Exploring the Significance of Ladder Diagram (LD) in Construction

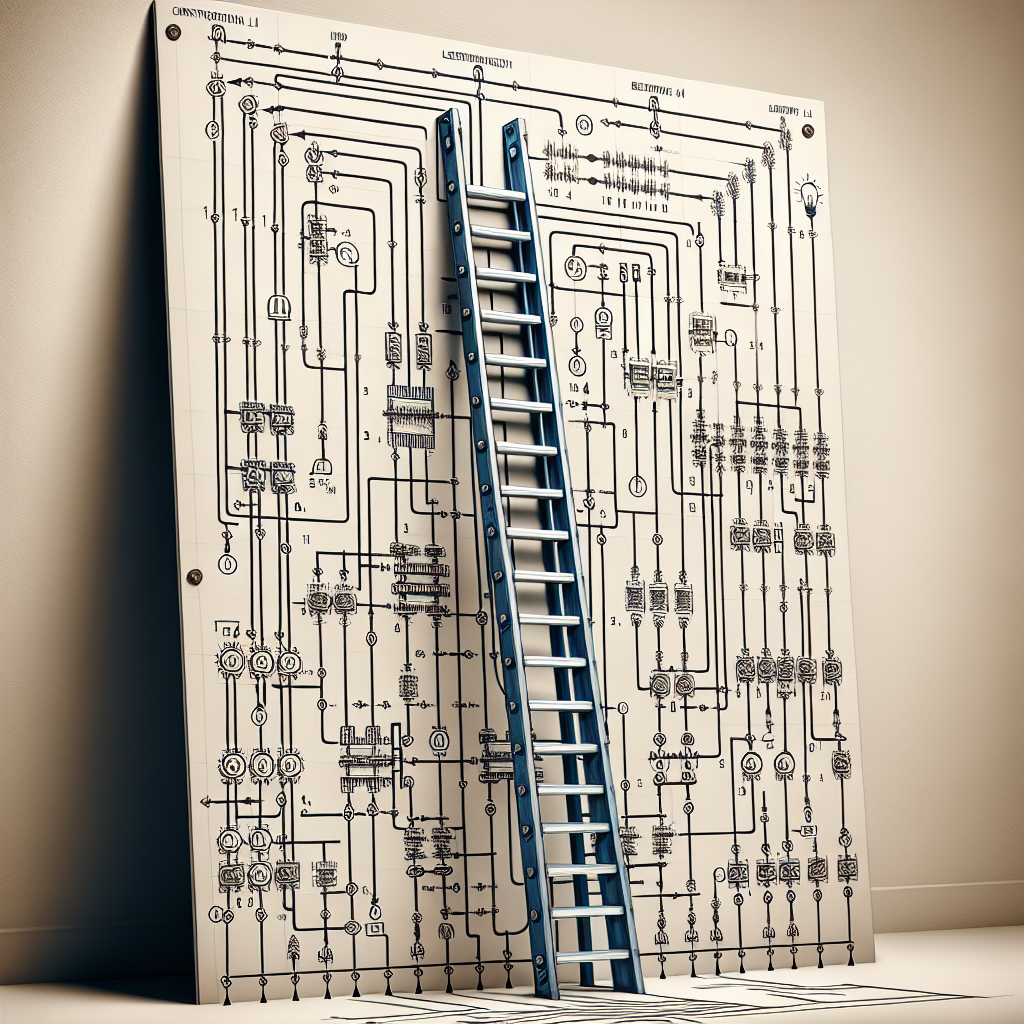

The term ‘Ladder Diagram’ (LD) within the scope of construction is not just a symbolic title. It is a graphical language originally devised to document the design and construction of relay racks used in manufacturing and process control.

Each device in the relay rack would be represented by a symbol in the ladder diagram. Time has witnessed the evolution of this concept, now catering to a wider range of applications within construction.

Succinctly put, it allows engineers to visually organise and control complex systems. This power tool of visualisation means that even laymen can get an idea of what goes on behind the intricate art of building factories or skyscrapers.

Understanding Construction Terms: What is LD in Ladder Diagram?

When talking about construction terms, the language can often be confusing. One term that frequently comes up when discussing electrical systems or automation in buildings is ‘LD’, which stands for Ladder Diagram. So what exactly is LD in a ladder diagram? Let’s break it down.

Definition of LD in Ladder Diagram

LD in a ladder diagram refers to the logical structure that is used to organize and visualise electrical logic schemes. It’s a language of graphical symbols, with a structure that resembles a ladder, hence the name.

