Concrete Setting Strategies

Concrete setting is a crucial aspect of any construction project. Its success lies in understanding the process and employing strategic techniques to optimize results.

In this article, we’ll discuss common mistakes in concrete setting and offer advice on how to avoid them, ensuring your projects stand the test of time.

Table of Contents

A List Of Mistakes To Avoid

Mistake 1: Rushing the setting process

Rushing the setting process can lead to weak structures. Concrete needs time to harden and gain strength; therefore, allowing adequate time for setting is pivotal.

Prevention

Plan your construction schedule to allow ample time for concrete to set. Avoid hurrying the process.

Mistake 2: Ignoring weather conditions

Weather plays a significant role in a concrete setting. Extreme temperatures, rain, or high humidity can adversely impact the process.

Prevention

Adapt the setting process to prevailing weather conditions. Use weather forecasts to plan ahead and consider using additives or protective measures during adverse weather.

Concrete setting doesn’t have to be a stumbling block in your construction project. By avoiding these mistakes and applying the relevant preventative measures, you can ensure a smoother process and superior results. Stay tuned for more practical tips on optimizing your construction projects.

More Common Mistakes to Avoid During Concrete Setting

Mistake 1: Inadequate Site Preparation

One of the biggest mistakes often overlooked during the initial stages of concrete setting is poor site preparation. A well-prepared site not only makes the process easier, but it also ensures the concrete will set correctly and have a solid foundation.

How to avoid:

Always take the time to properly prepare and compact the subgrade, ensure the forms are correctly set up, and the site is cleared out before pouring the concrete. Accurate quantity measurements are also crucial to avoid unnecessary waste and cost overruns.

Mistake 2: Adding Too Much Water

Another common blunder during concrete setting is adding too much water to the mix. Excess water dilutes the cement paste, weakening the strength of the concrete.

How to avoid:

Follow the manufacturer’s instructions when it comes to the water-to-concrete ratio. A correct mix should have a consistency similar to peanut butter.

Mistake 3: Ignoring Weather Conditions

Ignoring weather conditions can have a devastating impact on the setting process. Concrete setting is highly sensitive to weather changes, especially rain and extreme temperatures.

How to avoid:

Weather forecasts are your friend. Avoid pouring concrete on extremely hot days, cold days—or when rain is expected within 24 hours. When dealing with weather-related challenges, use products designed to mitigate the adverse effects of weather on concrete surfaces.

Mistake 4: Improper Curing

Many people underestimate the importance of proper curing in the concrete setting process. Curing maintains the moisture within the concrete for a period post-setting, which ensures the concrete achieves full strength.

How to avoid:

Develop a proper curing plan from the outset. This should ideally include methods like water curing, using concrete curing blankets or applying a concrete curing compound.

| Error | How to Avoid |

|---|---|

| Inadequate Site Preparation | Prepare the subgrade, set up forms correctly, and clear the site before pouring |

| Adding Too Much Water | Follow the manufacturer’s water-to-concrete ratio |

| Ignoring Weather Conditions | Check weather forecasts and use products designed to counteract adverse effects |

| Improper Curing | Develop a proper curing plan that could include water curing, using curing blankets or applying curing compound |

By avoiding these common mistakes, construction professionals can ensure a successful concrete setting process. For more detailed information on each mistake as well as further practical advice, consider referring to established construction publications such as Concrete Construction.

The Impact of Weather on Concrete Setting: A Comprehensive Guide

Understanding how different weather conditions affect concrete setting is an essential aspect of proper construction management. In this post, we’ll delve into various factors, including temperature, humidity, wind speed, and precipitation.

1. Temperature’s Impact on Concrete Setting

Concrete setting heavily depends on the temperature of the environment. High and low temperatures can significantly affect the rate at which the concrete cures.

Effects of High Temperature

Extreme heat speeds up water evaporation from the concrete mix, often resulting in rapid hardening. This expedites the setting time which can lead to a weaker final structure due to inadequate curing.

Effects of Low Temperature

On the contrary, low temperatures slow down the chemical reactions involved in concrete setting, extending the curing period. If the temperature drops below freezing, this could even lead to freezing of the water content, causing damage to the concrete.

2. Humidity’s Impact on Concrete Setting

Humidity, or the amount of moisture in the air, can influence the rate of evaporation and thus play a significant role in concrete setting.

High Humidity

High humidity slows the evaporation rate which gives the concrete ample time to cure. This often results in a more durable structure.

Low Humidity

Inversely, low humidity accelerates water evaporation, possibly leading to rapid hardening and potential cracking.

3. Wind Speed and Precipitation’s Effects on Concrete Setting

Wind speed and precipitation are two other factors that could interfere with the concrete setting process.

Strong Winds

Strong winds can lead to rapid evaporation and thus, similar to high temperature and low humidity, affect the hydration process of concrete.

Heavy Rainfall

Heavy rain can wash away the cement in the mix, causing a decrease in strength of the final structure.

