Understanding ‘Starved Cell’ in Construction Batteries

“An ounce of prevention is worth a pound of cure.” — Benjamin Franklin.

This quote couldn’t be more true when it comes to managing batteries in the construction industry.

Have you ever wondered why your construction equipment batteries die faster than expected? Or why there’s always some maintenance involved?

In this blog post, we’ll explore the fascinating world of starved cell batteries, also known as valve-regulated lead-acid (VRLA) batteries, and discover how they are game-changers for the construction industry. We’ll cover what starved cell batteries are, their key characteristics, how they work, and their applications in construction.

We’ll also examine how they differ from traditional lead-acid batteries, including their construction, operational characteristics, and environmental impact.

Finally, we’ll discuss the benefits and potential drawbacks of using starved cell batteries and offer tips on extending their lifespan.

Let’s explore how these advanced batteries can help improve efficiency and safety in your construction projects.

Table of Contents

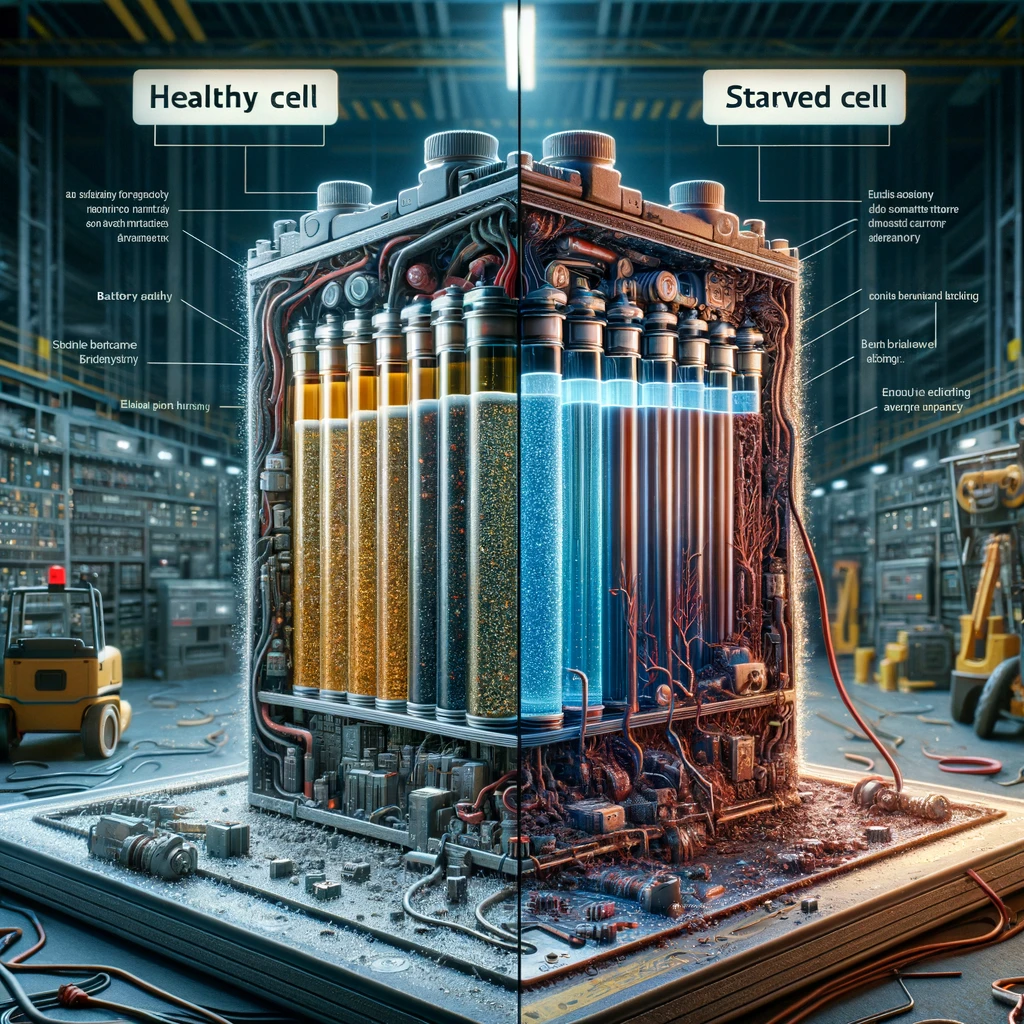

Introduction to Starved Cell Batteries

Starved cell batteries, often referred to as valve-regulated lead-acid (VRLA) batteries, are widely used in various construction applications due to their efficiency and safety features.

Key Characteristics of Starved Cell Batteries

- Maintenance-Free: Unlike traditional batteries, starved cells do not need regular topping up with water.

- Sealed Design: These batteries are sealed, preventing leaks and making them safer for use in different environments.

- Longer Lifespan: The design leads to a longer operational lifespan under proper conditions.