The Composition of a Ladder Diagram

Ladder Diagrams (LD) are made up of a series of horizontal rungs, each one containing a set of logical expressions or operations between various devices and objects. Each rung represents a specific function or operation taking place within a system.

Why is LD Important in Construction?

LD is important in construction, especially in electrical system design, as it provides a clear, visual method for tracing electrical circuits and understanding how different systems interact with each other. This can help facilitate better planning, troubleshooting and maintenance of building electrical systems.

Key Elements of a Ladder Diagram

In understanding the LD, it is important to recognize its key elements:

- Rungs: These are the lines making up the ladder. Each rung represents a control circuit or function.

- Tracks: The vertical lines or ‘rails’ framing the ladder, representing the power source of the diagram.

- Symbols: Various symbols are used to illustrate the different components included in each rung, such as switches, relays and actuators.

A Closer Look at LD Symbols In Construction

One particular area that can cause confusion in understanding LD is the use of symbols. These are categorized based on their functions:

| Symbols | Functions |

|---|---|

| Contact | Representing switches that control power flow in the circuit |

| Coil | Representing output elements such as motor starters, status lights, etc. |

| Timer | Representing elements used to delay or stretch time intervals |

| Counter | Representing components that count instances of events |

To fully understand and effectively use ladder diagrams in construction, a strong understanding of these symbols is crucial. It may be beneficial to use a reference guide when interpreting these diagrams.

Final Thoughts

LD in a ladder diagram is a primary language in building and industrial automation. It provides a clear, logical way of visualising and interpreting electrical circuits and systems. Given its importance, gaining a solid understanding of LD is key to managing projects effectively in construction and related fields.

Ladder Diagrams in Practical Applications

For a more comprehensive understanding of ladder diagrams, it’s crucial to explore their practical applications in the construction and automation industry. The language of a Ladder Diagram, though at first glance may appear complex, provides an indispensable tool for project coordination and troubleshooting.

Applications in Building Automation

Building Automation Systems (BAS) extensively utilize LD for seamless operations. These systems monitor and control the building’s mechanical, electrical, and plumbing (MEP) systems, and LD helps to understand the operational logic.

Elevators and Lifts

Ladder diagrams are at the heart of elevator control systems. They outline the logical sequence of operations empowered by binary logic controls. For instance, LD can outline the operation from the press of a button on a specific floor, the steps taken by the elevator system to position the car accordingly, and what happens after reaching the desired floor.

Lighting Control

In complex buildings with intricate lighting systems, LD assists in the effective configuration, control, and troubleshooting of circuits. From simple lighting control to programmable sequences for aesthetic or practical operations, LD supports easy interpretation and modification of such systems.

LD in Industrial Automation

Ladder Diagrams play a crucial role in the development, operation, and maintenance of industrial automation systems.

- Robotics: In robot programming, LD affords the opportunity to visualize the logical operations and troubleshoot with ease.

- Manufacturing Line: For various segments of a manufacturing line, LD can map the operations, providing a clearer understanding of steps and potential bottlenecks.

- Machine Control: LD helps visualize the interaction between various machine parts, enabling technicians to effectively understand and maintain the system.

Learning and Implementing Ladder Diagrams

Despite its crucial utility in various sectors, learning and implementing LD isn’t an overwhelming task. Various tools and platforms are available to learn and design Ladder Diagrams such as LDmicro and RSLogix.

- LDmicro: A lightweight tool that allows you to draw and edit Ladder Diagrams, and simulate them on a PC.

- RSLogix: An enterprise solution with a wide range of tools to write and debug Ladder Diagrams and Function Block Diagrams (FBD).

Commencing the journey with an understanding of symbols and their purposes, followed by familiarity with standard operations and use-cases, will empower a professional to command LD with finesse. Online courses and tutorials may also be helpful for learning this skill.

Conclusion

The Ladder Diagram, with its logical clarity and visual approach, facilitates seamless operation, control, and troubleshooting of complex systems in building and industrial automation. A construct of essential symbols, it embodies the interaction and chronological order of operations. With the right learning tools, mastering LD can certainly facilitate smoother projects and easy troubleshooting, uplifting your efficiency in construction and automation endeavors.

Understanding LD Instruction in Programmable Logic Controllers (PLC)

Apart from its widespread usage in electrical system design and building automation, the concept of ‘LD’ also plays a crucial role in the field of Programmable Logic Controllers (PLCs).

Defining LD instruction

In the context of PLCs, ‘LD’ stands for Load instruction, a fundamental approach to processing of data. It’s one of many instructions that are used to build control algorithms in PLC programs.

Working of LD Instruction

LD instruction loads a bit status (either ON or OFF) into a register for further processing. It is generally used at the beginning of a rung, and the status of the specified bit is duplicated onto a relay coil or control bit at the end of the rung.

