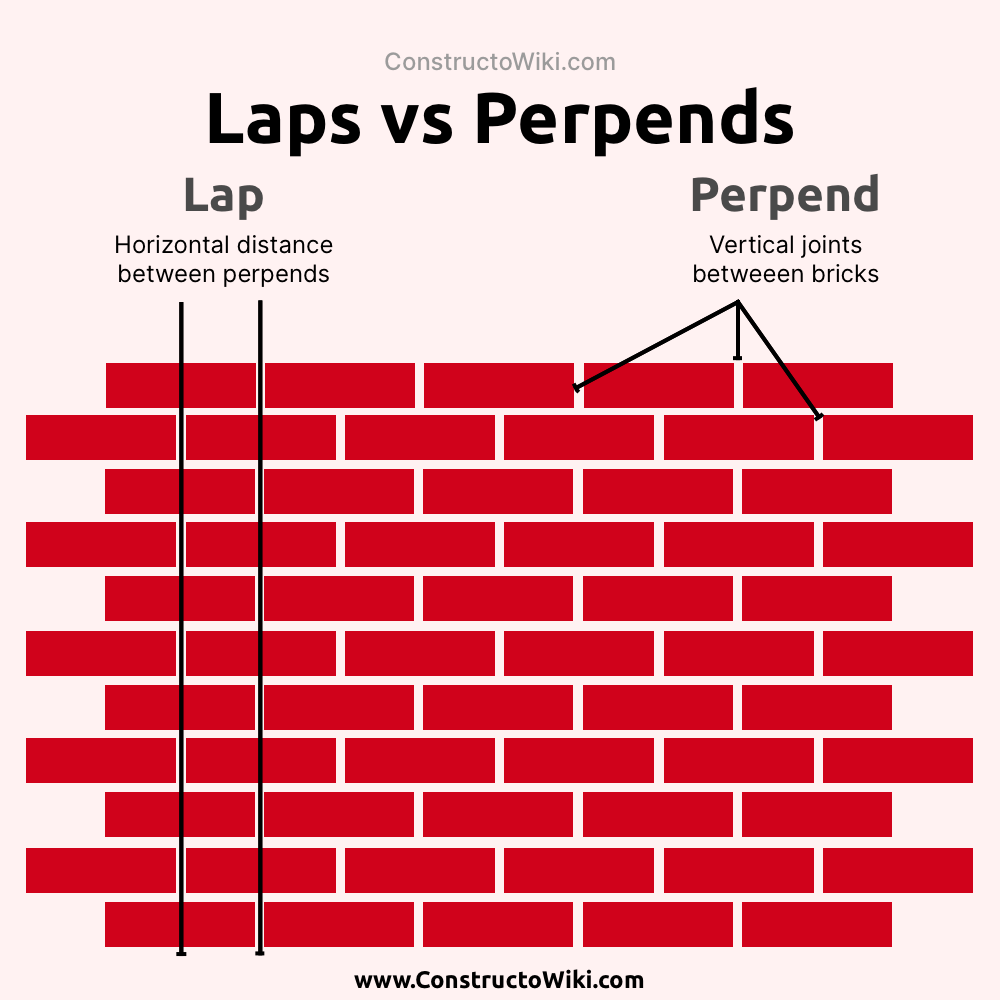

The Differences Between Perpends and Laps

Purpose

- Perpends: Vertical joints in masonry that help maintain structural integrity and aesthetic alignment.

- Laps: Overlapping of materials to ensure seamless load transfer, waterproofing, and material continuity.

Application

- Perpends: Found primarily in masonry work such as brick and stone walls.

- Laps: Used across various construction elements like brickwork, steel reinforcements, roofing shingles, and wall cladding.

Critical Aspects

- Perpends: Spacing and alignment are vital for load distribution and aesthetic purposes.

- Laps: Correct overlap length and proper fastening are essential to ensure durability and functionality.

Understanding these key differences and their applications can help ensure the success of construction projects by focusing on the specific requirements and best practices for each term. For more detailed insights into proper mortar joints, refer to this guide on pointing mortar joints.

What Are Open Perpends?

Definition of Open Perpends (“Weep Holes”)

Open perpends are vertical joints in masonry that are deliberately left unfilled or partially filled with mortar. These open spaces serve specific functional purposes in construction beyond merely holding the bricks or blocks together.

Where Open Perpends Are Used

Open perpends can be found in various masonry structures, including:

- Brick Veneer Walls

- Stone Masonry Walls

- Concrete Block Walls with Cavity

Importance of Open Perpends

- Ventilation: Facilitate airflow through the wall cavity, helping to dry out moisture and reduce mold growth.

- Drainage: Allow any water that penetrates the masonry to drain out, protecting the structural integrity of the wall. They are colloquially referred to as “weep holes.”

- Pressure Equalization: Help in equalizing pressure within the cavity to prevent water ingress, especially in high wind areas.

Good Practices for Open Perpends

- Consistent Spacing: To ensure uniform airflow and drainage, open perpends should be consistently spaced, typically every fourth or fifth vertical joint.

- Proper Placement: Place open perpends towards the bottom of the wall to facilitate effective drainage.

- Maintenance: Regularly inspect open perpends to ensure they are not blocked by debris or mortar droppings.

Common Problems with Open Perpends

- Blockages: Debris or mortar droppings can block open perpends, negating their benefits of drainage and ventilation.

- Inconsistent Spacing: Unevenly spaced open perpends can lead to poor ventilation and drainage inefficiencies.

Advantages of Open Perpends in Modern Construction

Enhanced Moisture Management

Open perpends play an essential role in modern masonry construction for managing moisture within wall cavities. They allow water that has penetrated the exterior veneer to escape, preventing buildup and potential water damage to the internal structure.

Improved Air Circulation

By facilitating airflow within the wall cavity, open perpends help in drying out moisture, reducing the risk of mold and mildew, which can compromise both the structural integrity and indoor air quality.

Regulatory Compliance

In many regions, building codes necessitate the use of open perpends in cavity walls to ensure adequate moisture management and ventilation, thus making them essential for compliance with local regulations.

Key Takeaways: Perpends, Bed Joints, and Laps in Masonry

Understanding the roles of perpends, bed joints, and laps in construction is essential for ensuring structural integrity, efficient load distribution, and aesthetic appeal. These elements, when properly executed, contribute to the long-term durability and visual symmetry of masonry structures.

Practicing consistent spacing, appropriate mortar use, and correct overlapping techniques can prevent common issues such as cracking, water ingress, and structural instability.

Frequently Asked Questions – FAQs

What is a perpend?

A perpend is a vertical joint between bricks in masonry construction, vital for structural integrity and load distribution.

Why is proper spacing of bed joints important?

Proper spacing of bed joints ensures level surfaces, even load distribution, and maintains the stability and aesthetics of the structure.

What are common issues with laps in construction?

Common issues with laps include insufficient lap length, water leakage, and material corrosion, which can lead to structural failure.

How do open perpends benefit masonry walls?

Open perpends facilitate ventilation, manage moisture, and help drain water from wall cavities, preventing mold and structural damage.

What are good practices for ensuring effective perpends?

Ensure consistent spacing, fill joints with mortar thoroughly, and protect joints from water ingress to maintain structural strength.