How Starved Cell Batteries Work

Starved cell batteries operate by using a reduced amount of electrolyte, which is absorbed by a fiberglass mat inside the battery. This allows for the recombination of gases produced during the electrochemical reaction, minimizing the need for external ventilation.

Key Components

- Electrolyte: A limited amount of electrolyte absorbed by a fiberglass mat.

- Fiberglass Mat: Absorbs the electrolyte, reducing the need for maintenance.

- Sealed Valve: Helps regulate internal pressure and minimize gas release.

Performance Table

| Feature | Starved Cell Battery | Traditional Lead-Acid Battery |

|---|---|---|

| Maintenance | Low to none | High, requires water topping |

| Safety | High, sealed design | Moderate, risk of leaks |

| Lifespan | Longer | Shorter |

Applications in Construction

Starved cell batteries are ideal for various construction equipment and backup power systems due to their durability and low maintenance needs. They are often found in:

- Scissor lifts and aerial work platforms

- Backup power for critical systems

- Portable power tools

For more detailed information on starved cell batteries, check out this comprehensive guide on Exploratorium.

How Starved Cell Batteries Differ from Typical Lead-Acid Batteries

Construction and Design Differences

Starved cell batteries, or valve-regulated lead-acid (VRLA) batteries, feature a fundamentally different design compared to traditional lead-acid batteries.

- Electrolyte Management: Starved cell batteries use an absorbed glass mat (AGM) or gel to immobilize the electrolyte, unlike typical lead-acid batteries that have a free-flowing liquid electrolyte.

- Construction: The physical structure of starved cell batteries is usually more compact, making them easier to fit into various equipment and enclosures.

Operational Characteristics

The operational aspects of starved cell batteries significantly differ from traditional lead-acid equivalents.

- Efficiency: Starved cell batteries generally offer higher efficiency, providing more usable power due to lower internal resistance.

- Temperature Tolerance: They tend to perform better in a wider range of temperatures, especially under extreme conditions, compared to typical lead-acid batteries.

Charging Process

The charging requirements and practices for starved cell batteries differ markedly from those of traditional lead-acid batteries.

- Charging Rates: Starved cell batteries typically support quicker charging cycles, allowing for faster equipment turnaround times, which is especially beneficial in high-demand construction environments.

- Overcharge Protection: Due to their sealed design and valve regulation, these batteries are better protected against overcharging, reducing the risk of damage.

Environmental Impact

The environmental considerations also show some differences.

- Spillage Risk: The sealed design of starved cell batteries virtually eliminates the risk of acid spillage, making them more environmentally safe.

- Recycling: Both starved cell and traditional lead-acid batteries are recyclable, but the ease of handling sealed units makes the recycling process somewhat simpler.

Use Cases Outside Construction

Beyond construction sites, starved cell batteries are also widely used in various other sectors due to their practical advantages.

- Telecommunications: They provide reliable backup power for cellular towers and other communication equipment.

- Uninterruptible Power Supplies (UPS): These batteries are often found in UPS systems to ensure continuous power for computers, data centers, and critical infrastructures.

- Marine Applications: Their sealed design makes them suitable for use in marine environments, where exposure to water and vibrations are key considerations.

For more nuanced details about starved cell and traditional lead-acid batteries, you can explore this article from the Exploratorium.

Potential Drawbacks and Benefits of Using a Starved Cell Battery

Benefits of Starved Cell Batteries

Starved cell batteries, also known as valve-regulated lead-acid (VRLA) batteries, bring a range of advantages to the table, especially for construction and other demanding applications.

- Maintenance-Free: One of the biggest benefits is the maintenance-free nature. Users do not need to regularly check and refill water levels, reducing the time and labor required for upkeep.

- Safety Features: The sealed design greatly minimizes the risk of acid spillage and gas release, making it safer for both users and the environment.

- Durability: Starved cell batteries typically offer a longer lifespan compared to traditional lead-acid batteries, provided they are used under optimal conditions.

- High Performance: With lower internal resistance, they can provide more consistent and efficient power delivery, even in demanding construction environments.

- Wide Temperature Range: They are designed to perform reliably across a broad range of temperatures, from very cold to very hot environments.

- Fast Charging: The design supports faster charging cycles, which is crucial for operations where downtime needs to be minimized.

Drawbacks of Starved Cell Batteries

While starved cell batteries offer numerous benefits, they are not without their drawbacks.

- Higher Initial Cost: Starved cell batteries tend to be more expensive upfront compared to traditional lead-acid batteries, which can be a limiting factor for budget-conscious projects.

- Sensitivity to Overcharging: Despite overcharge protection features, they are still sensitive to incorrect charging practices. Improper charging can significantly shorten their lifespan.

- Less Flexibility in Installation: Because they are sealed units, once they are installed, they cannot be serviced or altered, which limits flexibility in certain applications.

- Weight: These batteries can be heavier than their counterparts, which might present challenges in portable applications or where weight is a critical consideration.

- Specific Charging Requirements: They often require specific types of chargers that are compatible with their internal design and chemistry, which might necessitate additional investments.

