Understanding Concrete Spalling

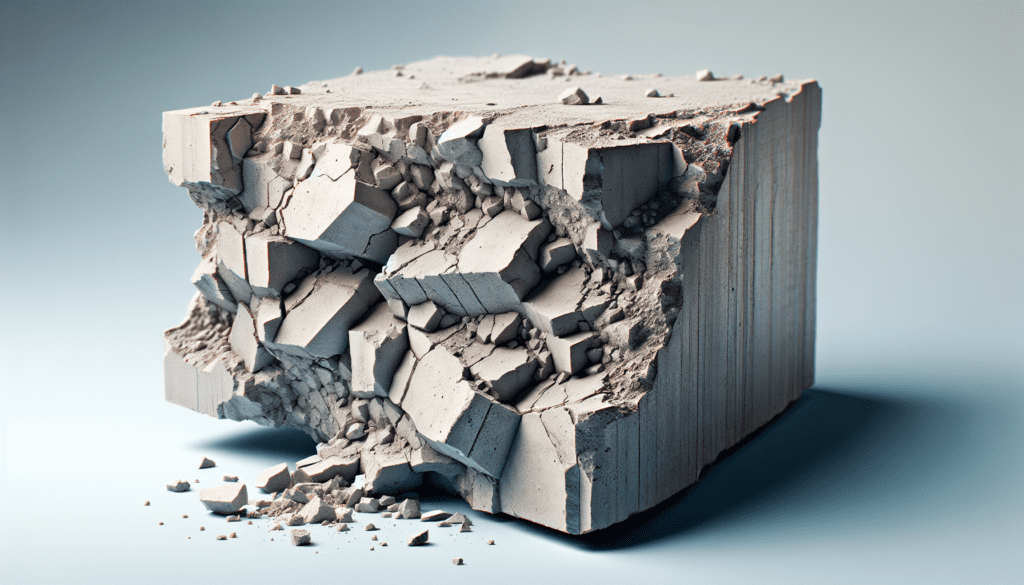

Concrete Spalling, a commonly-used term in the construction industry, refers to the process in which concrete surfaces start to flake, chip, or decay.

Often observed on sidewalk edges, parking areas, or high-traffic roads, this phenomenon results in damages that impact the overall structure and appearance.

Spalling’s relevance to construction is paramount. Not simply an aesthetic concern, but spalling can also signal structural integrity issues.

Poor reinforcement placement, incorrect concrete mix, or exposure to unforgiving climates can often lead to spalling. Consequently, understanding and addressing concrete spalling is a critical aspect in maintaining and improving our man-made surroundings.

Table of Contents

Preventing Concrete Spalling During Construction

Understanding Concrete Spalling

Concrete spalling is a common issue in the construction industry.

It occurs when water enters concrete and forces the surface to peel, pop out or flake off. If ignored or overlooked, spalling could lead to larger structural issues. Therefore, understanding how to prevent concrete spalling is essential for any project [source].

Can You Prevent Concrete Spalling During Construction?

The short answer is YES. Preventing concrete spalling is not only possible, but it’s a recommended best practice in the realm of commercial and residential construction. There are a number of practical strategies which can be used to prevent this issue.

Proper Mixing and Curing

To prevent spalling, start with the basics: the concrete mix. An incorrectly proportioned mix can increase the likelihood of water infiltration and therefore, spalling. Following this, concrete should be adequately cured to ensure maximum strength and durability.

- Use the correct amount of water and follow manufacturer’s guidelines

when mixing. Too much water can lead to a weak surface prone to spalling. - Allow ample time for curing. Rapid drying can lead to tensile stress within the concrete, increasing the chance of spalling.

Use of Quality Materials

Quality of materials also plays a huge role in preventing spalling.

- Use good quality aggregates. Poor quality aggregates can lead to disintegration and subsequent spalling.

- Do not use deicers containing ammonium sulfate or ammonium nitrate, as these can rapidly deteriorate the concrete and make it more susceptible to spalling.

Repairing Small Areas of Spalling

Despite your best efforts, you might notice small areas of spalling. Don’t panic. Every problem has a solution.

Immediate Repairs

If you notice small areas of concrete spalling, immediate intervention can prevent further damage.

- Remove all loose material from the spalled area.

- Apply a suitable repair material – this can be a pre-packaged mix or a mix created on-site.

