Introduction To Bed Joints in Masonry

Have you ever wondered why some masonry structures stand the test of time while others falter? It often comes down to the details, like bed joints.

By understanding bed joints, you can appreciate their vital role in ensuring masonry’s stability and durability.

In this article, we’ll define bed joints, explore their key characteristics and functions, and discuss their importance in construction. We’ll also touch on common issues, types of mortar used, necessary construction techniques, and how to maintain bed joints.

This will give you a comprehensive understanding of these critical components in masonry construction.

Table of Contents

What Is The Function of Bed Joints?

Definition and Purpose

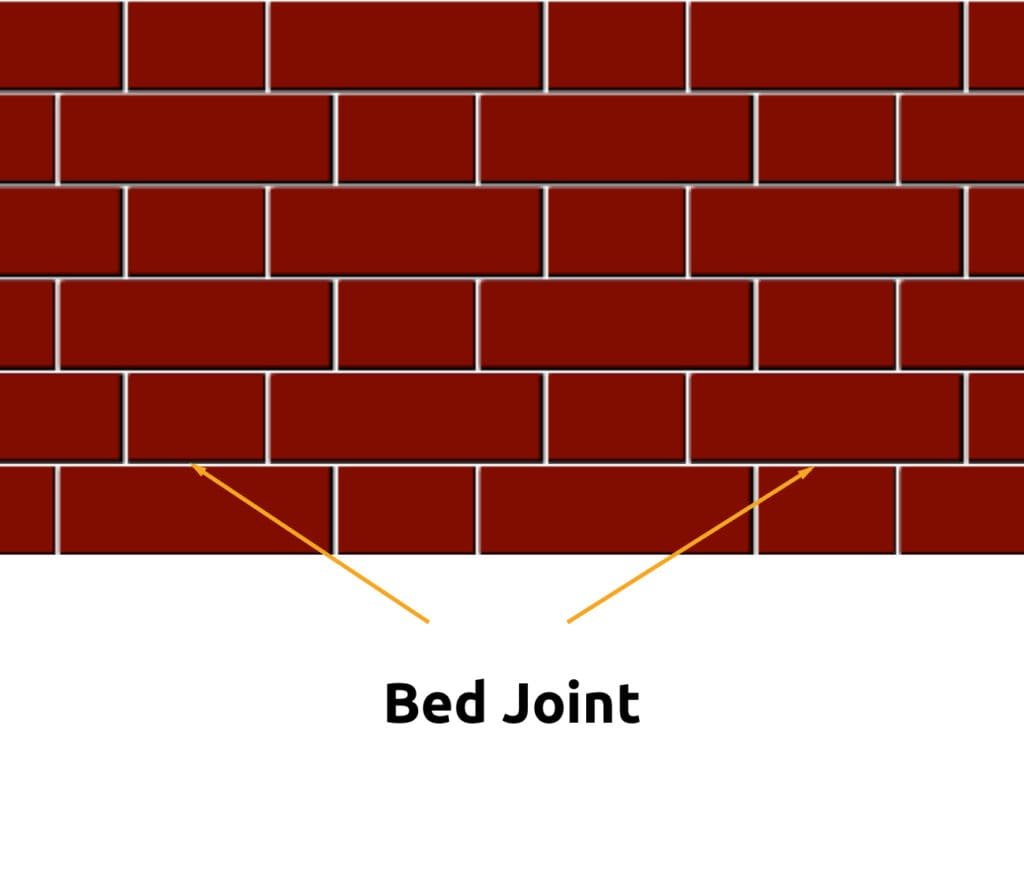

A bed joint in masonry refers to the horizontal layer of mortar on which masonry units, such as bricks or stones, are laid. It acts as a binding agent between layers, ensuring the stability, alignment, and strength of the overall structure.

Key Characteristics

Bed joints are essential for the integrity of masonry structures, and understanding their characteristics is critical for quality construction:

- Thickness: Typically ranges from 3/8 inch to 1/2 inch.

- Composition: Made of a mix of cement, sand, and water (mortar).

- Location: Found between each course of masonry units.

Functions of Bed Joints

Bed joints serve several important functions in masonry construction:

- Structural Support: Distribute loads uniformly across the masonry units.

- Alignment: Help in aligning the masonry units horizontally.

- Sealing: Prevents water infiltration and enhances the weather resistance of the wall.

Importance in Construction

The quality of bed joints directly impacts the durability and stability of masonry structures. Properly executed bed joints can prevent structural issues such as cracking and misalignment.

Common Issues

Masonry work can face several issues if bed joints are not properly managed:

- Uneven Thickness: Can lead to weak spots within the wall.

- Improper Mortar Mix: May compromise the bond between masonry units.

- Inadequate Curing: Insufficient curing time can weaken the mortar.

Mortar Types For Bed Joints in Masonry

Types of Mortar for Bed Joints

Different types of mortar can be used for bed joints, each offering unique properties suited to various construction needs. Here’s a quick overview:

| Type of Mortar | Key Characteristics |

|---|---|

| Type M Mortar | High compressive strength, suitable for below-grade applications like foundations. |

| Type S Mortar | Moderate compressive strength, good for exterior walls and masonry subjected to severe weather or soil pressure. |

| Type N Mortar | General-purpose, suitable for above-grade walls and chimneys. |

| Type O Mortar | Low compressive strength, used for interior, non-load-bearing walls or historic restoration work. |

Construction Techniques

To ensure the bed joints perform optimally, applying the correct techniques during construction is vital.

