Unraveling Cement Soundness

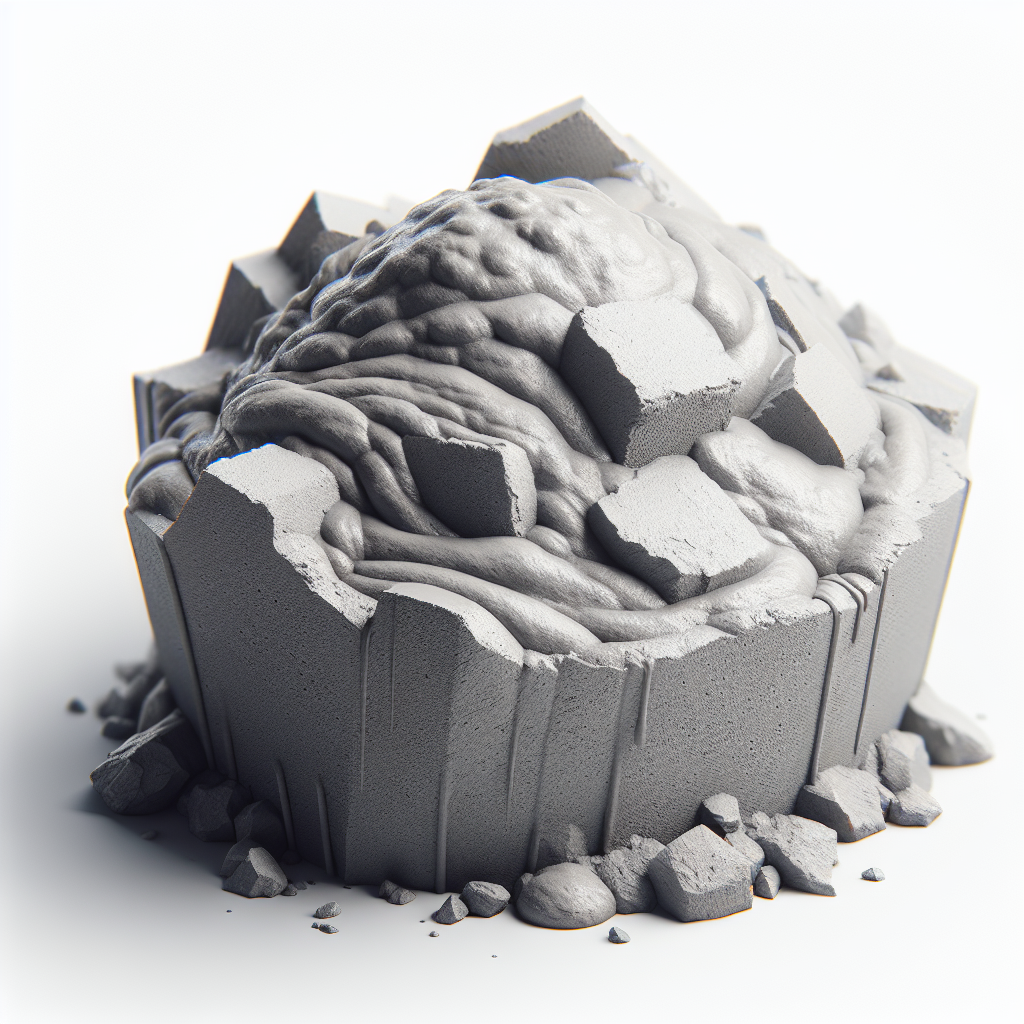

Cement soundness is a vital term in construction; it describes the ability of hardened cement paste to retain its volume after setting.

A sound cement doesn’t show any appreciable expansion, which could cause cracks or disintegration in a structure.

This property is of paramount importance in construction. It assures the stability and durability of a building, preventing future damage and costs. Ensuring sound cement is a key step in quality control within the sector.

Table of Contents

Experimenting the Soundness of Cement in Construction

As a decisive factor influencing the durability and structural integrity of any built structure, the quality of cement is paramount in the construction industry. One of the key quality tests done on cement is to check its ‘soundness.’

Defining ‘Soundness’ in Construction Context

Within the domain of construction, the term soundness refers to the ability of a hardened cement paste to retain its volume after setting, without experiencing delayed destructive expansion.

Sound cement is one that does not exhibit appreciable expansion and thus doesn’t cause disruption and disintegration of concrete. Defected or unsound cement can lead to serious problems in structural integrity including cracking, distortion, and eventual failure of structure. Therefore, a test to determine the soundness of cement becomes indispensable.

Experimenting the Soundness of Cement

There are various standardized procedures for testing the soundness of cement, with the Le Chatelier apparatus being one of the most commonly used approaches.

Procedure of the Le Chatelier Test

The steps involved in conducting the Le Chatelier soundness test on cement are:

- First, prepare a cement paste by mixing cement with water, maintaining a standard consistency.

- Then, fill this paste into a Le Chatelier mould, which is a small split cylinder of specific dimensions.

- The filled mould is then submerged in water at room temperature for 24 hours.

- After 24 hours, the amount of expansion of the cement within the mould is measured, which represents the unsound behaviour of cement.

A cement is considered sound if the amount of expansion measured is within the permissible limits set by relevant standards. For instance, the Indian Standard IS 4031 (Part 3): 1988 specifies a limit of 10mm for the Le Chatelier test.source

Importance of Soundness Test

This straightforward test is invaluable for mishap prevention and ensuring long-term construction durability. It’s important to note that cement’s soundness is only one factor among many to consider in cement selection. Other factors like setting time, compressive strength, fineness and chemical composition should also be taken into account.