Here’s a summary table for easy understanding of these factors.

| Weather Condition | Effect on Concrete Setting |

|---|---|

| High Temperature | Speeds up setting, might result in weaker structure. |

| Low Temperature | Slows down setting, risk of freezing damage. |

| High Humidity | Slows evaporation, contributing to stronger structure. |

| Low Humidity | Accelerates evaporation, could lead to cracks. |

| Strong Winds | Can lead to rapid evaporation, impacting curing. |

| Heavy Rainfall | Can wash away cement, decreasing strength. |

Leverage this information to properly manage your construction procedures and ensure the extended durability and strength of your structures.

For further guidance on construction practices under diverse weather conditions, consider checking out resources like those available at the American Concrete Institute.

Speeding Up the Setting Time for Concrete: Strategies and Methods

Understanding Concrete Setting

Before delving into how to accelerate the setting time for concrete, it’s essential to understand what concrete setting entails. The setting is a critical phase in the concrete curing process where the concrete hardens after being poured. This period is vital as it determines the structural integrity and durability of the concrete.source. However, in certain scenarios, there may be a need to speed up this process, which brings us to our discussion today.

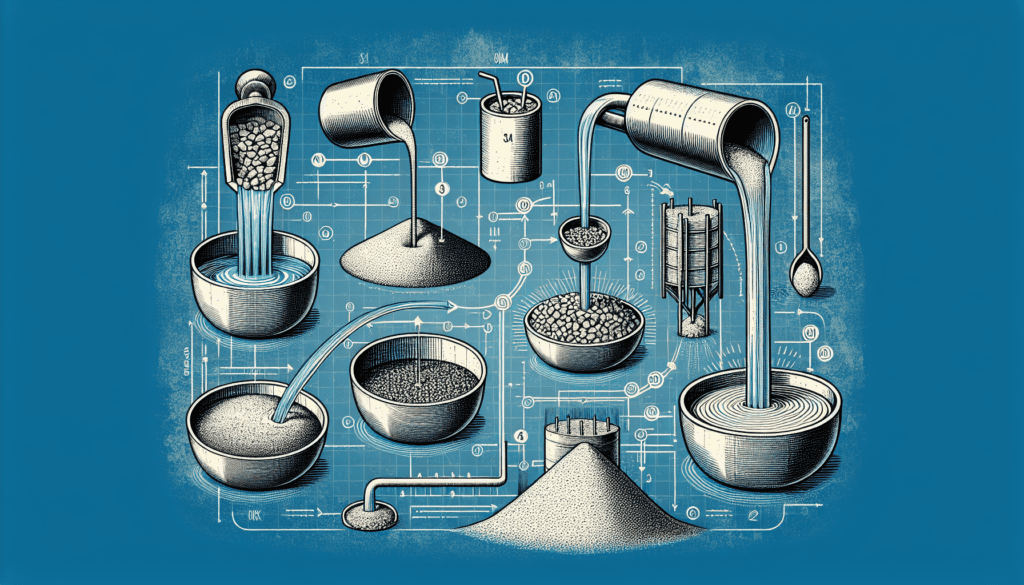

How to Speed up Setting Time for Concrete

There are several proven methods and strategies to hasten the concrete setting process. Here’s an exploration of some effective tactics.

Incorporating Chemical Admixtures

One of the most common strategies involves the use of chemical admixtures. Adding specific chemicals to the concrete mix can significantly accelerate the setting process.

- Calcium chloride: A common accelerating admixture that can reduce setting time.

- Non-chloride accelerators (NCAs): Ideal for situations where corrosion could be an issue.

Remember to follow recommended manufacturer guidelines on dosage to prevent compromising the end product’s integrity. For more details on admixtures, consult the ASTM Standards.

Increase the Cement Content

Another strategy involves increasing the cement ratio in the concrete. More cement can result in faster setting times. However, take caution as this method can also result in higher heat of hydration and potential cracking.

Proper Curing Techniques

Proper curing methods can also affect the speed of the setting process. Implementing methods such as steam curing can help speed up the process.

Considerations to Keep in Mind

Though speeding up the setting process for concrete can be beneficial in certain scenarios, there are considerations to bear in mind.

Structural Integrity

Accelerating setting time can potentially lead to a compromise in the overall strength and durability of the concrete if not done correctly.

Weather Conditions

The ambient temperature can impact how quickly concrete sets. Cold weather can slow down the process, while hot, dry conditions can expedite it, which should be taken into account in the curing process.

In conclusion, while speeding up the concrete setting time can be advantageous, it’s crucial to balance speed with maintaining the strength and durability of the final product. Understanding the complexities of the process is key. All techniques used should adhere to industry standards and manufacturers’ specifications.

A Concrete Setting Summary

In summary, avoiding common errors during the concrete setting phase is vital for achieving a stable, robust result.

Proper site preparation, adhering to the accurate water-to-concrete ratio, considering weather forecasts, and having an effective curing plan should be taken into account to avoid pitfalls.

We’ve found that minimizing mistakes can lead to cost and time efficiency, as well as the overall success of your construction project.

From our perspective, awareness of these potential errors and knowing how to circumvent them can guarantee a smooth concrete setting process, while helping to enhance the durability and strength of the concrete.

In our experience, ongoing education and staying updated with the latest construction guidelines will greatly aid in the minimization of these mistakes.