Decoding Construction Terminology: Fused Cutout

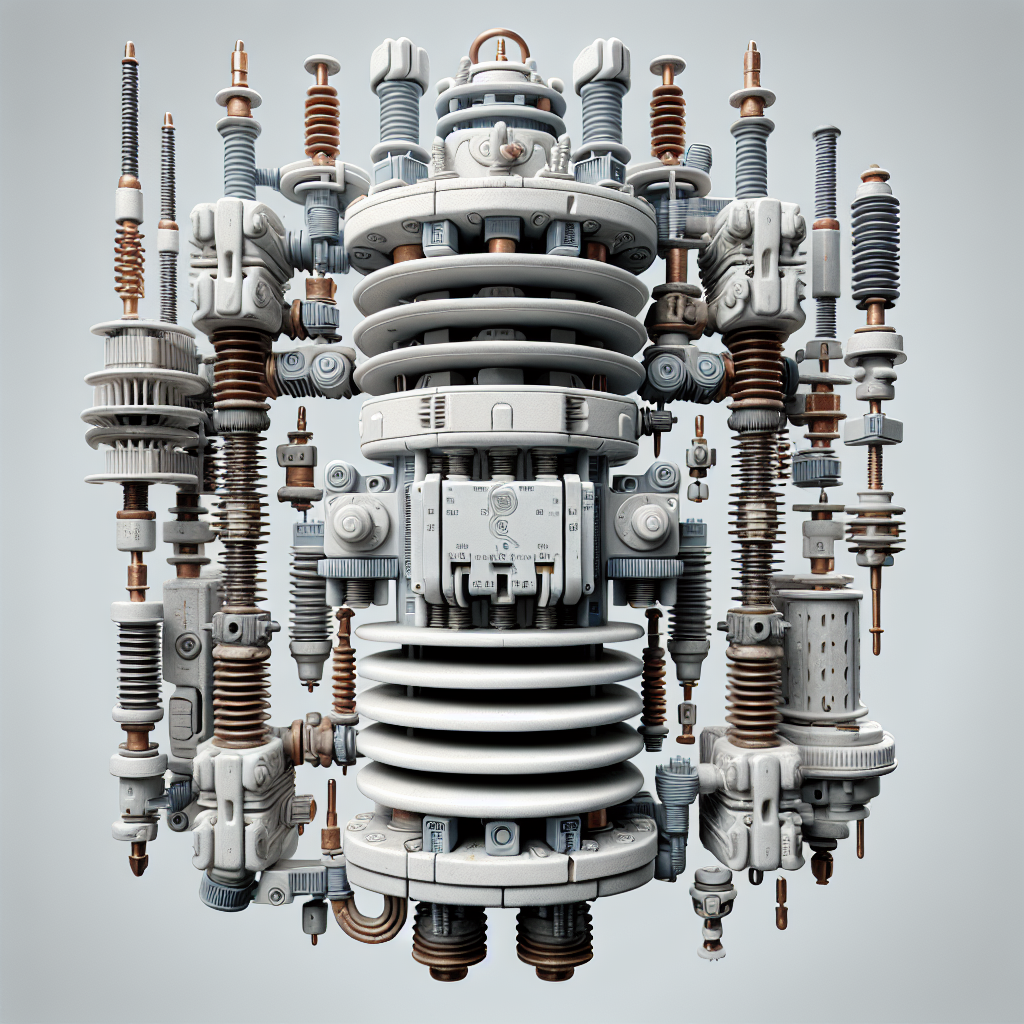

A “Fused Cutout”, in the domain of construction, represents a significant component within electrical distribution systems.

This device, characterized by a blend of fuse and switch, plays an integral role in safeguarding these systems against overloads and short circuits.

In a practical scenario, when applied to a construction project, Fused Cutouts serve as sentinel devices for power lines, ensuring safety and reliability of the electrical provision.

Understanding Cutouts in Construction

When it comes to construction, cutouts play a crucial role in various applications. Understanding the different types of cutouts is essential for successful project completion. Let’s dive into the various types of cutouts commonly used in construction:

1. Electrical Cutouts

Electrical cutouts are openings made for electrical outlets, switches, and other electrical components. These cutouts are essential for proper wiring and installation of electrical fixtures in a building.

