Introduction to Line Conductor Stringing

Have you ever stopped to wonder about the complex networks of power lines and telecommunications cables around us?

Their installation isn’t as simple as just laying them out. A crucial process lies behind their setup known as line conductor stringing. In this article, we will delve into the ins and outs of line conductor stringing, the integral role of rope, and the importance of the unassuming stringing block in the construction world.

We’ll be looking at why certain types of ropes are chosen over others, the detailed process of stringing conductors, and crucial safety measures that need to be adhered to.

So, whether you’re in the construction field, a tech enthusiast, or simply curious, let’s unravel the not-so-simple world of line conductor stringing together.

Table of Contents

Construction Concept: Stringing Block

A Brief Overview of the Stringing Block

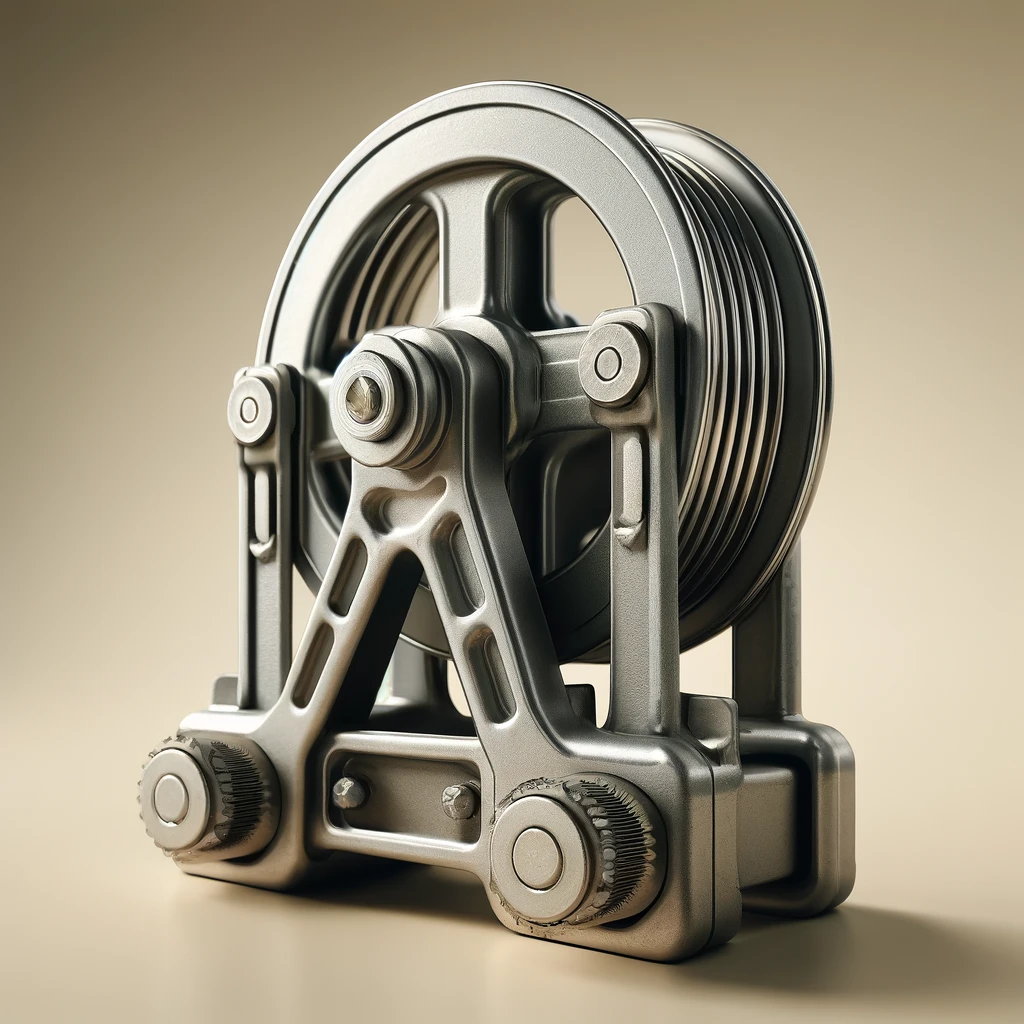

A stringing block, a key term in the field of construction, is an indispensable tool, especially in projects related to power transmission and telecommunication networks. It is typically comprised of a pulley system encased within a sturdy, weather-resistant shell and is primarily used to guide and protect cables and wires as they are unreeled or laid out during construction or maintenance tasks.(source)

Key Functions of a Stringing Block

Guide Wires and Cables: Its fundamental function is to effectively manage the direction and flow of heavy-duty cables and wires as they are unspooled.