- Consistent Thickness: Use a trowel to maintain even thickness across all bed joints, as irregularity can lead to weak spots.

- Proper Compaction: Ensuring that mortar is properly compacted eliminates air pockets, increasing the joint’s strength and durability.

- Correct Moisture Content: The masonry units should be slightly damp before laying to ensure proper adhesion without too much water absorption.

Role of Bed Joints in Thermal Movement

Masonry structures expand and contract due to temperature changes. Bed joints play a crucial role in accommodating these movements.

- Expansion: Bed joints can absorb some of the expansion stress, provided they have the appropriate elasticity.

- Contraction: Similarly, as the material contracts, well-made bed joints help in managing the stress to prevent cracks.

Maintenance of Bed Joints

Proper maintenance of bed joints is essential for the long-term health of masonry structures.

- Repointing: Over time, mortar in bed joints can erode and should be replaced to maintain the structural integrity. This process is known as repointing.

- Regular Inspection: Conduct periodic inspections to detect and address issues before they become significant problems.

- Moisture Control: Implementing proper moisture management systems like weep holes can prevent water ingress and the related issues.

Basic Terminology in Masonry Construction

Types of Masonry Units

Masonry construction involves the use of assorted materials called masonry units. Here’s a quick guide:

- Bricks: The most common masonry unit, typically made from clay and can be used for both structural and decorative purposes.

- Concrete Blocks: Larger than bricks and made from concrete, these blocks provide structural strength and are often used in load-bearing walls.

- Stones: Natural building materials that include variations like granite, limestone, and marble. Used for their aesthetic appeal and durability.

- Glass Blocks: Mainly used for decorative features and allowing light penetration while ensuring privacy.

Mortar Joints

Apart from bed joints, other types of mortar joints play roles in masonry construction:

- Head Joints: Vertical joints between masonry units that help bind the units together horizontally.

- Collar Joints: The vertical joints between two wythes (layers) of masonry. These are rarely used alone and need to be filled to improve stability.

- Control Joints: Intentional gaps included to absorb movement caused by expansion or contraction of masonry units, thus preventing cracks.

Bond Patterns

The way masonry units are arranged is known as a bond pattern. Here are some common patterns:

- Running Bond: The simplest pattern, where each brick is offset horizontally by half its length in each row.

- Stack Bond: Bricks are directly aligned above and below each other; used more for aesthetics as it has less structural strength.

- English Bond: Alternates rows of stretchers (lengthwise bricks) and headers (short side of the brick facing out), offering strong lateral strength.

- Flemish Bond: Each row is alternated with stretchers and headers, providing a decorative pattern and strong bonding.

Tools for Masonry Work

Several tools are essential for proper masonry construction:

- Trowel: Used for spreading mortar. The shape can vary depending on the type of work.

- Brick Hammer: Useful for cutting bricks to size. One side is flat for striking, while the other side is chiseled.

- Jointer: Used to create smooth, concave, or v-shaped indentations in mortar joints, improving water resistance and aesthetics.

- Level: Ensures that both horizontal and vertical alignments are precise. Crucial for the stability of the wall.

Thermal and Moisture Management

Managing thermal and moisture movement within masonry is key for longevity and stability:

- Weep Holes: Small openings that allow moisture to escape from walls, preventing water accumulation and potential damage.

- Insulation: Adding thermal insulation materials behind masonry walls helps in maintaining interior temperature and energy efficiency.

- Expansion Joints: These joints accommodate thermal expansion and contraction, reducing the risk of cracking in large structures.

For further information on various aspects of masonry construction, including tools and techniques, you can visit Archtoolbox, a reliable source for construction professionals.

Putting To Bed Our Article About Bed Joints in Masonry

In conclusion, the role of bed joints in masonry is integral to the overall stability, durability, and longevity of masonry structures.

Proper thickness, composition, and construction techniques of bed joints ensure that masonry units remain well-aligned, case crack-resilient, and have their loads uniformly distributed.

Different types of mortar can be used depending on the specific requirements of each construction project, while maintenance practices like repointing are essential for preserving structural integrity.

Adherence to best practices in bed joint construction and maintenance significantly contributes to preventing common issues such as uneven thickness, improper mortar mix, and inadequate curing, ensuring the robustness of masonry work.

Frequently Asked Questions – FAQs

What is a bed joint in masonry?

A bed joint is the horizontal layer of mortar on which masonry units, like bricks or stones, are laid.

What is the typical thickness of a bed joint?

The thickness typically ranges from 3/8 inch to 1/2 inch.

Why are bed joints important?

Bed joints are essential for structural support, alignment, and preventing water infiltration in masonry structures.

What are common issues with bed joints?

Common issues include uneven thickness, improper mortar mix, and inadequate curing time.

How can I maintain bed joints?

Regular inspections, repointing, and moisture control are key to maintaining bed joints.

What types of mortar are used for bed joints?

Types of mortar include Type M, Type S, Type N, and Type O, each suited to different construction needs.