Importance of LD instruction in PLC

The LD instruction is a key component of PLC ladder logic, providing the ability to perform real-time decision making, control processes and dine-tune system performance.

Examples of LD Instruction

In practical applications, the LD instruction serves different purposes:

- Motor Control: In a system where motors need to be controlled based on certain criteria, the LD instruction can be used to start/stop the motor based on the logic developed.

- Tracking Status: The LD instruction can also track the status of certain equipment or sensors, loading the status value onto the specified address.

Other PLC Instructions Following LD Hierarchy

As part of the PLC instruction set, there are some other instructions that support and supplement the LD instruction. Some of these instructions include:

| Instruction | Definition |

|---|---|

| LDN (Load Not) | An instruction that loads the inverse (or NOT) of a bit status |

| OUT (Output) | An instruction that provides an output based on the preceding LD instructions in the rung |

| AND (Logical And) | An instruction used to ensure that all specified conditions are met before output can be activated |

These instructions, when employed correctly, can result in a robust PLC logic that can efficiently control and automate industrial or construction processes.

Conclusion

The LD instruction is a fundamental concept in PLCs providing a solid foundation to build complex control logics. This unique instruction, along with other complementing PLC instructions, enables automation engineers and developers to translate functional requirements into effective control programs. As a vital part of ladder diagrams and PLC programming, understanding the LD instruction is invaluable for those involved in complex process control and industrial automation.

Defining Functional Block Diagram (FBD)

If you’re familiar with Ladder Diagrams, then the next logical step would be to navigate through Functional Block Diagrams (FBD). Used widely across disciplines, from system engineering to software development, the FBD logically showcases a system’s flow and functional interactions.

A Brief Insight into FBD

Just like LDs, FBDs present a graphical language for designing control solutions. However, the focus of an FBD is on the functions performed by the different system components and the data flow within the system rather than on the control process itself.

FBD in Engineering Contexts

Primarily used in the realms of control engineering and systems engineering, an FBD represents the system’s functions with blocks linked by lines that demonstrate the relationships between different functions.

FBD in Software Programming

In a software context, FBDs are commonly used in structured programming where each block can represent a program function or subroutine. They allow the system’s overall functional organization to be clearly presented and understood.

FBD vs LD: Spotting the Differences

While both FBD and LD are valuable tools for system designers, they contain certain differences in approach and construction that make them unique.

- Focus: Ladder diagrams (LDs) emphasize the control flow, functioning akin to an electrical schematic. In contrast, FBDs emphasize the data flow or the function carried out by different components.

- Structure: An LD’s structure resembles a ladder with rungs, presenting a series of logical expressions. An FBD, however, models a data processing network, showcasing how data moves and changes through the system.

- Application: LD is a tried and tested standard in electrical system design for building and industrial automation. In contrast, FBD is more multi-disciplinary, with applications across control engineering, systems engineering, and software development.

Picking Between LD and FBD: A Practical Approach

Choosing between Ladder Diagrams and Functional Block Diagrams is a matter of considering the problem at hand and the kind of visual depiction that works best.

- Control Process: If your focus is to visualize and program control processes, LDs are the standard choice due to their resemblance to electric circuits.

- Data Flow and Functions: If you need to understand and model the data flow and functions of different components in a system, FBDs would be more suitable.

- Complexity: For complex systems, FBDs might provide a clearer perspective, showing how data is processed and transformed across system parts.

In essence, both LD and FBD have their unique strengths making them suitable for different situations. A competent engineer or developer should preferably be comfortable with both to switch between them as per the requirement.

Conclusion

Understanding Ladder Diagrams (LDs) and Functional Block Diagrams (FBDs) can elevate your skills in system design, automation, and programming. Each serves a unique purpose, and together they offer a powerful repertoire of diagramming tools to model and visualize complex systems. Mastering the art of drawing and interpreting these diagrams can unlock new potentials in the realms of construction, industry automation, control engineering, and software development.

To conclude, the concept of LD, or Ladder Diagram, is an essential tool in the construction domain, specifically in the realm of electrical system design. As we’ve explored, it uses a distinctive logical structure, akin to a ladder, to enable visualizing and tracing electrical circuits. Furthermore, its appropriately named rungs, tracks, and symbols play key roles in elucidating how different systems interact.

From our perspective, familiarizing oneself with the LD’s unique symbols and structure can significantly streamline planning, troubleshooting, and maintenance processes, promoting efficiency. To this end, various reference guides can serve as invaluable resources. In short, developing a well-rounded knowledge of LD in construction can open doors to effective and efficient project management.