It’s through such comprehensive analysis—and by carrying out these numerous tests—that we can ensure the longevity and safety of our buildings and concrete structures.

Understanding and experimenting the soundness of cement is a technical but essential aspect of construction.

It helps in determining the quality of cement, which ultimately contributes to the durability and safety of a built structure. Recognizing the process followed for this test informs construction professionals about the robustness of their foundational building materials.

Le Chatelier’s Test for Cement

As we have acknowledged, Le Chatelier’s test for cement gauges its soundness, ensuring its volume stability post-setting.

The intricate details and stages of this procedure offer more apprehension on its significance and application in construction. Let’s delve into an in-depth analysis and understanding of Le Chatelier’s test for cement.

Underpinning the Science Behind Le Chatelier’s Test

Le Chatelier’s test for cement roots in fundamental principles of chemistry, borrowing its name from Le Chatelier’s Principle.

This principle posits that a shift in any parameter (like temperature, concentration, or pressure) of a balanced chemical system prompts an opposing response to regain equilibriumsource.

In the context of cement testing, the ratio of cement and water instigates the cement’s chemical reaction or hydration. The Le Chatelier’s test observes the adjustments or ‘expansions,’ identifying potential disruptive patterns that could signal unbalanced states, detracting from the cement’s quality.

Detecting Unsound Cement

Historically, unsound cement was linked with an excess of free lime and magnesia. These components can undergo slaking and cause volumetric instability even after setting. The Le Chatelier’s test helps identify such compositions, thereby predicting potential failures in construction due to unsound cement.

Understanding the Role of Le Chatelier’s Mould

Researchers perform the Le Chatelier test using a specific split-cylinder apparatus, known as the Le Chatelier’s mould. This apparatus consists of two identical cylindrical compartments with a hinge at one end, facilitating natural expansion. The apparatus’s design allows for accurate calculations of any unusual expansionsource.

Limitations and Alternatives to Le Chatelier’s Test

Although Le Chatelier’s test has served the construction industry by ensuring the soundness of cement, it has certain limitations.

- The test does not completely incorporate all aspects of a real construction environment, such as varying temperature conditions.

- It does not offer a comprehensive measure of chemical reactivity beyond the 24 hours important in long-term construction stability.

Considering these restrictions, other tests like the autoclave test have been adopted, especially for sulfate resistance and long-term monitoring. These augment the efficacy of soundness tests, supplying a wholistic overview of the cement’s characteristicssource.

Le Chatelier’s test serves a critical role in determining cement soundness and contributes significantly to successful construction practices.

Recognizing the science behind the test, identifying potential pitfalls in utilizing unsound cement, and considering alternative testing methods all help construction professionals maintain structural integrity. So, while cement soundness is but one factor in building quality assurance, it remains a crucial one.

ASTM Standards for Evaluating Cement Soundness

The ASTM (American Society for Testing and Materials) offers internationally recognized standards to gauge the quality and durability of cement. This plays a crucial role in evaluating its soundness. This post discusses the soundness standards set by ASTM, their importance, and the relevant testing methodology.

ASTM C151 Standard – An Introduction to the Autoclave Expansion Test

The ASTM offers standard C151, also known as the Autoclave Expansion Test, for evaluating cement soundness. This advanced method aims to determine the potential for disruptive expansion produced by the hydration of oxides of calcium, aluminum, and silicon in cement on exposure to high-pressure steamsource.

Salient Features of the Autoclave Expansion Test

Compared to the Le Chatelier’s test, this methodology provides a more aggressive environment, simulating the worst conditions cement could subject to in long-term building stability, making it more relevant to construction site conditions.

Delving into the Autoclave Expansion Test Procedure

The Autoclave Expansion Test involves a unique set of steps:

- The cement paste, adhering to a certain water-cement ratio, is used to make concrete bars of specific dimensions.

- These bars are placed in the autoclave (high-pressure steam chamber), then the pressure and temperature are increased over time to a certain value and maintained there for a period.

- The length change of the specimen before and after the autoclave treatment is then calculated.

- This change in length against a specified value determines the cement’s soundness.

According to ASTM C151, if the expansion is more significant than 0.80%, the cement is considered unsoundsource.

The Importance of ASTM Standards in Building construction

ASTM C151 or Autoclave Expansion Test’s utilization is crucial, considering its robustness as a testing standard. This method makes it possible to detect even minor defects, thus preventing potential future structural failures. By minimizing the chance of choosing unsound cement, construction professionals can ensure long-term durability of the construction project.

Discussions around cement soundness generally emphasize the Le Chatelier test. Still, the inclusion of ASTM C151 or Autoclave Expansion

Test provides a broader framework. This advanced testing method ensures that the construction not only adheres to international standards but also succeeds in real-world conditions by verifying the durability of the cement. The testing methods recommended by ASTM thus play a significant role in enhancing the quality and safety of construction projects.

Sounding Off On Cement Soundness

From our perspective, we’ve found the examination of cement’s soundness to be an indispensable step in ensuring long-lasting structural integrity. The Le Chatelier test, for example, is a straightforward but effective tool that helps to measure this critical attribute in cement.

In our experience, the results from this test provide invaluable insights into the potential for future structural disruptions and instabilities. By keeping the expansion measure within the set limits, we can better guarantee the quality and safety of our constructed buildings.

The examination is not an isolated process but forms a part of a comprehensive approach in cement selection and usage. It reinforces the importance of an integrated perspective in understanding that every component, every test, matters when our ultimate goal is to ensure the safety and longevity of our structures.