Prevent Damage: The robust construction of the stringing block protects valuable conductors from potential damage during the stringing process.

Enhance Efficiency: By facilitating smoother cable and wire handling, it enhances the overall efficiency and safety of the construction process.

Components of a Stringing Block

Understanding the key components of a stringing block can provide additional insights into its function and usage.

| Component | Description |

|---|---|

| Sheave | This is the wheel with a grooved rim on which the wire or cable runs. It’s built to withstand the weight and pressure exerted when large quantities of cable are passed over it. |

| Frame | The stringing block’s frame secures and houses the sheave. It’s typically constructed from durable materials to resist harsh weather conditions. |

| Bearing System | This allows the sheave to rotate freely, maintaining smooth motion during the stringing process. |

With this basic understanding of a stringing block’s function and principal components, workers and construction enthusiasts alike can appreciate this vital tool’s role in successful and efficient construction operations.

The Art of Stringing in Line Conductor Using Rope

Introduction to Line Conductor Stringing

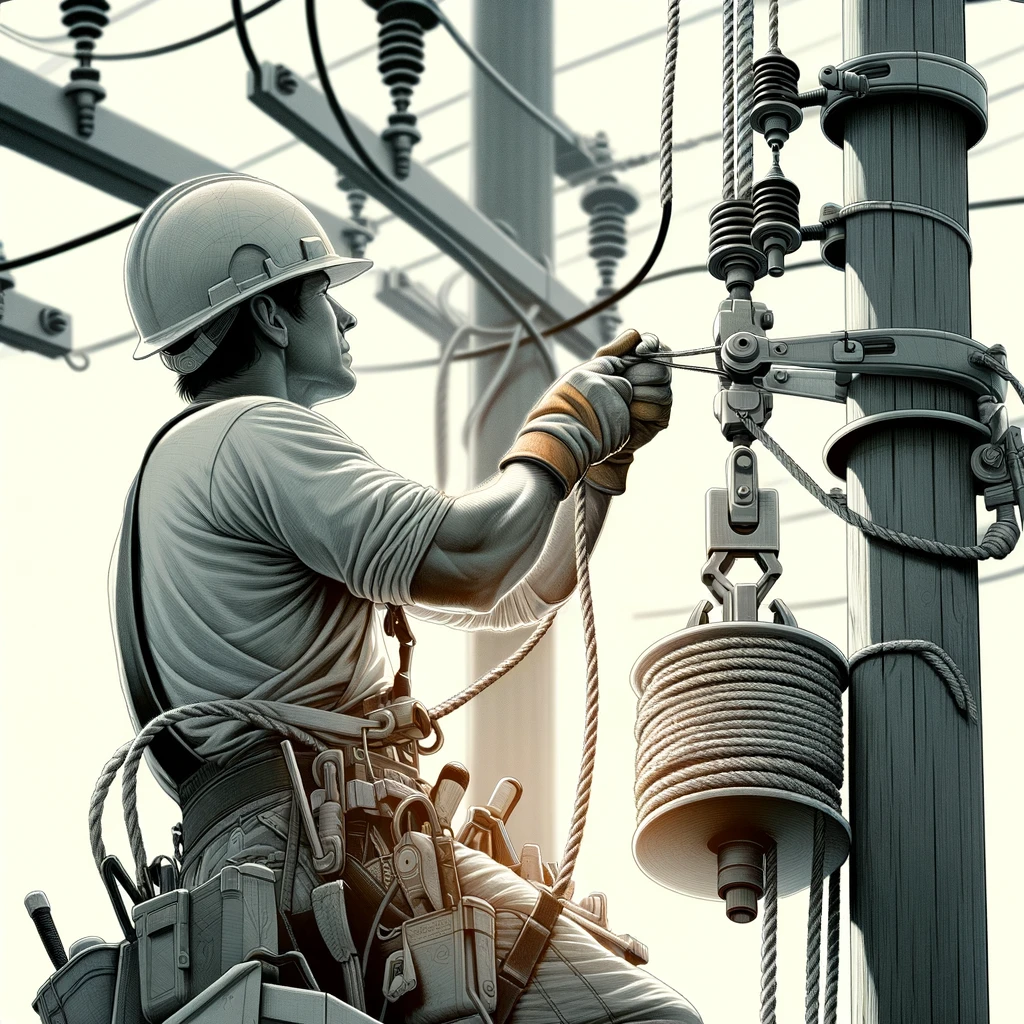

In the construction realm, particularly pertaining to power lines and telecommunications, a rope is quintessential for stringing in line conductors. The utility of a durable and robust rope stems from its primary role in threading or ‘stringing’ through a conductor, such as a cable or a wire, via a stringing block.