Comparative Features

To better understand the distinctions, here’s a brief comparative table focusing on several key features:

| Feature | Starved Cell Battery | Traditional Lead-Acid Battery |

|---|---|---|

| Maintenance | Low to none | High, requires water topping |

| Safety | High, sealed design | Moderate, risk of leaks |

| Lifespan | Longer | Shorter |

| Initial Cost | Higher | Lower |

| Flexibility | Less Flexible | More Flexible |

| Weight | Heavier | Lighter |

| Charging Requirements | Specific Chargers Needed | Standard Chargers |

For a more detailed analysis on the practical implications of using starved cell batteries in different scenarios, review this resource from the Exploratorium.

Extending the Lifespan of Starved Cell Batteries

Proper Charging Practices

One of the most critical factors in extending the life of a starved cell battery is adhering to proper charging procedures. Follow these guidelines for optimal results:

- Use Compatible Chargers: Always use chargers specifically designed for starved cell batteries. These chargers typically offer controlled voltage and current to prevent overcharging.

- Avoid Deep Discharges: Regularly allowing the battery to fully discharge can significantly reduce its lifespan. Try to recharge the battery before it drops below 50% capacity.

- Follow Manufacturer Recommendations: Adhere to the manufacturer’s guidelines for charging intervals and rates to ensure longevity.

Temperature Control

Temperature plays a significant role in battery health. Maintaining the battery within an optimal temperature range can prolong its life.

- Store Batteries Properly: Store batteries in a cool, dry place when not in use. Avoid extreme temperatures which can degrade the battery’s components faster.

- Implement Cooling Solutions: For applications in high-temperature environments, consider adding cooling systems or ventilation to keep the battery compartment cool.

- Monitor Temperature During Use: Using temperature monitoring systems can help you take proactive measures if the battery begins to overheat.

Regular Inspections and Maintenance

Even though starved cell batteries are low-maintenance, periodic inspections can identify potential issues before they become serious problems.

- Inspect for Physical Damage: Regularly check the battery housing for cracks, leaks, or corrosion which could indicate internal damage.

- Monitor Performance: Keep track of the battery’s performance. Declining capacity or efficiency may signal it’s time for preventive maintenance.

- Clean Battery Terminals: Ensure the terminals are clean and free from corrosion to maintain good electrical connectivity.

Preventive Measures

Consider implementing preventive measures that address potential issues before they occur.

- Use Battery Management Systems (BMS): Invest in a BMS that can provide real-time data on battery health, charge levels, and temperature to optimize usage.

- Cycle Batteries Appropriately: Avoid short cycling by ensuring the battery goes through proper charge and discharge cycles, which can help preserve its capacity.

- Install Surge Protection: Protect the battery from voltage surges, which can damage internal components and reduce lifespan.

Usage Best Practices

Adopting best practices in the utilization of starved cell batteries can make a considerable difference in their longevity.

- Load Management: Avoid placing constant high loads on the battery, which can lead to excessive drain and heat buildup.

- Optimized Usage Patterns: Use the batteries in cycles that fit their design specifications to avoid stressing the internal components.

- Automated Systems: Where possible, use automated systems to manage load and recharge cycles for consistency.

For additional insights on maximizing the lifespan of starved cell batteries, check out this [comprehensive guide on the effects of proper usage](https://www.exploratorium.edu/mobile) from Exploratorium.

Starved Cell Batteries: The Conclusion

Starved cell batteries, known for their maintenance-free and sealed design, offer significant advantages such as longer lifespan, improved safety, and efficient performance.

Their unique construction, featuring an absorbed electrolyte in a fiberglass mat, allows for benefits in various applications, especially in construction.

However, they also come with considerations like higher upfront costs and specific charging requirements.

Understanding and leveraging these batteries can lead to optimized use in different operational environments.

Frequently Asked Questions – FAQs

What are starved cell batteries?

Starved cell batteries, or valve-regulated lead-acid (VRLA) batteries, utilize an absorbed glass mat or gel to immobilize the electrolyte, offering maintenance-free benefits and enhanced safety features.

Where are starved cell batteries commonly used?

They are often used in construction equipment such as scissor lifts, backup power systems, and portable power tools.

They are also found in telecommunications, uninterruptible power supplies (UPS), and marine applications.

What are the key advantages of starved cell batteries?

These batteries offer maintenance-free operation, a longer lifespan, high efficiency, safety through a sealed design, and better performance across a wide temperature range.

They also support faster charging cycles and have lower spillage risks.

What are the potential drawbacks of starved cell batteries?

Drawbacks include higher initial costs, sensitivity to overcharging, less installation flexibility due to the sealed design, heavier weight, and the need for specific charging equipment.

Improper charging practices can significantly reduce their lifespan.

How can I extend the lifespan of my starved cell battery?

Ensure you use compatible chargers and avoid deep discharges.

Store batteries in a cool, dry place and monitor their temperature during use.

Regularly inspect the battery for physical damage and maintain clean terminals.