- Make sure the repair material is compacted to eliminate air pockets.

- Apply a sealer on the repaired area to prevent future water intrusion.

In essence, preventing and managing concrete spalling is an essential skill for any construction project. From the right mix to quality materials and timely repairs, various strategies can be utilized to combat this pervasive issue. [source].

Cost of Repairing Concrete Spalling

The cost of repairing concrete spalling varies significantly depending on several factors. Most of these costs come from the materials required for the repair and the labor involved in completing the job.

Factors Affecting Repair Costs

Concrete spalling repair isn’t a one-size-fits-all solution—different factors affect the overall cost.

Extent of Damage

The severity and reach of the spalling fundamentally determine the price of the repair. Smaller areas typically cost less to repair, while extensive damage may require a total overhaul, driving up costs.

Type of Concrete Surface

The need to match the existing substrate’s aesthetics, particularly for decorative or specialized surfaces, can also impact the overall cost. Custom work or color matching may add significant expense.

Location and Accessibility

Projects in hard-to-reach areas might need special equipment or extra labor to conduct the repair, increasing the overall cost.

Average Costs of Concrete Spalling Repair

Concrete spalling repair costs can range from as low as $3 to $7 per square foot for simple patch jobs, with average costs sitting around $9 to $20 per square foot [source].

Please note that these are general estimates, and the actual cost may fluctuate based on local labor rates and material costs.

Additional Costs

Professional Evaluation

In some cases, before any repair work can be started, a professional evaluation may be necessary. This evaluation can identify the cause of the spalling and provide suitable repair options, adding to the overall cost.

Sealing

Post-repair, concrete surfaces should be re-sealed to prevent future water intrusion and potential spalling, adding an additional charge to the total repair costs.

Long-Term Savings

Despite the associated costs, repairing concrete spalling as soon as it’s noticed can result in long-term savings. By addressing the issue early, you can prevent further damage and the need for more extensive (and expensive) repairs or complete replacement in the future.

Bottom line: while concrete spalling repair costs can vary, investing in preventative measures and timely repairs can ultimately save you money in the long run. [source].

Additional Solutions to Prevent Concrete Spalling

Appropriate Use of Reinforcement

Reinforcement in concrete is inevitable, especially in structures that require additional strength. However, improper placement of reinforcement materials like rebar can cause spalling. To prevent this from happening:

- Keep rebar at least two inches away from the surface. Placement too close to the surface could lead to spalling.

- Ensure proper coverage of rebar to avoid corrosion, which can lead to spalling.

Climate Considerations

Various weather conditions can increase the susceptibility of concrete to spalling, especially in regions frequently exposed to freeze-thaw cycles. Thus, protecting concrete structures from severe weather conditions is another way to prevent spalling:

- In colder climates, use of air-entrained concrete can improve durability by providing space for water to expand when it freezes, thereby reducing internal stress.

- In hot and dry climates, proper curing methods should be used to prevent rapid evaporation of water from the concrete, decreasing chances of spalling.

Treating Existing Structures

Structures already suffering from spalling can be protected from further damage:

- Seal older concrete surfaces: Using a quality sealer can prevent the ingress of moisture, thus protecting the concrete from spalling. High-quality penetrating sealers work best.

- Controlled pressure washing: Regularly clean outdoor concrete surfaces with pressure washing to remove contaminants that can accelerate spalling. However, make sure the pressure setting isn’t too high, as it could damage the surface.

In the end, preventing concrete spalling revolves around quality construction practices, from mixing and curing to placing reinforcements correctly and appropriately treating existing structures. Maintaining these best practices will ensure concrete longevity. [source].

A Conclusion On Concrete Spalling

In our experience, practicing proactive measures in construction translates to a significant reduction in concrete spalling. It is evident that the correct mixing and curing of concrete, combined with the use of quality materials, offer a strong line of defense against spalling. Employing these strategies is not just good practice, but a necessity for structural integrity.

Additionally, we’ve found that early recognition and repair of smaller spalled areas can prevent more comprehensive damage. A swift response to initial signs of spalling helps to maintain the durability and longevity of our constructions.

In conclusion, combating concrete spalling demands an understanding and appropriate application of these key strategies, ensuring the resilience and durability we endeavor to achieve in all of our construction projects.