Why Use a Rope for Line Conductor Stringing?

The choice of using a rope for stringing operations must be guided by its inherent characteristics, optimal tensile strength, flexibility, and resistance to environmental exposure. Furthermore, a rope’s role in stringing can be categorized under the following heads:

Provision of Path: Before the actual conductors are installed, the rope presents an effective pathway, allowing conductors to be strung along the intended course.

Stability and Safety: When tensioning the conductors, the rope offers necessary stability, averting potential snags and maintaining safety in operations.

Bearing the Tension: The rope takes on a significant portion of mechanical stress during the stringing process, thereby preventing undue strain on the conductors themselves.

Line Conductor Stringing: The Process

Line conductor stringing essentially involves the deployment of cables or wires over a set of pylons or towers, ensuring secure electrical or telecommunication networks. The process commences with the threading of a rope into the stringing block, which then guides the line conductor into its designated place.

Process Steps:

The rope is first threaded or ‘reeved’ through each stringing block along the path of the conductor.

Next, the line conductor is attached to the rope using grip devices.

After securing the conductor, it is then pulled by the rope through each stringing block, effectively stringing it along the designated path.

Necessity of Rope in Efficient Stringing Operations

The importance of a rope in stringing line conductors is paramount. Its usage not only ensures the smooth and secure installation of conductors but also mitigates potential risks, facilitating efficient and safe operations. As BMP Rope Access describes, commercial rope usage in modern business, especially in sectors like telecommunications and power transmissions, highlights its intrinsic role in maintaining network connectivity and power supply.

The Practical Details of Line Conductor Stringing

Types of Ropes Used in Line Conductor Stringing

In line conductor stringing, the quality and type of rope used can significantly impact the efficiency and safety of the process. The two common types of ropes used are synthetic ropes and wire rope. Synthetic ropes, such as nylon or polyester, are lauded for high strength-to-weight ratios, flexibility, and great resistance to environmental factors. Wire ropes, on the other hand, are chosen for their extraordinary tensile strength, longevity, and reliable performance under intense pressure.

Selecting the Right Rope for the Job

The selection of rope should ideally be based on a few considerations:

Type of Conductor: The nature of the cable or wire being strung impacts the choice of rope. Heavier conductors might require a wire rope, while lighter ones could be operated with synthetic ropes.

Environmental Conditions: Ropes must withstand local weather, including temperature variations and UV exposure. Wire ropes perform well in harsh conditions, while synthetic ropes resist weathering and UV degradation.

Tensile Strength: The load-bearing capacity of the rope should exceed the total weight of the conductor, considering the strain it undergoes during the stringing process.

Maintaining Safety Standards during Line Conductor Stringing

Important Safety Measures

Line conductor stringing, although a routine task, requires careful planning and adherence to safety standards to avoid possible accidents and ensure employee wellbeing. Here are some fundamental safety measures:

Regular Equipment Check: Regular maintenance and inspection of stringing equipment, including ropes and blocks, are essential to prevent equipment failure.

Safety Training for Personnel: Workers should be adequately trained in handling equipment and understanding potential risks associated with line conductor stringing.

Use of Personal Protective Equipment: All personnel should be equipped with necessary personal protective equipment like gloves, helmets, and safety harnesses.

Handling Challenges during Line Conductor Stringing

Despite careful planning, unpredictable challenges may arise during the stringing process. Such hurdles could include adverse weather conditions, difficult terrain, or unexpected equipment malfunctions. These issues highlight the necessity of contingency planning and the availability of backup equipment.

Reference in Safety Guidelines

The Occupational Safety and Health Administration (OSHA) offers comprehensive guidelines on safety measures to be followed during power transmission tasks, emphasizing routine equipment inspection, effective safety training, and adherence to personal protective equipment standards.

A Comprehensive Look at Synthetic and Wire Ropes

Synthetic Ropes: A Deep Dive

Synthetic ropes, made of materials such as nylon, polyester, or polypropylene, are increasingly used in a variety of industries, including construction, utilities, and telecommunications. Aside from their impressive strength-to-weight ratio, they offer several notable advantages:

Floating Ability: Unlike wire ropes, synthetic ropes are lightweight and can float on water, expanding their range of use in various applications.

Weather Resistant: They possess exceptional resistance to UV radiation and can withstand a wide range of temperatures, making them suitable for use outdoors.

Flexibility: Synthetic ropes can easily conform to uneven surfaces and are easy to knot, enhancing their usability.