Key Features:

- Commonly rectangular or square in shape

- Located at specific heights and distances according to electrical codes

- May require additional safety measures such as fire-rated boxes

2. Plumbing Cutouts

Plumbing cutouts are strategic openings created for plumbing fixtures such as sinks, faucets, and drainage pipes. Properly positioned plumbing cutouts ensure smooth installation and functionality of plumbing systems.

Key Features:

- Varies in size and shape based on the plumbing fixture being installed

- Positioned to align with water supply and drainage lines

- May require reinforcement for heavy fixtures such as bathtubs

3. HVAC Cutouts

HVAC cutouts are specific openings designed for heating, ventilation, and air conditioning components. These cutouts facilitate the installation of HVAC ducts, vents, and units to ensure proper airflow and climate control within a building.

Key Features:

- Can be circular, rectangular, or custom-shaped based on HVAC equipment requirements

- Positioned for optimal air circulation and efficiency

- Require coordination with other trades for seamless integration

4. Structural Cutouts

Structural cutouts are openings made in walls, floors, or ceilings to accommodate structural elements such as beams, columns, and support systems. These cutouts are crucial for maintaining the integrity and stability of a building’s structure.

Key Features:

- Engineered to preserve load-bearing capacity

- Maintain safety and compliance with building codes

- May involve reinforcement or framing modifications

Understanding the different types of cutouts in construction is key to efficient project execution and ensuring the functionality and safety of the built environment. Proper planning and coordination of cutouts with various trades are essential for a successful construction project.

The Importance of Fuse Cut Out in Electrical Systems

A specific type of electrical cutout, the fuse cutout, holds significant importance in electrical systems. Like all other cutouts, its purpose aligns with system functionality, safety, and efficiency. But it exhibits unique characteristics and serves specific roles that set it apart.

What is a Fuse Cut Out?

A fuse cutout or a cutout fuse is a combination of a fuse and a switch used in electrical distribution systems. It’s designed to protect the downstream circuitry from overcurrent scenarios, such as short circuits or surges, that could otherwise cause significant damage or even lead to electrical fires.

Key Components:

- Tube: The tube contains the fuse and extends between the cutout’s upper and lower contacts

- Fuse Link: The fuse link is a wire with a known melting point that’s calibrated according to the current rating of the circuit it protects.

- Contacts: The upper and lower contacts connect the fuse tube to the circuit and hold it in place.

Why is a Fuse Cut Out Important?

The fuse cutout serves a dual purpose: protecting the electrical infrastructure and interrupting the power supply during faults. The fuse link within the fuse cutout melts when it encounters high currents, triggering the automatic isolation of affected lines.

Key functions:

- Prevents Damage: The fuse cutout safeguards electrical components and infrastructure by limiting the amount of current flowing in the network.

- Maintains Safety: By disconnecting overcurrents, fuse cutouts reduce the risk of electrical fires, improving safety for individuals and property.

- Facilitates Repairs: After interrupting the power supply, fuse cutouts make it safer for electrical workers to perform necessary repairs.

Choosing the Right Fuse Cut Out

Choosing the right fuse cutout requires careful considerations surrounding the specific electrical distribution system’s design and needs.

Factors to consider:

- Current Capacity: A fuse cutout must have an adequate current capacity to handle the maximum load in the circuit without melting the fuse link prematurely.

- Voltage Rating: The voltage rating should be compatible with the circuit’s voltage to avoid potential issues.

- Mounting Option: The fuse cutout needs to be properly mounted, typically available options include pole-top, crossarm and underhung depending on the distribution system design.

Conclusion

In sum, a fuse cutout proves instrumental in ensuring the safe and efficient operation of electrical systems. It not only acts as a safeguard mechanism but also contributes to system longevity. With careful selection and proper installation, fuse cutouts can greatly enhance the performance and security of any electrical distribution system.

Additional Aspects of Fuse Cutouts

After understanding the basic concept, operation, and significance of a fuse cutout, it’s necessary to get acquainted with additional aspects, including the various types and the process of replacing a blown fuse in a cutout.

Types of Fuse Cutouts

Fuse cutouts come in various types, and the decision regarding their use could be influenced by factors such as the purpose of the circuit, the characteristics of the load, and the specifications of the power supply.

Dropout Fuse Cutouts

Dropout fuse cutouts are used predominantly in outdoor systems serving electricity distribution and telecommunication applications. When the fuse link melts due to overcurrent, the cutout’s assembly drops out, making it evident that a fault has occurred.