Wire Ropes: An Examination

Wire ropes, made of steel or other strong metal materials, are renowned for their exceptional durability and strength. They are selected for heavy-duty applications, where their intrinsic qualities come to the fore:

Tensile Strength: Wire ropes possess a high tensile strength, allowing them to handle substantial loads and tensions effectively.

Durability: They are notably durable and resistant to wear-and-tear, especially under harsh environmental conditions.

Non-Elastic: Unlike synthetic ropes, wire ropes don’t stretch easily under load, providing a consistent length in varying load conditions.

The Role of Ropes in Tensioning Operations

While setting up the line conductor path, the process doesn’t end at mere stringing. Tensioning is a crucial part of the process that ensures the successful and functional installation of conductors. Regardless of their type, ropes are integral to this process, offering much-needed tension pull to the conductor strings while maintaining operational safety and efficiency.

Delving into Modern Line Conductor Stringing Techniques

Use of Tension Stringing Method

The tension stringing method is a modern technique extensively adopted in the placement of line conductors. In this method, both the rope and the conductor are continuously tensioned during the stringing process. This approach ensures that conductors do not touch the ground, minimizing the potential for conductor damage and increasing the safety of operations.

Employment of Ground-Based Methods

In some cases, generally in areas with difficult terrain or dense vegetation, ground-based methods can be employed. These methods could include the use of tensioners and pullers on the ground level, allowing workers to manage the stringing process with more ease and control. Though this method requires careful execution, it offers a practical solution when aerial methods are impractical or unsafe.

The Rise of Helicopter Stringing

For very large projects or in challenging environments, helicopter stringing is becoming an increasingly popular method. This technique involves using a helicopter to carry and place the rope or pilot line across the structure or path. While this method is more cost-intensive, it dramatically increases the speed of the stringing process and is often the only feasible solution in mountainous or densely forested regions.

Practical Considerations During Line Conductor Stringing

Coordination and Synchronization in Operations

Proper coordination and synchronization among the crewmembers is crucial to successful and safe line conductor stringing operations. For example, the rope must be properly managed to prevent tangles, and tension must be monitored consistently to avoid undue strain on the conductor. Consequently, maintaining seamless communication among the team can make a significant difference in operational efficiency and safety.

Accurate Calculations and Predictions

Acquisition of accurate data and making correct calculations is a critical part of line stringing operations. This can include calculating the weight of the conductor, understanding the elasticity of the rope, anticipating the pulling tension, and making necessary allowances for factors such as sagging, wind velocity, and temperature effects. Such accurate measurements and predictions ensure the smooth execution of the stringing process while avoiding potential operational challenges.

Dealing with Environmental Factors

Considering environmental factors is an important aspect of line conductor stringing operations. Elements like wind velocity, temperature, and precipitation can affect the tensioning process and the overall installation of conductors. For instance, conductors tend to contract in cold weather and expand in hot weather — factors that need to be accounted for during installation. Therefore, a keen understanding of these environmental influences can lead to more efficient and safer operations.(source)

In Conclusion: The Vital Role of Stringing Blocks and Ropes in Construction

Stringing blocks and ropes are fundamental tools in the fields of construction, power transmission, and telecommunications. They play a pivotal role in guiding and protecting cables and wires, enhancing the overall efficiency and safety of installation tasks.

The stringing block, with its well-constructed sheave, frame, and bearing system, and the rope, selected for its tensile strength, flexibility, and weather resistance, work in unison to ensure smooth and successful stringing operations. Furthermore, the understanding of modern line conductor stringing techniques provides improved ways to approach complex projects.

Yet, it is important to note that safety standards, precise calculations, and the impact of environmental factors should always be considered to optimize the performance of these tools. Finally, ongoing advances in rope materials and stringing techniques hint at a future of more efficient, safer, and even more adaptable construction processes.

Frequently Asked Questions – FAQs

What is a stringing block used for?

A stringing block is used to guide and protect heavy-duty cables and wires as they are unreeled or laid out during construction or maintenance tasks.

Why is a rope important in line conductor stringing?

A rope provides a stable pathway for the line conductor, supports the tension during the stringing process, and ensures safe and efficient stringing operations.

What are the key considerations when selecting a rope for stringing?

The type of conductor, the environmental conditions, and the tensile strength of the rope are key considerations when selecting a rope for stringing.

What are some modern techniques for line conductor stringing?

Modern techniques for line conductor stringing include the tension stringing method, ground-based methods, and helicopter stringing.

What are the essential safety measures during line conductor stringing?

Safety measures include regular equipment check, safety training for personnel, use of personal protective equipment, and handling potential challenges.