Expulsion Fuse Cutouts

Expulsion fuse cutouts utilize the gases produced by the arcing caused when the fuse link melts to create a high-pressure scenario. This pressure aids in quenching the arc and consequently isolating the faulted part of the circuit.

Replacing a Blown Fuse in a Fuse Cutout

In a practical scenario, when a fuse link melts due to an overcurrent situation, it needs to be replaced to restore the operation of the circuit. Understanding the steps to replace a fuse link accurately and safely is crucial.

Procedure for Fuse Replacement:

- Switch Off Power: Prior to replacing the fuse link, it’s crucial to shut off power to the circuit to avert electrical hazards.

- Remove the Old Fuse: Carefully open the fuse cutout and take out the old, melted fuse from its holder. Use insulated gloves to prevent shock risk.

- Insert the New Fuse: Insert a new fuse of the same current rating into the holder and firmly secure it in position.

- Switch On Power: After ensuring the fuse is correctly positioned and secured, restore power to the circuit. Regular operation should resume if no other faults exist in the circuit.

Conclusion

Understanding the different types of fuse cutouts and knowing how to replace a blown fuse are crucial aspects of managing an electrical distribution system. Through the right selection of fuse cutouts and accurate maintenance procedures, one can significantly increase system reliability and safety. Always remember that dealing with electrical systems demands a sound understanding of safety norms and precautions to prevent unintended harm.

Understanding Cutouts in Power Systems

In specific reference to power systems, an important application of the cutout concept is found in the form of ‘cutouts on power lines’. These power line cutouts, similar to the fuse cutouts discussed earlier, play an instrumental role in ensuring the efficiency and safety of power transmission and distribution networks.

What is a Cutout on Power Line?

A cutout on a power line is an automatically operated electrical switch that is designed to protect the electrical circuit from damage caused by excess current typically resulting from an overload or short circuit. It functions as a damage prevention solution by creating an open circuit in the event of a dangerously high current flow.

Key Features:

- Automatically disconnects upon detection of overcurrent

- Often designed to withstand harsh conditions, given the outdoor installation

- Can be manually operated for maintenance or emergency purposes

Integral Role of Power Line Cutouts

Power line cutouts form an integral part of power distribution networks worldwide thanks to their ability to maintain system reliability and prevent widespread damage.

Primary Functions:

- Detect and Isolate Faults: Power line cutouts act swiftly to detect overcurrents and isolate the faulty section of the power line, preventing further damage.

- Facilitate Low Cost Maintenance: By limiting damage to a specific section of the network, cutouts help reduce repair and maintenance costs.

- Aid in Safety Protocols: The quick action of power line cutouts enhances safety for maintenance crews and the general public, reducing the chances of electrical fires and other hazards.

Considerations for Power Line Cutouts

Though the considerations for power line cutouts may be similar to those for fuse cutouts, a few unique circumstances dictate additional criteria for selection and installation.

Factors to Consider:

- Climate Conditions: Given their outdoor installation, power line cutouts should be chosen after considering the climate and environmental conditions of the area.

- Interference Range: The power line cutout’s ‘trip setting’ or the current level at which it operates should be considered to avoid unnecessary network disruptions.

- Installation Considerations: Factors like height from the ground, clearance from buildings, and proximity to trees can influence the effectiveness of the cutout and should be considered during installation.

Conclusion

To sum up, cutouts on power lines are important protective devices that safeguard electrical circuits in power distribution networks. Their ability to automatically detect and isolate faults not only preserves the network’s functional integrity but also significantly reduces maintenance costs and enhances safety. By considering important factors like environmental conditions and installation requirements, one can ensure the effective operation of power line cutouts. In conclusion, the incorporation of various types of cutouts is essential in construction to accommodate different building components and systems. Electrical cutouts ensure proper installation of electrical fixtures, plumbing cutouts allow for the seamless incorporation of plumbing systems, HVAC cutouts facilitate efficient climate control, and structural cutouts maintain structural integrity.

Each type of cutout is distinct in its purpose and features, requiring specific positioning and considerations to fulfill its intended function. Understanding and planning for these cutouts are critical for achieving a well-coordinated and functional construction project. Proper coordination among different trades is vital to ensure the seamless integration of these cutouts into the overall building structure.

In essence, a comprehensive understanding of the types and requirements of cutouts in construction is imperative for the successful execution of projects, ultimately contributing to the safety, functionality, and longevity of the built environment.